The Growing Need for EV Battery Recycling

The Environmental Imperative

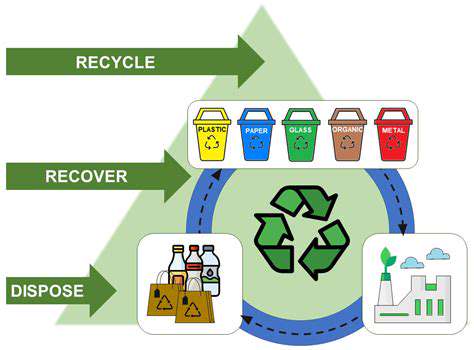

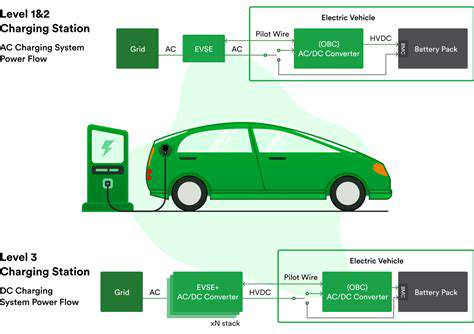

The escalating demand for electric vehicles (EVs) is undeniably transforming the automotive landscape. However, the inherent challenge of managing the end-of-life batteries associated with these vehicles is becoming increasingly critical. The environmental impact of improper battery disposal is significant, ranging from the leaching of harmful chemicals into soil and water to the release of greenhouse gases during landfill decomposition. Consequently, the need for environmentally responsible and sustainable EV battery recycling practices is paramount to mitigating these risks and ensuring a cleaner future.

Recycling these batteries is not merely a matter of good environmental stewardship; it's also an essential step in the circular economy. By recovering valuable materials from spent EV batteries, we can significantly reduce the need for primary resource extraction, thereby minimizing the environmental footprint of the entire EV lifecycle. This translates into less mining, less deforestation, and a more efficient utilization of existing resources.

Technological Advancements in Battery Recycling

Significant advancements in battery recycling technologies are emerging to meet the growing needs of the EV industry. These innovations focus on efficient extraction of valuable metals like nickel, cobalt, lithium, and manganese from spent battery packs. This includes the development of innovative hydrometallurgical processes, which use chemical solutions to selectively dissolve the desired metals from the battery components, and pyrometallurgical methods, which utilize high temperatures to separate and refine the valuable materials. The crucial aspect is maximizing the recovery of these metals while minimizing environmental contamination.

Furthermore, research is actively pursuing the development of more sustainable and less energy-intensive processes. This includes exploring alternative chemical solutions, optimizing temperature control systems in pyrometallurgical processes, and implementing advanced separation techniques to increase the yield of valuable materials while reducing waste generation. These advancements are crucial for the economic viability and environmental sustainability of EV battery recycling.

Economic Benefits and Market Opportunities

The burgeoning EV battery recycling industry presents substantial economic opportunities for both established and emerging players. The increasing volume of spent EV batteries necessitates a robust recycling infrastructure, creating new jobs and markets for recycled materials. The recovery of valuable metals from these batteries can reduce reliance on imports, bolstering national security and fostering economic independence in various countries. The profitability of recycling operations hinges on the efficient extraction of valuable materials and the establishment of robust supply chains.

Infrastructure Development and Policy Support

The successful implementation of EV battery recycling hinges on the development of robust infrastructure and supportive policies. This includes the construction of specialized recycling plants equipped with advanced technologies to handle the processing of large volumes of spent batteries. The establishment of clear guidelines and regulations for battery disposal and recycling is essential to ensure ethical practices and environmental protection. Additionally, government incentives, such as tax breaks or subsidies for recycling facilities, can stimulate investment and drive the growth of this crucial industry. Policy support is vital in fostering a sustainable and profitable EV battery recycling sector.

Key Technologies Employed in EV Battery Recycling

Chemical Leaching

Chemical leaching is a crucial process in EV battery recycling, involving the use of specific chemicals to dissolve the valuable metals from the battery components. This method targets the extraction of lithium, nickel, cobalt, and manganese, which are vital components for producing new batteries. The process often involves carefully controlled chemical reactions and precise monitoring to ensure efficient extraction while minimizing environmental impact. This step is critical as it unlocks the valuable metals for further processing and allows for their recovery in a usable form. The process requires specialized equipment and skilled personnel to handle the potentially hazardous chemicals involved, ensuring safety and environmental responsibility.

Different chemical solutions are employed depending on the specific battery composition and the target metals. Careful selection of these reagents is essential to maximize metal recovery while minimizing the generation of hazardous byproducts. This step often involves multiple stages to optimize the extraction process and ensure complete removal of the target metals. Advanced techniques are continuously being developed to improve the efficiency and sustainability of chemical leaching, aiming at reducing the overall environmental footprint of this critical recycling stage.

Hydrometallurgical Processes

Hydrometallurgical processes play a significant role in the separation and purification of metals extracted during the chemical leaching stage. These processes leverage the different chemical properties of the extracted metals to selectively precipitate and recover them from the leach solutions. This step involves carefully controlling parameters like pH, temperature, and the addition of specific reagents to ensure optimal metal separation and minimize contamination. The use of hydrometallurgy is vital in achieving high-purity metal products suitable for use in the production of new batteries.

Various techniques like solvent extraction and precipitation are utilized within hydrometallurgical processes. Solvent extraction leverages the selective affinity of specific organic solvents to extract target metals from the leach solutions. Precipitation methods involve the controlled addition of reagents to induce the formation of solid metal compounds, facilitating their separation from the solution. These processes are crucial in achieving high-purity metal products, reducing impurities, and preparing the metals for the next steps in the recycling process.

Pyrometallurgical Methods

Pyrometallurgical methods, involving high temperatures, are employed in EV battery recycling to recover valuable metals, particularly those with high melting points. These methods often involve processes like smelting and roasting, which use heat to separate and refine metals. While pyrometallurgy can be effective in extracting certain metals, its environmental impact is a significant concern due to potential emissions of pollutants like greenhouse gases and heavy metal vapors. Consequently, environmental regulations and stringent emission control measures are crucial in mitigating these negative impacts.

Smelting, a common pyrometallurgical process, involves heating the battery components to high temperatures, causing the metals to melt and separate from other materials. Roasting, another pyrometallurgical process, involves heating the battery materials to a lower temperature, causing the desired metals to oxidize and be separated from the other components. These methods often require specialized furnaces and equipment to control the high temperatures and ensure efficient metal recovery.

Advanced pyrometallurgical techniques are being developed to reduce the environmental impact of these processes. These developments focus on improving the efficiency of metal extraction while reducing emissions and waste. The aim is to optimize the use of energy and resources while minimizing the production of harmful substances.

Challenges and Future Considerations

Adapting to Evolving Technologies

The rapid advancement of technology presents both exciting opportunities and significant challenges for businesses and individuals alike. Staying abreast of these changes is crucial for maintaining competitiveness and relevance in the market. Adapting to new software, platforms, and methodologies often requires significant investment in training and resources, which can be a barrier for smaller organizations or those with limited budgets. This dynamic environment necessitates continuous learning and a willingness to embrace innovation.

Furthermore, the integration of new technologies often requires restructuring workflows and processes. This can lead to initial disruptions and potential resistance from employees accustomed to established methods. Effective communication, clear training, and a supportive organizational culture are essential to navigate these transitions smoothly.

Addressing Ethical Considerations

As technology permeates every facet of modern life, it's essential to proactively address the ethical implications of its use. Ensuring data privacy and security is paramount in a world where personal information is increasingly digitized. Robust security measures and transparent data handling practices are critical to building trust and maintaining a positive public image. This includes careful consideration of potential biases in algorithms and the responsible use of artificial intelligence.

Another important ethical dimension is the potential for job displacement due to automation. Strategies that focus on reskilling and upskilling the workforce are needed to mitigate the negative impacts of these changes. Ethical considerations must be at the forefront of technological development and implementation.

Managing Resource Constraints

Financial resources and skilled personnel are often significant constraints to overcome in implementing new technologies and strategies. Obtaining funding for research and development or acquiring necessary equipment can be challenging, particularly for startups and smaller enterprises. Furthermore, finding qualified personnel with the technical expertise to manage and maintain complex systems can be difficult and expensive. This often necessitates strategic partnerships, outsourcing, or exploring innovative training programs.

This need for resources extends to the human element. Maintaining a motivated and productive workforce in a rapidly changing technological landscape requires ongoing investment in employee well-being, training, and development. This includes addressing concerns about job security, supporting employees in their transition to new roles, and fostering a culture of continuous learning.

Forecasting Future Trends

Accurately anticipating future technological trends is crucial for long-term planning and strategic decision-making. The pace of innovation is accelerating, making accurate predictions increasingly complex. Understanding emerging technologies, like AI, quantum computing, and the Internet of Things, is vital for anticipating their potential impact on various industries. This requires ongoing research and analysis of market data, technological advancements, and societal shifts.

The ability to adapt and capitalize on emerging opportunities while mitigating potential risks is crucial for organizations aiming to thrive in the future. Analyzing potential disruptions, such as shifts in consumer preferences, regulatory changes, and global economic trends, is equally important. This forward-thinking approach allows organizations to proactively position themselves for future success in an ever-evolving landscape.