What is a Driveshaft and What Does it Do?

What is a Driveshaft?

At the heart of every vehicle's drivetrain lies the driveshaft, an often overlooked but indispensable component. This rotating metal tube serves as the critical bridge between your engine's raw power and the wheels that propel you forward. Without this vital connection, even the mightiest engine would be useless for transportation. The driveshaft's job goes beyond simple rotation - it must accommodate the complex dance of suspension movement while maintaining perfect alignment.

The Driveshaft's Function in Power Transmission

Imagine your vehicle's power delivery as a relay race where the driveshaft is the star athlete. This component doesn't just carry power - it manages the violent twists and turns of torque delivery during acceleration while smoothing out the shocks from road imperfections. During hard braking, the driveshaft reverses its role, handling compression forces that would destroy lesser components. Its ability to maintain rotational integrity under these extreme conditions is nothing short of engineering brilliance.

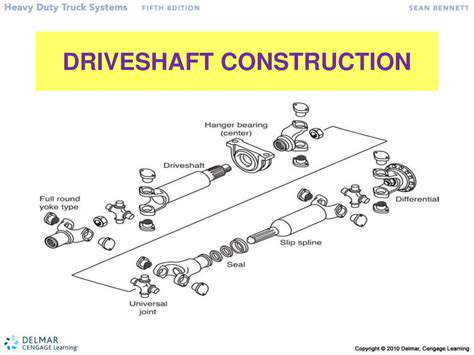

Driveshaft Design and Construction

Modern driveshafts represent a perfect marriage of metallurgy and precision engineering. Manufacturers typically use chrome-molybdenum steel alloys, carefully heat-treated to achieve the ideal balance between strength and flexibility. The hollow tube design isn't accidental - this configuration provides maximum strength with minimal weight, while the precisely calculated wall thickness ensures optimal resistance to torsional forces. Each driveshaft undergoes rigorous balancing tests, spinning at high speeds while lasers measure micron-level imperfections.

Different Types of Driveshafts

Driveshaft configurations vary as much as the vehicles they power. Front-wheel drive cars integrate the driveshaft into their transaxle assemblies, while heavy-duty trucks might use multiple-section shafts with carrier bearings. Performance vehicles often employ carbon fiber composites that reduce rotational mass, while off-road machines use heavy-duty versions with reinforced universal joints. The diversity in driveshaft technology mirrors the incredible variety of modern automotive applications.

Maintenance and Troubleshooting of a Driveshaft

Like any hard-working component, driveshafts demand regular attention. Mechanics recommend inspections every 30,000 miles, checking for telltale signs like grease leakage from U-joints or unusual vibrations at specific speeds. Ignoring a failing driveshaft can have catastrophic consequences - a broken shaft at highway speeds can literally pole-vault your vehicle. Proper maintenance includes periodic lubrication of U-joints and careful inspection of all mounting hardware for signs of fatigue or corrosion.

Types of Driveshaft Construction and Materials

Types of Rigid Driveshafts

Rigid driveshafts represent the brute force approach to power transmission, favored in applications where flexibility takes a backseat to raw strength. These single-piece steel behemoths excel in dump trucks and heavy machinery where torque requirements would snap more sophisticated designs. Their simplicity is their strength - no moving parts means fewer failure points under extreme loads. However, this rigidity demands perfect alignment, as even slight misalignment can cause destructive vibrations.

Flexible Driveshaft Design

The automotive world's answer to the rigid driveshaft's limitations comes in the form of flexible designs. These ingenious assemblies use precisely engineered universal joints to accommodate the constant motion between a vehicle's frame and suspension. This flexibility allows your rear wheels to move over bumps while maintaining perfect power delivery - a feat that would be impossible with rigid construction. The trade-off comes in increased complexity and maintenance requirements, but for most passenger vehicles, it's a small price to pay for smooth operation.

The Importance of U-Joints

Universal joints are the unsung heroes of drivetrain technology. These cross-shaped assemblies allow driveshafts to bend without breaking, transmitting power through angles that would stall lesser systems. A properly lubricated U-joint can outlast the vehicle itself, while a neglected one can fail spectacularly with little warning. Modern sealed-for-life joints have reduced maintenance needs, but purists still swear by the serviceable designs that allow for regular grease replenishment.

Hollow vs. Solid Driveshaft Construction

The hollow vs. solid driveshaft debate isn't about strength - it's about smart engineering. While solid shafts offer theoretical strength advantages, hollow designs actually provide better resistance to torsional forces thanks to physics principles. The hollow shaft's secret lies in distributing stress more evenly across its surface, while the removed material reduces rotational mass for better acceleration. Only in extreme applications like drag racing do solid shafts still find favor, where instantaneous torque transfer outweighs all other considerations.

The Role of Splines in Driveshaft Design

Splines transform a simple shaft into a precision power transmission device. These precisely machined grooves create a gear-like connection that can handle tremendous torque while allowing for necessary movement. The spline's genius lies in its ability to maintain perfect alignment while accommodating the slight length changes that occur during suspension travel. Modern CNC machining has brought spline manufacturing to new levels of precision, ensuring perfect fits that eliminate the slop which once plagued older vehicles.

The Benefits of Gear-Driven Driveshafts

For specialized applications requiring precise speed reduction, gear-driven shafts offer an elegant solution. These systems use helical cut gears to modify torque delivery characteristics while maintaining smooth operation. You'll find these in heavy equipment where massive torque multiplication is needed, or in precision machinery where exact speed control is critical. The trade-off comes in increased complexity and the need for specialized lubrication, but when the application demands it, nothing else will do.

Modern Driveshaft Technologies

The driveshaft's evolution continues at breakneck speed. Carbon fiber composites now offer strength comparable to steel at half the weight, while advanced lubrication technologies promise million-mile service intervals. Perhaps most exciting are active vibration damping systems that use sensors and counterweights to cancel out vibrations before they reach the cabin. As electric vehicles redefine automotive design, driveshaft technology adapts with innovative solutions for the unique demands of instant torque delivery.