Spotting the Telltale Symptoms of a Compromised Cooling System

Noticing Minor Yet Crucial Changes

Early detection of cooling system issues requires vigilance in observing small but meaningful changes in your vehicle's behavior. These subtle variations might appear insignificant at first glance, yet they often serve as critical indicators of developing problems. Developing an awareness of these nuanced signals can mean the difference between a simple repair and catastrophic engine failure. Each vehicle exhibits its own unique patterns, making familiarity with your car's normal operation essential for spotting anomalies.

Watch for unusual occurrences like gradual temperature fluctuations, persistent low coolant levels, or unexpected dashboard warnings. While these might seem inconsequential when isolated, their persistent recurrence suggests underlying concerns that demand attention. Addressing these signs promptly typically results in more straightforward solutions and prevents extensive damage.

Evaluating Vehicle-Specific Vulnerabilities

Every automobile comes with its own set of potential weak points in the cooling system. Factors like your vehicle's age, mileage, maintenance history, and typical operating conditions all influence its cooling system's reliability. Recognizing your particular model's known trouble spots enables more targeted monitoring and preventive care. This knowledge forms the foundation for anticipating possible issues before they escalate.

Monitoring Critical Operating Parameters

Your vehicle's temperature gauge, coolant levels, and pressure readings provide vital information about cooling system health. Regular checks of these indicators offer valuable evidence about the system's condition. Establishing a routine for checking these parameters helps establish baseline readings for comparison when troubleshooting. While some variation in these measurements is normal, sustained deviations from expected ranges typically warrant professional assessment.

Accounting for Operational Conditions

External factors significantly affect cooling system performance. Extreme weather, challenging terrain, heavy loads, or prolonged idling can all strain the cooling system beyond normal limits. Understanding how environmental conditions affect your vehicle's cooling capacity helps differentiate between normal stress responses and genuine system malfunctions. This awareness allows for appropriate adjustments in maintenance schedules based on usage patterns.

Observing Performance Characteristics

Changes in how your vehicle performs can signal cooling system troubles. Symptoms like reduced power output, unusual noises from the engine compartment, or abnormal exhaust emissions often correlate with cooling inefficiencies. These behavioral changes frequently serve as the most noticeable indicators that prompt drivers to investigate potential cooling system problems. Recognizing these patterns early facilitates timely diagnosis and repair.

Consulting Automotive Professionals

When cooling system concerns arise, seeking expert evaluation becomes essential. Certified mechanics possess specialized diagnostic tools and knowledge to accurately assess cooling system health. Professional inspections provide the most reliable method for verifying suspected issues and determining appropriate solutions. Technicians can also recommend preventive measures tailored to your specific vehicle and driving habits. This proactive approach maximizes system longevity and minimizes unexpected failures.

Advanced Techniques for Cooling System Evaluation

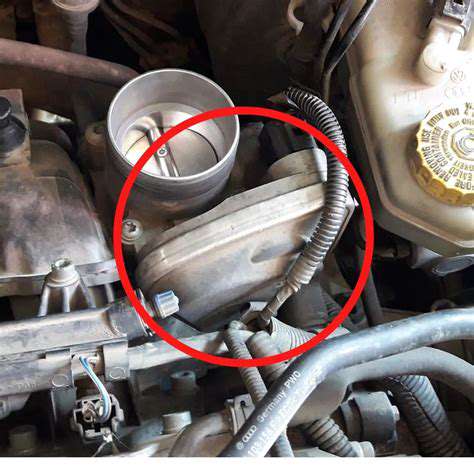

Diagnosing Pressure Irregularities

Pressure diagnostics form the cornerstone of thorough cooling system analysis. Low system pressure, frequently accompanied by audible leaks, may reveal compromised hoses, a defective radiator seal, or a failing pressure regulator. Alternatively, excessive pressure buildup could indicate thermostat malfunction, restricted coolant passages, or water pump inefficiency. Comprehensive examination of all pressure-sensitive components is necessary for accurate diagnosis.

Precise pressure measurement requires quality gauges and proper technique. Pressure values correlate directly with operating temperatures, and readings that persistently fall outside manufacturer specifications strongly suggest system abnormalities. Maintaining detailed pressure records under various operating conditions helps identify intermittent issues that might otherwise evade detection.

Interpreting Temperature Patterns

Abnormal temperature distribution throughout the cooling circuit often indicates specific component failures. Elevated operating temperatures might stem from restricted radiator airflow, sticking thermostat valves, or impaired coolant circulation. Conversely, difficulty achieving normal operating temperature could suggest excessive coolant flow, thermostat malfunction, or partial blockages.

Methodical temperature monitoring during diverse driving scenarios provides crucial diagnostic information. Observe how temperature responds to varying speeds, loads, and ambient conditions. This systematic approach helps distinguish between gradual deterioration and sudden component failures.

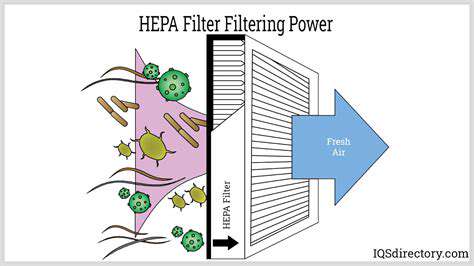

Locating System Leaks and Restrictions

Initial leak detection relies on visual inspection for moisture around connections, joints, and components. Even minor seeping that appears insignificant can result in substantial coolant loss over time, potentially causing performance degradation and collateral damage. Precise leak identification ensures targeted repairs.

For elusive leaks, specialized fluorescent dyes or pressure testing equipment often proves necessary. Similarly, internal blockages in radiators or heater cores require pressure testing and flow measurement for accurate location. Restoring unimpeded coolant circulation is fundamental to system efficiency.

The Economic Advantages of Preventive Cooling System Care

Cost Reduction Through Preventative Measures

Consistent cooling system maintenance delivers substantial long-term savings by preventing major component failures. Scheduled inspections, fluid analysis, and timely part replacements according to manufacturer guidelines stop minor issues from developing into expensive repairs. This forward-looking strategy reduces unplanned outages and associated operational losses, providing measurable financial benefits. Addressing concerns early avoids the exorbitant costs of emergency breakdowns.

The economic impact of sudden cooling system failure extends beyond part replacement to include labor costs, potential environmental remediation, and lost revenue during downtime. Preventive maintenance offers an economically sound alternative by eliminating these substantial unforeseen expenses.

Enhanced Equipment Longevity and Performance

Proper cooling system maintenance directly extends equipment service life. Maintaining optimal operating conditions reduces stress on pumps, heat exchangers, and fluid conduits, delaying replacement needs and decreasing capital expenditures over the equipment lifecycle.

Moreover, a well-maintained cooling system improves overall equipment efficiency. Proper thermal regulation and fluid circulation directly influence machinery output and energy consumption. These efficiency gains translate to lower operating costs and higher production capacity, positively affecting the bottom line. The performance benefits extend beyond simple cost reduction to enhance total operational capability.

Operational Continuity and Output Consistency

Cooling system failures frequently cause disruptive operational stoppages. A preventive maintenance program significantly reduces this risk by identifying and addressing potential failure points during scheduled service intervals. Coordinating maintenance during planned downtime minimizes production disruptions and maintains workflow continuity.

By preventing unscheduled outages, preventive maintenance ensures steady production output and maintains workforce productivity. This operational reliability contributes directly to financial performance and manufacturing consistency. Maintaining uninterrupted operations represents a critical advantage of systematic maintenance programs.

Environmental Stewardship and Regulatory Compliance

Cooling system malfunctions can create environmental hazards, potentially resulting in regulatory penalties and reputational harm. Preventive maintenance helps avoid such incidents through regular leak detection and system integrity verification. Maintaining compliance with environmental standards and safety requirements represents a fundamental benefit of proactive system care.

Investing in cooling system maintenance demonstrates environmental responsibility while protecting corporate image. Preventing fluid leaks and spills preserves ecosystems and ensures adherence to environmental legislation, avoiding legal complications and safeguarding public perception.