Optimizing Packaging for Reduced Transportation Costs and Emissions

Minimizing Material Usage

Cutting down on packaging materials isn't just about saving money - it's about protecting our planet. The right material choices make all the difference, with lightweight recyclable options leading the charge. Forward-thinking companies are experimenting with plant-based plastics and advanced composites to shrink their environmental impact. These efforts don't just help the Earth - they boost the bottom line through reduced material expenses.

Smart design starts with rigorous testing. Modern simulation tools allow engineers to model how packages perform in transit, revealing where they can safely trim material without risking product safety. This scientific approach to packaging design yields impressive reductions in both material use and waste production.

Improving Packaging Design for Efficiency

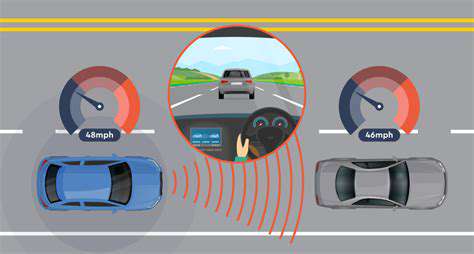

Great packaging design does more than protect products - it streamlines the entire supply chain. Thoughtful designs considering warehouse handling and transportation stacking can revolutionize logistics efficiency. When packages are easy to move and stack, businesses see fewer damaged goods, lower labor costs, and faster deliveries.

The perfect package fits its contents like a glove. Engineers must account for every dimension, weight characteristic, and fragility level to create packaging that minimizes empty space while maximizing protection. This precision leads to fewer damaged goods and more efficient shipping.

Sustainable Packaging Choices

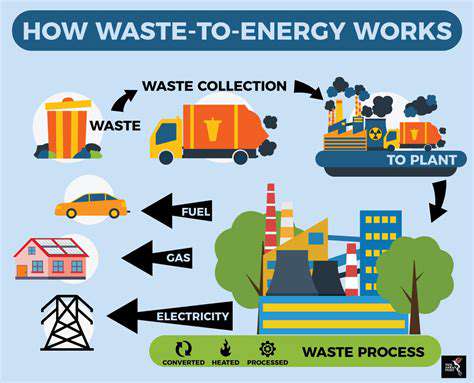

True packaging optimization embraces environmental responsibility at every turn. Choosing recyclable or biodegradable materials, phasing out single-use plastics, and cutting waste throughout the supply chain isn't just good PR - it's good business. These practices resonate with eco-conscious consumers while helping preserve our planet.

Effective recycling programs form the backbone of sustainable packaging. Clear material labeling and accessible recycling infrastructure ensure packaging gets a second life rather than ending up in landfills. Smart waste management reduces environmental harm while promoting responsible consumption.

Cost-Effectiveness of Packaging Solutions

Smart packaging requires careful financial analysis. Businesses must examine material expenses, production costs, and shipping fees to identify savings opportunities. Regular cost reviews uncover chances to improve efficiency and trim expenses without sacrificing quality. This ongoing analysis keeps companies competitive.

Winning cost strategies might include bulk purchasing, supplier negotiations, or process optimizations. Companies committed to continuous improvement in packaging economics enjoy both financial benefits and environmental advantages.

Impact on Product Protection and Safety

Packaging's primary job remains protecting its contents. The right materials and design must guard against damage, loss, and contamination throughout the shipping process. Each product's unique characteristics - from fragility to weight - demand customized solutions.

Rigorous real-world testing separates good packaging from great. Simulating temperature extremes, moisture exposure, and rough handling ensures packages can withstand whatever the supply chain throws at them. Only through thorough testing can companies perfect their protective packaging.

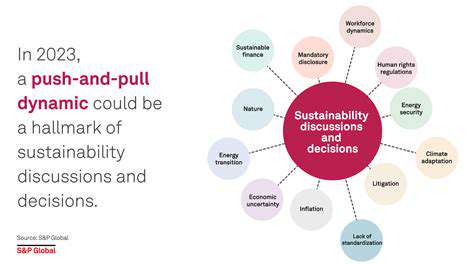

Collaboration and Industry Standards for a Sustainable Future

Collaboration Across the Supply Chain

Packaging sustainability requires teamwork across every link in the supply chain. From manufacturers to end consumers, everyone shares responsibility for reducing environmental harm. Success demands open communication, shared best practices, and collective innovation to minimize waste from raw materials to final disposal.

Establishing clear sustainability metrics creates accountability. When companies transparently share their supply chain impacts, it drives industry-wide improvements and fosters ongoing innovation in sustainable solutions.

Adhering to Industry Standards and Regulations

Keeping pace with packaging regulations is non-negotiable. Companies must stay current with environmental laws, recycling requirements, and industry benchmarks. Compliance demonstrates environmental commitment while avoiding penalties and meeting consumer expectations.

Standardized practices create fair competition while raising the bar for sustainable packaging. This collective commitment drives continuous industry improvement and responsible business practices.

The Importance of Material Selection

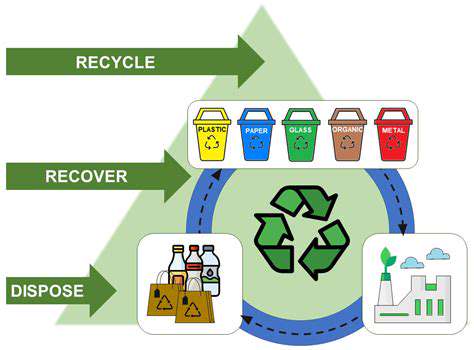

Choosing sustainable materials transforms packaging's environmental impact. Prioritizing recycled content, renewable resources, and biodegradable options reduces reliance on virgin materials while supporting circular economy principles.

Truly sustainable material choices consider the entire product lifecycle - from production energy needs to end-of-life disposal options. This comprehensive view ensures packaging remains environmentally responsible at every stage.

Promoting Transparency and Consumer Engagement

Honest communication builds consumer trust in sustainable packaging. Companies should clearly explain their materials' origins, recyclability, and environmental benefits. This transparency empowers customers to make eco-friendly choices.

Educated consumers drive demand for sustainable options. Through clear labeling, recycling incentives, and reusable packaging programs, businesses can turn customers into partners in environmental stewardship. These efforts cultivate responsible consumption habits that benefit both companies and the planet.