Economic Incentives Driving the Recycling Industry

The booming EV market and rising environmental awareness are sparking major investments in battery recycling. Both governments and private firms are pouring money into these efforts. Recycling makes solid financial sense because the recovered materials are valuable. This economic upside is fueling new, more efficient recycling technologies.

Recycling also offers potential savings on raw materials, reducing reliance on mining. This could eventually lower battery production costs and EV prices. The benefits go beyond immediate savings, creating a greener, more sustainable supply chain.

Technological Advancements in Battery Recycling

New recycling technologies are making the process cleaner and more efficient. Scientists are developing better ways to extract valuable metals from old EV batteries. These range from innovative chemical methods to advanced mechanical sorting systems. These breakthroughs help recover more materials while reducing environmental harm. Such progress is crucial for the EV industry's sustainable growth.

Environmental Benefits of Recycling

Recycling EV batteries significantly cuts the industry's environmental impact. It keeps toxic chemicals out of landfills and reduces the need for destructive mining. Recycling also uses less energy than extracting new metals. Together, these benefits make EV production and use more sustainable overall.

Challenges and Future Outlook

Despite progress, battery recycling still faces hurdles. Different battery types with varying chemistries complicate recycling efforts. Global EV adoption requires coordinated action between governments, companies, and researchers to standardize recycling methods. The future looks promising though, with ongoing research likely to yield even better recycling solutions. The success of these efforts will shape the future of electric vehicles.

Material Complexity and Heterogeneity: A Recycling Hurdle

Material Complexity

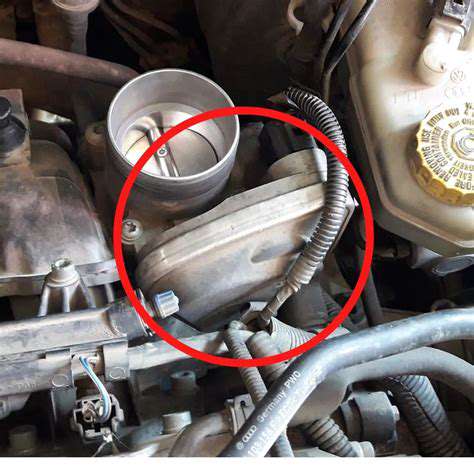

EV batteries contain a complex mix of materials - lithium, cobalt, nickel, manganese and more - each needing different processing methods. The exact composition varies between battery types and even individual cells, making uniform recycling difficult. This diversity requires specialized separation techniques to recover valuable components cleanly, adding cost and complexity.

Additional components like binders and electrolytes further complicate separation. These materials are tightly integrated, requiring advanced chemical and physical methods to extract them. Each battery type needs a customized approach, making sustainable, cost-effective recycling challenging.

Heterogeneity in Battery Structure

Battery physical structures also complicate recycling. Cells contain multiple layers (cathode, anode, separator, casing) with different properties needing distinct extraction methods. Designs vary by manufacturer, preventing a one-size-fits-all recycling solution.

Varying thicknesses and densities within these layers make physical separation tricky. Recovering valuable materials from this complex arrangement demands advanced processing techniques, requiring specialized equipment and trained staff. This affects recycling scalability and cost-effectiveness.

Recycling Challenges and Future Outlook

The combination of material complexity and structural variation creates major recycling obstacles. The diverse materials and designs require specialized techniques for efficient, cost-effective material recovery. Custom approaches for each battery type and the need for advanced equipment compound the challenge.

Current research focuses on innovative separation methods like advanced chemical leaching and mechanical processes. Developing economically viable, environmentally responsible recycling solutions is crucial for a sustainable EV future. Progress in these areas will determine the long-term viability and environmental impact of electric vehicles.

New recycling technologies will be key to establishing a circular economy for battery materials. This includes better separation techniques, process improvements, and cost-effective large-scale recycling infrastructure.

Economic Viability and Scalability: A Balancing Act

Economic Viability of Battery Recycling

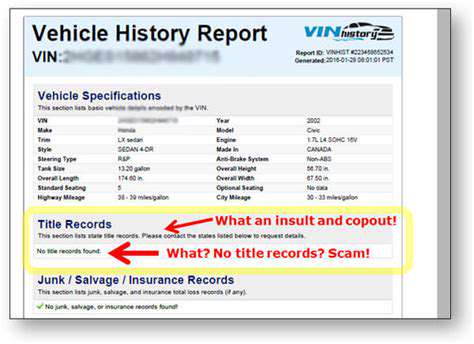

EV battery recycling's economic feasibility depends on raw material costs, process efficiency, and market demand for recycled materials. High startup costs for specialized equipment can deter smaller recyclers. Successful operations must carefully manage these costs to stay profitable long-term.

Price fluctuations in recovered metals (lithium, cobalt, nickel, manganese) affect profitability. Stable prices and reliable supply chains are essential to attract investment and grow the recycling industry.

Scalability Challenges and Opportunities

Scaling up recycling to meet growing demand presents logistical and technical challenges. Transporting large battery quantities safely and handling diverse chemistries are significant hurdles. However, better transportation, logistics, and standardized protocols could help.

Modular recycling plants that can expand with demand offer potential. Partnerships between recyclers, manufacturers, and governments could develop stronger recycling infrastructure.

Raw Material Costs and Market Demand

Fluctuating raw material prices directly impact recycling viability. Low prices may not justify recycling investments, while higher prices make it more attractive. Understanding market demand for recycled materials is crucial - weak demand hurts profitability, while strong demand encourages investment and innovation.

Recycling Technology and Process Optimization

Recycling efficiency and cost-effectiveness depend on technological advances. Improvements in chemical separation methods (hydrometallurgy, pyrometallurgy) are vital for extracting metals cleanly. Ongoing research aims to boost efficiency and cut costs.

Process optimization to recover more materials with less waste is essential. Better battery designs using more recyclable materials and standard formats could also improve recycling efficiency.

Environmental Considerations and Sustainability

While economics matter, environmental impact is equally important. Minimizing the recycling process's environmental footprint - through reduced water use, less air pollution, and better waste management - ensures long-term sustainability.

Policy and Regulatory Frameworks

Government policies significantly influence EV battery recycling. Incentives for sustainable technologies, battery collection programs, and clear disposal regulations can build a robust recycling industry. A balanced framework addressing both economic and environmental concerns is key to long-term success.

Technological Advancements and Research: Driving Innovation

Technological Advancements in Communication

The fast pace of technological change has revolutionized communication, altering how we interact, share information, and do business. From telegraphs to social media, each advancement has expanded our communication abilities. These innovations have connected people globally while enabling new forms of collaboration. Ongoing communication technology improvements continue transforming our social and professional worlds, boosting efficiency and global connections.

The internet and mobile devices enable instant global communication. This accessibility fosters new collaborations, lets businesses operate worldwide, and connects people across borders. Instant information sharing has transformed modern life in countless ways.

Reshaping the Workforce

Technology has dramatically changed modern work, creating new jobs while demanding new skills. Automation and AI are transforming industries, changing job demands and creating opportunities in emerging fields. Remote work and digital platforms have redefined offices, offering more flexibility. Staying competitive requires continuous learning and skill development.

Education must evolve to prepare workers for future job markets. This means teaching technical skills alongside adaptability, problem-solving, and collaboration. Lifelong learning has become essential in our rapidly changing economy.

Data analytics and automation tools are changing job requirements, creating opportunities for those with analytical skills. Continuous skill development is now crucial for career success and growth.

Restructuring Industries

Technology has reshaped entire industries, changing business models and competition. E-commerce has disrupted traditional retail, forcing adaptation. Manufacturing technology boosts efficiency, altering production and workforces.

Healthcare is transforming through telemedicine, advanced diagnostics, and personalized treatments. These changes improve patient care while creating new opportunities for healthcare professionals. Technology is streamlining processes while enhancing patient outcomes and experiences.