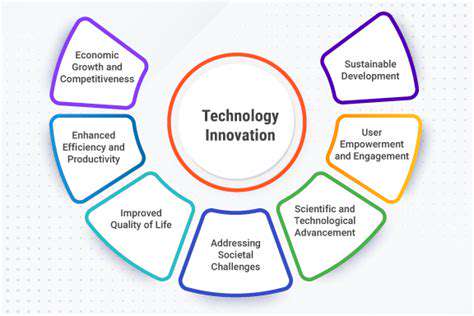

Businesses worldwide are transforming their strategies to align with modern environmental expectations. Consumers and investors now demand accountability, pushing companies to integrate eco-friendly measures into daily operations. The choice to adopt sustainability has evolved from optional to imperative for enduring success. Organizations embracing these values not only attract top talent but also build stronger brand reputations while supporting global ecological health.

From cutting carbon footprints to ethical supply chains, sustainable initiatives drive innovation while reducing costs. Forward-thinking firms discover new markets by creating green products that appeal to environmentally conscious buyers. This dual focus on planet and profit reshapes industries while securing competitive advantages. The ripple effects extend beyond immediate financial gains, fostering long-term customer loyalty and industry leadership.

The Impact of Sustainable Practices on Profitability and Brand Image

Operational efficiencies from sustainability measures directly enhance financial performance. Energy-efficient facilities slash utility expenses, while optimized waste systems minimize disposal fees. Ethical sourcing practices simultaneously improve product quality and supplier relationships, creating multilayered value throughout the supply chain.

Modern consumers actively evaluate corporate environmental responsibility when making purchases. Companies demonstrating genuine commitment to sustainability enjoy greater customer retention and organic advocacy. This goodwill translates into measurable market differentiation that outlasts temporary marketing campaigns. The resulting brand equity becomes an intangible asset that competitors struggle to replicate.

Investment communities now prioritize ESG metrics, channeling capital toward businesses with sustainable visions. This financial endorsement enables further innovation while validating the economic viability of environmental stewardship. The convergence of ecological and financial interests creates a powerful catalyst for systemic change across industries.

Current Battery Recycling Technologies: A Diverse Landscape

Chemical Extraction Methods

Specialized chemical processes recover precious metals like lithium and cobalt from depleted batteries. While effective, these methods require meticulous waste management to prevent environmental contamination. The industry continually refines these techniques to balance metal recovery rates with ecological safety.

Hydrometallurgical Processes

This water-based extraction approach offers cleaner metal separation compared to high-temperature alternatives. Precise control of acidic solutions enables efficient material recovery while reducing hazardous byproducts. Technological advancements continue improving the selectivity and environmental profile of these processes.

Pyrometallurgical Techniques

High-temperature smelting remains prevalent despite its substantial energy requirements. Modern facilities incorporate emission control systems to mitigate environmental impact while maintaining metal purity standards. The industry explores hybrid approaches combining thermal and chemical methods for optimal efficiency.

Mechanical Separation Techniques

Initial battery disassembly relies on sophisticated sorting technologies that categorize materials before chemical processing. Automated systems now achieve remarkable precision in separating casings, electrodes, and other components. This preprocessing stage significantly enhances downstream recovery efficiency.

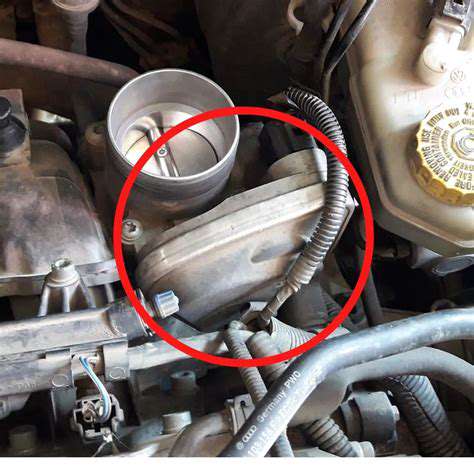

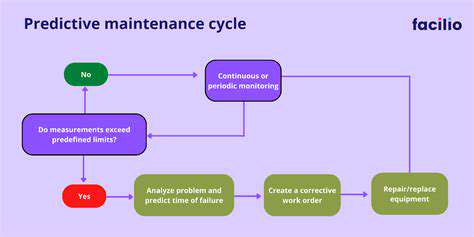

Advanced Materials Characterization and Analysis

Cutting-edge analytical instruments provide granular insights into battery composition. These diagnostics inform customized recycling protocols for different battery chemistries, maximizing resource recovery while minimizing waste. Such precision engineering represents the future of sustainable material reclamation.

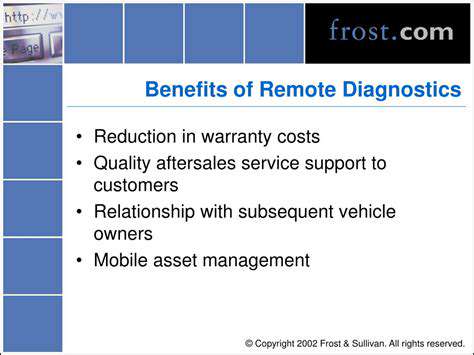

Economic and Regulatory Aspects of Recycling

Market dynamics and policy frameworks profoundly influence recycling viability. Progressive legislation creates financial incentives for closed-loop systems, while commodity prices dictate operational priorities. The intersection of environmental policy and market economics will determine the pace of industry maturation.

The Future of EV Battery Recycling: A Collaborative Approach

Driving the Transition to Sustainable Battery Recycling

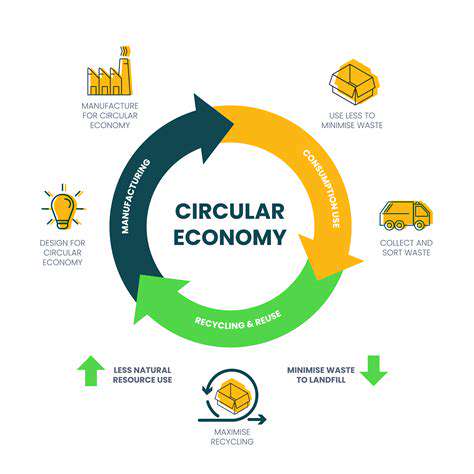

The EV revolution demands comprehensive recycling solutions that address the entire product lifecycle. Manufacturers, recyclers, and policymakers must synchronize efforts to build efficient material recovery networks. This systemic approach transforms waste management into resource regeneration, ensuring electric vehicles fulfill their environmental promise.

Standardized collection systems and modular battery designs facilitate easier material recovery. Emerging business models promote battery refurbishment alongside traditional recycling, creating multiple value streams. The industry moves beyond simple disposal toward sophisticated material stewardship.

Optimizing Recycling Technologies for Maximum Material Recovery

Next-generation separation techniques achieve unprecedented purity levels in reclaimed materials. Solvent innovations and electrochemical processes reduce energy consumption while improving yields. These technological leaps make recycled materials competitive with virgin resources, closing the loop on battery production.

Cross-disciplinary research accelerates breakthroughs in material science and process engineering. Pilot facilities test innovative approaches at commercial scales, bridging the gap between laboratory discoveries and industrial implementation. The continuous improvement cycle drives down costs while raising environmental standards.

Policy and Infrastructure: Enabling Sustainable Recycling Practices

Governments implement extended producer responsibility schemes that incentivize eco-design. Strategic investments in regional recycling hubs create efficient material flows. Regulatory frameworks establish clear performance standards while encouraging technological innovation through targeted subsidies.

Public education campaigns demystify battery recycling for consumers. Convenient drop-off locations and transparent tracking systems build trust in the recycling process. This grassroots engagement complements top-down policy measures to create a comprehensive solution.

The Economic Incentives for a Circular EV Battery Economy

Material recovery reduces manufacturing costs by up to 30% for some battery components. This cost advantage makes EVs more accessible while insulating manufacturers from commodity price volatility. The circular economy model generates local employment across collection, processing, and remanufacturing sectors, creating economic resilience alongside environmental benefits.

Secondary markets for refurbished batteries and recovered materials create new revenue streams. Financial institutions develop specialized investment products to fund recycling infrastructure, recognizing its long-term value proposition. The economic case for battery recycling strengthens as technologies mature and scales increase.