Rig Selection Considerations

Choosing the right rig for your project is crucial for both safety and productivity. A poorly chosen rig can lead to significant delays and even safety hazards. Careful consideration of the specific needs of your job site, including terrain, weather conditions, and the weight of the load, is paramount. This includes factors like the size and type of equipment needed to transport the material, the overall weight capacity of the rig, and the stability of the support structure.

Load Capacity and Stability

One of the most critical factors in rig selection is its load capacity. Exceeding the rig's maximum weight limit can result in catastrophic failure, putting workers and equipment at risk. It's essential to accurately calculate the total weight of the load and ensure the rig can handle it safely. Rig stability is equally important, as it directly impacts the safety of the operation. A stable rig minimizes the risk of tipping or shifting, preventing accidents and ensuring a smooth operation.

Terrain and Environmental Conditions

The terrain where the rig will operate significantly impacts the type of rig that's suitable. A rugged, uneven surface may require a rig with specialized features for stability and traction. Similarly, environmental factors like weather conditions and potential hazards must be factored in. Heavy rain or snow can dramatically affect the stability of a rig, and strong winds can impact its operation. Careful assessment of these conditions is essential to prevent accidents.

Operational Requirements

Consider the specific tasks the rig will need to perform. Different types of rigs are designed for various applications, such as lifting heavy materials, transporting equipment, or setting up temporary structures. Understanding these operational needs is vital for selecting the right rig and ensuring the job can be completed efficiently and safely. A rig that's too small or underpowered for the job will be inefficient and may lead to delays and errors.

Maintenance and Safety Features

Rig maintenance is critical for safety and longevity. A well-maintained rig is less likely to fail, reducing the risk of accidents. Furthermore, prioritizing rigs with robust safety features, such as enhanced braking systems and secure load-holding mechanisms, is crucial. These features directly impact the safety of the workers and the integrity of the operation. Regular inspections and adherence to maintenance schedules are essential components of a safe and efficient operation.

Manifold Design and its Effects on Emissions

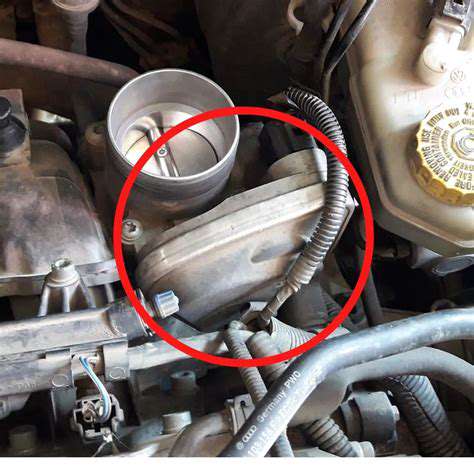

Manifold Design and Flow Dynamics

Proper manifold design is critical for efficient and consistent performance in internal combustion engines. The shape, size, and arrangement of the passages within the manifold directly impact the flow of fuel and air into the engine cylinders. A well-designed manifold minimizes pressure drops and turbulence, ensuring a smooth and controlled flow of the mixture, ultimately improving combustion efficiency. This optimization leads to better power output and reduced emissions. Careful consideration of manifold geometry is essential to maximize the transfer of energy from the fuel to the engine.

The choice of materials and manufacturing processes also plays a crucial role. Different materials offer various properties regarding durability, thermal conductivity, and resistance to corrosion, all of which impact the overall performance and lifespan of the manifold. Engineered designs often employ advanced manufacturing techniques, such as 3D printing or sophisticated casting methods, to create intricate internal geometries that enhance airflow and improve performance. These manufacturing processes allow for precise control over the internal channels, further optimizing the flow dynamics within the manifold.

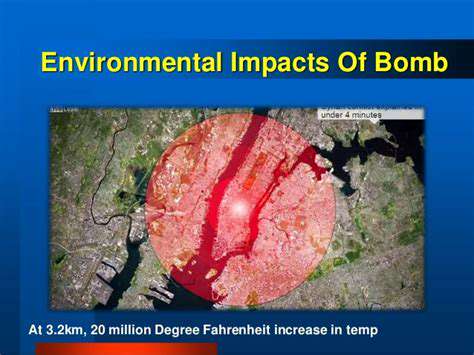

Manifold Design and Emissions Control

Engine emissions are a significant concern, and manifold design plays a critical role in mitigating them. By optimizing the airflow and combustion processes, manifolds can reduce the formation of harmful pollutants. Careful consideration of the manifold's geometry, including the length, diameter, and curvature of the passages, can minimize turbulence and recirculation, which are often linked to increased emissions. Properly engineered manifold designs lead to a more complete combustion process and a reduction in unburned hydrocarbons and other pollutants. This translates to a cleaner exhaust and a lower environmental footprint.

Additionally, manifold design is often integral to the integration of emission control devices. These devices, such as catalytic converters, require a specific flow pattern to function optimally. The manifold design must be compatible with these devices, facilitating efficient flow through the catalytic converter and maximizing the conversion of harmful pollutants into less harmful substances. Proper manifold design ensures that the exhaust gases are channeled effectively through the emission control system, leading to a reduction in harmful emissions.

Manifold Design and Engine Performance

A well-designed manifold significantly impacts the engine's overall performance characteristics. The efficiency of the fuel delivery system is directly linked to the manifold's ability to distribute the fuel-air mixture evenly throughout the cylinders. This even distribution is crucial for consistent power output and reduced engine stress. A smooth and controlled flow of the mixture throughout the combustion chambers ultimately leads to greater power production and enhanced torque at various engine speeds. This efficient delivery system translates into better fuel economy and improved responsiveness.

The manifold's design also influences the engine's responsiveness and throttle response. A properly designed manifold ensures a rapid and consistent flow of fuel and air to the cylinders, leading to a more immediate and precise engine response to acceleration commands. This responsive performance is vital for a smooth and enjoyable driving experience. A well-optimized manifold ensures that the engine delivers its full potential performance across a broader range of operating conditions.