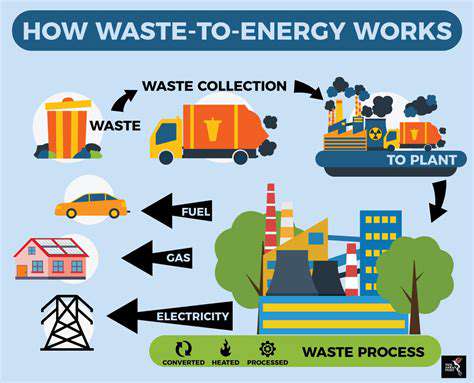

Improving Material Recovery

Material recovery and recycling programs form the backbone of sustainable waste management strategies. These initiatives focus on extracting every ounce of value from discarded materials through innovative approaches. Modern facilities employ cutting-edge sorting technologies like optical sensors and robotic systems to achieve unprecedented precision in material separation. This technological leap significantly reduces contamination while boosting the quality of recovered resources.

Infrastructure development plays an equally critical role in this process. Tailored collection systems that consider community-specific factors – population density, waste generation patterns, and facility accessibility – ensure optimal material recovery. Efficient transportation networks further guarantee that materials reach processing centers in prime condition, ready for their next life cycle.

Enhancing Recycling Infrastructure

A robust recycling ecosystem requires carefully planned networks of collection points and processing facilities. Clear, well-communicated guidelines for residents significantly improve participation rates and reduce contamination. When everyone understands proper sorting techniques, the entire system functions more smoothly.

Successful recycling programs thrive on collaboration. Partnerships between local governments, businesses, and community groups create synergies that amplify impact. These alliances facilitate resource sharing, knowledge transfer, and the adoption of best practices across different sectors, making recycling efforts more cost-effective and far-reaching.

Promoting Consumer Awareness and Engagement

Public participation makes or breaks recycling initiatives. Effective education campaigns that explain proper waste sorting and demonstrate recycling's environmental benefits can dramatically improve outcomes. Encouraging reusable products and responsible consumption patterns also reduces the waste stream's overall volume.

Incentive programs offer another powerful engagement tool. From deposit-refund schemes to community recognition programs, these initiatives motivate participation while fostering environmental responsibility. When people see tangible benefits from proper recycling, adoption rates soar.

Facilitating Market Development for Recycled Materials

Recycling programs need viable end markets to succeed. Encouraging industries to incorporate recycled content in products creates essential demand. Policy measures that incentivize recycled material use can jumpstart this process, helping build a true circular economy.

Continued research into new applications for recycled materials opens additional opportunities. As innovative uses emerge, markets diversify and expand, creating more sustainable economic models for recovered resources.

Beyond the Factory: Extending Zero-Waste Principles to the Entire Vehicle Lifecycle

Zero-Defect Manufacturing in the Supply Chain

The zero-defect philosophy now extends far beyond factory walls. Applying these principles throughout supply chains prevents defects at their source, saving significant resources and improving end product quality. Close supplier collaboration ensures consistent standards from raw materials to finished goods.

Transparent communication and shared quality metrics create alignment across all partners. This proactive approach prevents quality issues rather than reacting to them after they occur.

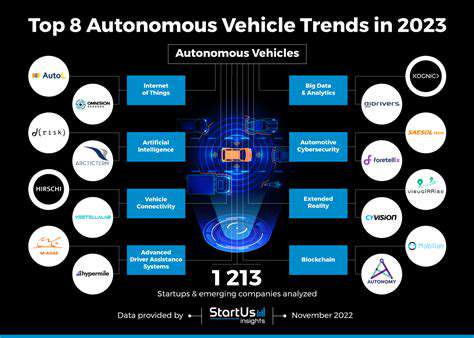

The Role of Technology in Zero-Defect Supply Chains

Advanced technologies revolutionize quality control. AI and machine learning analyze patterns to predict and prevent potential defects before they happen. Real-time monitoring systems provide immediate quality feedback, enabling instant corrective actions.

Predictive maintenance programs keep equipment operating at peak performance, preventing quality variations caused by machinery issues. These technological solutions create a more resilient production ecosystem.

Employee Training and Empowerment

A quality-focused culture requires investment in people. Comprehensive training ensures every team member understands their role in maintaining standards. When employees feel empowered to identify and address quality concerns, they become active participants in continuous improvement.

Creating channels for feedback and recognizing quality contributions reinforces this culture. Employees who see their input valued become more engaged in defect prevention efforts.

Customer-Centric Zero Defect Initiatives

Customer feedback provides invaluable quality insights. Systematic collection and analysis of customer experiences help identify potential improvements. Addressing these issues proactively enhances both product quality and customer satisfaction.

This feedback loop creates ongoing quality improvements while strengthening customer relationships.

Beyond Compliance: The Competitive Advantage of Zero Defect

Zero-defect implementation delivers tangible business benefits. Companies that consistently deliver flawless products build exceptional brand reputation and customer loyalty. These advantages translate directly to market share and profitability.

In today's competitive landscape, quality excellence represents a clear differentiator. Organizations that master zero-defect principles across their operations gain significant strategic advantage.