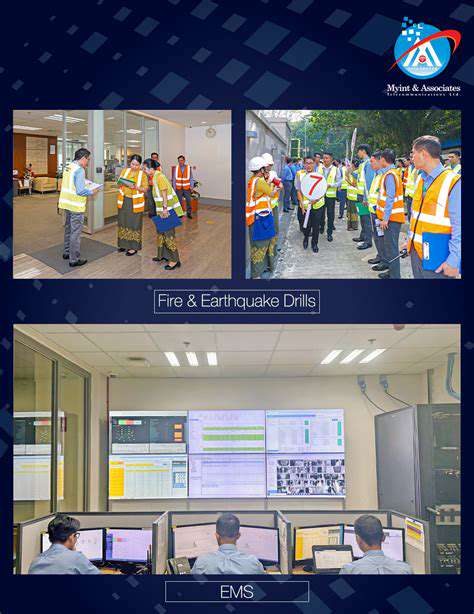

Ensuring Safety and Reliability

Prioritizing Safety Measures

Safety is paramount in any operation, and a robust safety culture is crucial for preventing accidents and ensuring the well-being of all personnel. Implementing and consistently enforcing safety protocols is essential for minimizing risks and maintaining a secure work environment. This involves regular safety training sessions, clear communication of safety procedures, and the provision of appropriate safety equipment. Continuous monitoring and evaluation of safety practices are vital to identify potential hazards and implement corrective actions promptly.

Furthermore, proactive risk assessment plays a significant role in anticipating potential dangers and mitigating their impact. Regular inspections of equipment and facilities, coupled with thorough hazard identification, contribute to a more secure environment. A proactive approach to safety not only prevents accidents but also fosters a culture of vigilance and responsibility among all personnel.

Maintaining Reliability Through Robust Systems

Reliability is critical for consistent performance and minimizing downtime. Establishing and maintaining robust systems is essential for ensuring dependable operation. This includes investing in high-quality equipment, performing regular maintenance, and implementing predictive maintenance strategies. These measures aim to anticipate potential failures and address them proactively.

Careful consideration should be given to the design and implementation of backup systems. Having redundant components or alternative processes in place can significantly improve reliability and ensure uninterrupted operation during unforeseen circumstances. Implementing a comprehensive system for tracking and analyzing equipment performance data can also help identify potential issues early and optimize maintenance schedules.

Implementing Quality Control Measures

Maintaining consistent quality is essential for meeting customer expectations and achieving operational efficiency. Rigorous quality control measures at every stage of the process help to minimize defects and ensure high standards. This includes implementing quality checks at critical points, establishing clear quality standards, and providing necessary training to personnel involved in the process. Consistent adherence to quality protocols is crucial in achieving optimal product or service quality.

In addition, implementing a system for collecting and analyzing quality data can offer valuable insights into areas needing improvement. Data-driven insights help identify trends and patterns, enabling proactive interventions to enhance quality standards. This approach helps to identify and address process bottlenecks or inefficiencies, ultimately improving overall quality and productivity.

Continuous Improvement and Learning

Continuous improvement is a key element in ensuring safety and reliability. A culture of continuous learning and improvement is essential for adapting to changing circumstances and enhancing operational efficiency. Regularly reviewing procedures, processes, and equipment, along with soliciting feedback from all stakeholders, is critical for identifying areas needing improvement. This iterative approach allows for the constant adaptation of processes and strategies to maintain optimal performance.

Implementing a system for tracking and analyzing performance data is vital for identifying trends and areas for improvement. This data-driven approach allows for the identification of potential issues early, enabling timely interventions and preventing larger problems. Regular reviews and audits are essential to ensure processes and procedures remain effective and aligned with evolving needs.

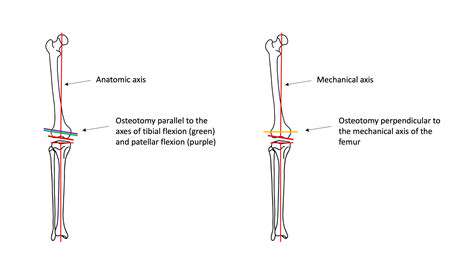

Beyond the Mechanical: Alignment in Other Domains

Beyond the Mechanical: Understanding Alignment

Alignment, in its broadest sense, encompasses the coordination and harmonious integration of various elements within a system. It's more than just a physical arrangement; it delves into the underlying principles and motivations that drive those elements towards a common goal. This concept is crucial in numerous fields, from engineering and design to organizational structure and even philosophical inquiry.

Understanding alignment requires a deep dive into the interconnectedness of components. It's not just about putting things next to each other, but about ensuring they work together effectively and efficiently. This necessitates a clear understanding of the objectives, constraints, and potential conflicts that might arise.

The Importance of Shared Vision

A shared vision is paramount to achieving effective alignment. When individuals and teams have a common understanding of the desired outcome, they are more likely to collaborate effectively and work towards a unified goal. This shared understanding fosters a sense of purpose and commitment, driving collective action towards achieving a common objective.

Without a clear and compelling vision, alignment becomes elusive, leading to confusion and disjointed efforts. A well-defined vision serves as a guiding star, illuminating the path towards a common destination.

The Role of Communication and Feedback

Open and transparent communication channels are essential for maintaining alignment. Regular feedback loops allow for the identification and resolution of potential misalignments, ensuring that everyone is on the same page and working towards a common goal. Without effective communication, misunderstandings and conflicts can arise, hindering progress and eroding trust.

Addressing Conflicts and Misalignments

Identifying and resolving conflicts is a critical aspect of maintaining alignment. Conflicts can arise from differing perspectives, priorities, or even conflicting objectives. A proactive approach to conflict resolution is essential to mitigate potential disruptions and maintain a cohesive and productive environment.

Addressing misalignments early on is crucial for avoiding larger-scale problems. This involves implementing strategies for identifying and resolving discrepancies in a timely and effective manner.

Systemic Alignment: Interconnectedness and Synergy

Aligning systems involves recognizing the interconnectedness of various components. A change in one part of the system can have ripple effects throughout, necessitating a holistic approach to ensure that all elements are working harmoniously. This systemic view allows for the optimization of the entire system, rather than simply addressing individual components in isolation.

Practical Application in Various Domains

The principles of alignment apply to a wide range of domains, including project management, organizational development, and even personal development. Understanding and applying these principles can lead to significant improvements in efficiency, productivity, and overall effectiveness in any endeavor. Ultimately, alignment is about harnessing the collective power of a group or system towards a common goal.

By integrating alignment strategies into our daily interactions, we can create more cohesive, efficient, and ultimately successful outcomes.