Sustainable Materials Selection for Body Repair and Refinishing

Choosing Environmentally Conscious Adhesives

In the world of body repair and refinishing, the adhesives we choose make a real difference. Opting for sustainable alternatives isn't just trendy - it's becoming essential. Modern eco-friendly adhesives often come from surprising sources like cornstarch or vegetable oils, offering a cleaner alternative to traditional petroleum-based products. What's remarkable is how these green options now match conventional adhesives in strength and durability while creating healthier workspaces with fewer chemical fumes.

The true test of an adhesive's environmental impact goes beyond its immediate use. We need to examine everything from how it's made to how we dispose of it. Seeking out products with recognized environmental certifications ensures we're supporting responsible manufacturing while getting quality results.

Selecting Sustainable Finishes

The paint we spray matters more than we might think. Water-based finishes have emerged as game-changers, dramatically cutting down on the volatile organic compounds (VOCs) that pollute our air and harm our health. These innovative formulas don't just benefit the environment during application - their entire lifecycle, from factory to final coat, leaves a smaller carbon footprint.

Beyond the basic formula, forward-thinking manufacturers are incorporating recycled materials into their finishes. This approach reduces waste and supports the circular economy, proving that sustainability and quality can go hand in hand in auto refinishing.

Utilizing Recycled and Recycled-Content Materials

The green revolution in auto repair extends to the very parts we use. More shops are discovering that recycled components perform just as well as new ones while significantly reducing environmental impact. By choosing these materials, we're not just fixing cars - we're helping preserve natural resources and ecosystems.

Even fillers and other repair materials now come in recycled versions, closing the loop in automotive repair processes. This shift represents a fundamental change in how the industry approaches sustainability, making environmental responsibility part of every repair job.

Optimizing Application Techniques for Reduced Waste

How we apply materials matters as much as what we apply. Skilled technicians using precision methods can dramatically cut waste while maintaining perfect results. The right techniques not only save materials but also translate to real cost savings for repair businesses.

Proper cleanup and storage complete the picture. Responsible handling of leftover materials ensures nothing harmful enters the environment while maximizing the value of every product purchased. These practices demonstrate how small changes can create big environmental benefits.

Optimizing Processes for Reduced Waste and Energy Consumption

Streamlining Workflow

Effective process optimization begins with a fresh look at how work flows. Trimming unnecessary steps and combining overlapping tasks can transform efficiency. When workflows become leaner, productivity surges while costs and frustrations drop. The result? Happier teams and healthier bottom lines.

Implementing Automation

Smart automation handles repetitive tasks with perfect consistency, freeing human talent for more creative work. This isn't about replacing people - it's about amplifying their potential while eliminating costly mistakes. From simple tools to advanced robotic systems, automation is reshaping how repair shops operate.

Data-Driven Decision Making

Numbers don't lie. Tracking performance metrics reveals exactly where processes need improvement. With solid data, managers can make targeted changes that deliver measurable results rather than guessing at solutions. This scientific approach takes the uncertainty out of process improvement.

Employee Training and Empowerment

Knowledgeable employees are a shop's greatest asset. When technicians understand the why behind new methods, they become active partners in improvement rather than passive participants. Ongoing training creates a culture where everyone looks for ways to do things better.

Improving Communication and Collaboration

Great communication turns individual efforts into team successes. Clear expectations and open information sharing help every department work in harmony. The best ideas often come from unexpected places when communication flows freely.

Regular Monitoring and Evaluation

Improvement isn't a one-time event. Continuous tracking ensures optimized processes stay optimized, with quick corrections when needed. Regular check-ins keep everyone focused on maintaining peak performance.

Measuring and Reporting Results

Success deserves documentation. Clear reporting shows exactly what improvements have achieved, building support for future innovations. When everyone sees the benefits, enthusiasm for optimization grows.

Implementing Water Conservation Strategies in Body Shops

Understanding the Importance of Water Conservation

Water matters more than we often realize, especially in body shops where cleaning consumes significant amounts. Smart water use isn't just eco-friendly - it's financially savvy. As water becomes scarcer globally, conservation shows customers and communities that a business cares about more than profits.

Implementing Water-Saving Techniques in Washing Stations

Simple upgrades like high-efficiency nozzles can slash water use without compromising cleanliness. The latest equipment delivers powerful cleaning action while using far less water - a win for both the environment and the budget.

Utilizing Recycled Water for Secondary Processes

Why use fresh water for tasks that don't require it? Gray water systems turn waste into resource, cutting both water bills and environmental impact. This practical approach demonstrates real commitment to sustainability.

Optimizing Cleaning Procedures for Efficiency

Sometimes the best solution is working smarter. Analyzing and refining cleaning methods can yield surprising water savings without sacrificing results. Proper training ensures these improvements become standard practice.

Enhancing Staff Awareness and Training

Conservation starts with understanding. When teams grasp the importance of water savings, they naturally find more ways to conserve. Regular reminders keep this priority top of mind in daily work.

Monitoring and Evaluating Water Usage

You can't improve what you don't measure. Tracking water use reveals waste areas and proves the success of conservation efforts. This data-driven approach ensures continuous improvement.

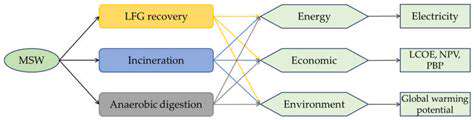

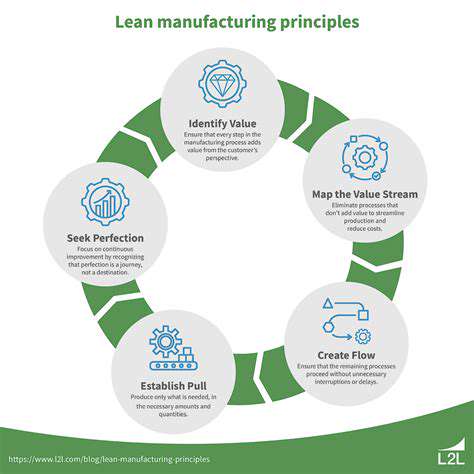

Adopting Lean Manufacturing Principles for Waste Minimization

Implementing Lean Principles for Enhanced Efficiency

Lean thinking transforms waste into value. This philosophy reshapes entire operations, turning every process into an opportunity for improvement. By focusing on what truly matters to customers, businesses eliminate countless hidden costs and inefficiencies.

Value Stream Mapping for Process Optimization

Seeing the whole picture changes everything. Visual process mapping exposes wasteful steps that drain resources without adding value. This clarity enables targeted improvements with maximum impact.

Employee Empowerment for Continuous Improvement

The best ideas often come from those doing the work. When employees at all levels contribute suggestions, improvements happen faster and work better. This engagement creates a dynamic culture of constant progress.

Waste Reduction Strategies for Enhanced Efficiency

Lean methods attack waste in all its forms. Whether it's excess inventory, unnecessary motion, or waiting time, systematic elimination streamlines operations. The result? Faster, cheaper, better results.

The Role of Technology in Lean Implementation

Modern tools supercharge lean efforts. From real-time tracking to automated systems, technology provides the visibility and control needed for true lean transformation. The right tech makes continuous improvement easier to achieve and sustain.

The Role of Technology in Driving Sustainable Practices

The Automation of Tasks

Technology's transformative power shines in task automation. By handling routine work precisely and tirelessly, smart systems free human talent for higher-value contributions. While this shift requires workforce adaptation, the efficiency gains benefit businesses and customers alike.

Enhanced Communication and Collaboration

Distance disappears with modern communication tools. Teams collaborate seamlessly across locations, sharing knowledge and solving problems in real time. This connectivity drives innovation while supporting flexible work arrangements.

Data-Driven Decision Making

In today's complex world, guesswork won't cut it. Technology turns raw data into actionable insights, guiding businesses toward smarter, more sustainable choices. This evidence-based approach reduces risk while maximizing results.

Increased Efficiency and Productivity

When technology and human skill combine, productivity soars. Automated systems handle repetitive tasks perfectly while people focus on creative solutions. This powerful partnership drives sustainable growth in every industry.