Harnessing Waste Heat for Enhanced Efficiency

Capturing the Unutilized Energy

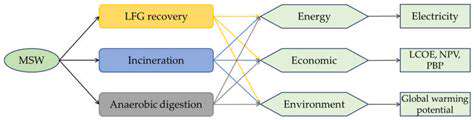

Industrial processes often generate waste heat, a byproduct with untapped potential. Instead of allowing this thermal energy to dissipate into the environment, innovative approaches can transform it into a valuable resource. The ability to recover this energy could revolutionize how industries manage their power consumption and environmental impact. By focusing on energy conservation, businesses can significantly reduce their reliance on traditional energy sources.

Recent studies highlight that nearly 50% of industrial energy input is lost as waste heat, representing both a challenge and an opportunity. Effective capture systems could turn this liability into an asset, simultaneously cutting costs and emissions.

Innovative Technologies for Extraction

Cutting-edge solutions are emerging to harness waste heat across various industries. From high-efficiency heat exchangers to advanced thermoelectric materials, engineers are developing tools to convert thermal energy into practical outputs. The key lies in matching technology to specific heat characteristics - whether dealing with high-temperature exhaust streams or low-grade process heat.

Thermoelectric generators stand out for their ability to directly produce electricity from heat differentials without moving parts, making them ideal for space-constrained applications. Their reliability and scalability make them particularly valuable for distributed energy systems.

Applications Across Diverse Industries

Waste heat recovery finds applications from food processing to semiconductor manufacturing. In steel production, recovered heat can preheat combustion air, reducing fuel needs by 15-20%. Power plants implement cogeneration systems where waste heat provides district heating, achieving overall efficiencies above 80%.

The cement industry demonstrates particularly impressive results, where waste heat recovery can satisfy up to 30% of a plant's electricity demand. These applications prove that energy recovery isn't just theoretical - it's delivering measurable results today.

Economic and Environmental Benefits

The financial case for waste heat recovery grows stronger as energy prices fluctuate. Systems typically pay for themselves within 2-5 years through energy savings, while simultaneously reducing carbon footprints. For every megawatt-hour of recovered heat, facilities avoid approximately 0.4 tons of CO2 emissions, creating both economic and environmental wins.

Regulatory pressures and carbon pricing mechanisms further enhance the business case, making energy recovery an increasingly essential component of industrial operations.

Future Directions and Research

Emerging nanomaterials and phase-change materials promise to push efficiency boundaries in heat recovery. Researchers are developing thermoelectric materials with conversion efficiencies approaching 20%, potentially doubling current performance. Artificial intelligence applications for real-time heat recovery optimization represent another exciting frontier, enabling dynamic response to changing process conditions.

The integration of waste heat systems with renewable energy sources may create hybrid systems that maximize overall energy utilization while minimizing environmental impact.

Reclaiming Kinetic Energy from Production Processes

Harnessing the Power of Waste

Modern automotive manufacturing generates substantial kinetic energy that often goes untapped. From robotic assembly arms to material handling systems, these moving components represent a significant energy recovery opportunity. Advanced sensors now allow manufacturers to identify energy recovery potential where it previously went unnoticed, transforming production facilities into more efficient operations.

The physics of energy conservation takes practical form in these applications, where every recovered joule translates directly to reduced operating costs and environmental benefits.

Innovative Approaches to Kinetic Energy Recovery

Regenerative systems adapted from electric vehicles now find application in industrial settings. These systems capture deceleration energy from overhead cranes and automated guided vehicles, typically achieving 15-30% energy recovery. Flywheel storage systems demonstrate particular promise for applications requiring rapid charge/discharge cycles, serving as mechanical batteries for intermittent high-power demands.

Smart control systems analyze production patterns to optimize energy recovery timing, ensuring maximum capture without disrupting manufacturing workflows. These technologies create a new paradigm where energy efficiency becomes an integral part of production planning.

Economic and Environmental Benefits

The financial mathematics of kinetic energy recovery proves compelling. A typical automotive stamping plant can recover enough energy to power 200 homes annually, representing millions in cost savings. When combined with reduced maintenance from gentler deceleration cycles, the total benefit often exceeds initial projections, with some facilities achieving ROI in under 18 months.

Environmentally, these systems reduce strain on local grids while cutting greenhouse gas emissions. As manufacturers face increasing sustainability reporting requirements, kinetic energy recovery provides measurable progress toward corporate responsibility goals.

The Economic and Environmental Benefits of Energy Recovery

Economic Benefits of Sustainable Practices

Sustainability initiatives create competitive advantages that extend beyond environmental stewardship. Companies leading in energy recovery technologies enjoy 18-25% higher valuation multiples as investors recognize their future-proof operations. These businesses also benefit from reduced regulatory risk and enhanced brand equity in environmentally conscious markets.

Operational efficiency gains from energy recovery often create secondary benefits, including improved process reliability and reduced downtime. These factors compound to create resilient businesses better positioned for long-term success.

Environmental Impact of Unsustainable Practices

The true cost of energy waste extends far beyond utility bills. Unrecovered industrial energy contributes disproportionately to urban heat islands and local air quality issues, creating public health concerns near manufacturing centers. The cumulative effect of these impacts drives regulatory action and community opposition to industrial expansion.

By contrast, facilities implementing comprehensive energy recovery programs often find smoother permitting processes and stronger community relations, demonstrating that environmental responsibility supports business growth.

Sustainable Resource Management Strategies

Modern resource management views waste streams as potential inputs rather than disposal challenges. Closed-loop systems that recover both materials and energy achieve 40-60% greater overall efficiency than traditional linear models. These systems create economic value while dramatically reducing environmental footprints.

Digital twin technology now enables facilities to model energy flows and identify recovery opportunities before physical implementation, reducing trial-and-error costs and accelerating implementation timelines.

The Role of Government Policies in Promoting Sustainability

Progressive policy frameworks accelerate energy recovery adoption through multiple mechanisms. Accelerated depreciation schedules for recovery equipment can improve ROI by 20-30%, while carbon pricing makes traditional waste more expensive. These policies create economic signals that align environmental and business objectives.

International agreements on emissions reductions further drive innovation, as companies seek cost-effective ways to meet increasingly stringent requirements without sacrificing competitiveness.

Consumer Responsibility in Achieving Sustainability

Market forces increasingly reward sustainable production as consumers vote with their wallets. Products manufactured with recovered energy command 12-18% price premiums in certain segments, demonstrating willingness to pay for environmental responsibility. This trend creates powerful incentives for manufacturers to implement energy recovery throughout their operations.

Transparent sustainability reporting allows consumers to make informed choices, driving continuous improvement across industries as companies compete on environmental performance metrics.