Low-VOC paint systems serve as a stepping stone toward completely VOC-free solutions. These formulas contain fewer volatile compounds than standard paints, alleviating some environmental issues tied to high-VOC products. Producers typically seek equilibrium between lowered emissions and maintaining paint performance standards.

For many car makers, implementing low-VOC paints represents a more feasible sustainability measure. This approach enables gradual adoption of eco-friendlier methods while preserving crucial coating performance needs.

Technological Advancements in VOC Reduction

Breakthroughs in paint chemistry and formulation methods have dramatically cut VOC content in automotive coatings. Innovations like alternative solvents, novel binding agents, and enhanced curing techniques contribute to developing more sustainable, effective paint systems. These advances prove indispensable for creating durable, high-quality vehicle finishes with minimal ecological impact.

Scientists and industry experts continually investigate new materials and processes to further decrease paint emissions. This persistent research fuels innovation and drives progress toward increasingly sustainable coating solutions.

Sustainable Practices and Regulations

Environmental regulations increasingly shape automotive industry practices regarding VOC emissions. Strict policies push manufacturers toward sustainability, including adoption of low-VOC and VOC-free paint systems. These rules stimulate innovation and promote eco-conscious solutions.

Implementing sustainable paint technologies extends beyond regulatory compliance. It boosts corporate image, attracts environmentally-aware customers, and may yield long-term cost savings. By proactively addressing ecological concerns, the auto industry can establish itself as a leader in responsible manufacturing.

The Role of Bio-Based and Recycled Materials

Bio-Based Materials: A Sustainable Alternative

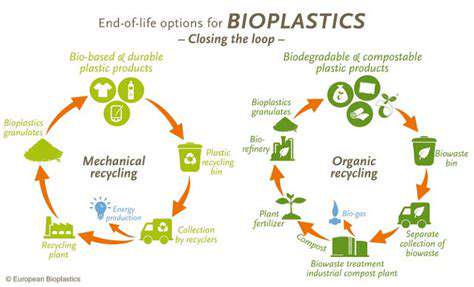

Derived from renewable sources like plants and farm waste, bio-based materials provide an eco-friendly substitute for petroleum-based products. They play a pivotal role in reducing humanity's environmental footprint. These innovative materials pave the way for circular economies, lessening dependence on finite resources and lowering greenhouse emissions. Typically, producing bio-based materials requires less energy than manufacturing fossil fuel alternatives, further enhancing sustainability.

The adaptability of plant-derived materials is impressive. They're being utilized across multiple sectors - from packaging and construction to textiles and bioplastics - making them invaluable assets for sustainable development. Continuous innovation promises even greater environmental benefits in coming years.

Recycled Materials: Extending the Lifespan of Existing Resources

Recycled materials are fundamental for waste reduction and resource conservation. By repurposing discarded items, we dramatically decrease demand for virgin materials, protecting natural resources. Recycling stands as a foundation of sustainable practices, offering an ecologically sound waste management solution that reduces manufacturing's environmental burden.

Recycling methods vary by material type, typically involving sorting, cleaning, and reprocessing into new products. These processes may be mechanical or chemical, depending on the material. Their efficiency directly impacts recycling's environmental benefits. Successful recycling requires cooperation between individuals, communities, and industries.

The Environmental Impact of Traditional Materials

Conventional materials, primarily sourced from fossil fuels, carry substantial ecological consequences. Their production consumes significant energy, generating greenhouse gases that accelerate climate change. Extraction and processing frequently damage ecosystems through habitat destruction and water contamination.

The durability and widespread use of traditional materials create massive waste streams. Proper disposal is crucial for mitigating environmental harm. Unfortunately, much ends up in landfills, threatening both environmental and human health. The urgency for sustainable alternatives grows daily.

The Economic Benefits of Sustainable Materials

Shifting toward bio-based and recycled materials presents substantial economic opportunities. New industries and jobs will emerge around developing, producing, and processing these materials. Investment in this sector can drive economic expansion while advancing environmental goals.

Reduced dependence on imported raw materials strengthens national economic security. Sustainable materials may also yield long-term cost savings by decreasing reliance on expensive, finite resources. The comprehensive economic advantages of sustainable practices are both significant and wide-ranging.

The Future of Materials: Innovation and Collaboration

Material science progress depends on ongoing innovation and cooperation among researchers, manufacturers, and consumers. This partnership is essential for developing superior sustainable materials, enhancing recycling technologies, and encouraging responsible consumption. Through collective effort, we can achieve truly environmentally responsible and economically feasible material production.

Continuous research promises even more sustainable options ahead. The potential for groundbreaking advancements in coming years is extraordinary.

Advanced Coating Technologies for Enhanced Durability and Performance

Advanced Materials for Enhanced Durability

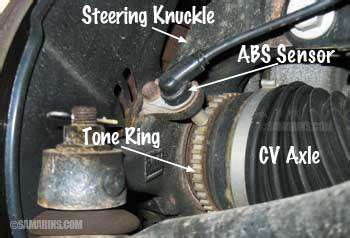

Protective coatings significantly extend material lifespans and improve performance across applications from auto parts to medical devices. Cutting-edge materials are increasingly integrated into coatings to achieve exceptional durability, corrosion resistance, and wear protection. This enables creation of coatings capable of enduring extreme conditions and rigorous use.

Developing novel materials with distinctive properties - like extreme hardness and chemical resistance - is fundamental for these advancements. When incorporated into coatings, these materials dramatically boost component performance.

Surface Modification Techniques

Surface modification methods are crucial for high-performance coatings. These techniques customize surface properties for specific applications. Plasma-enhanced chemical vapor deposition (PECVD) excels at depositing ultra-thin films with precisely controlled composition and structure, enabling optimal coating performance.

Atomic layer deposition (ALD) creates exceptionally uniform, conformal coatings. ALD proves especially valuable when precise thickness control and premium coating quality are essential.

Advanced Coating Processes

Innovative coating processes improve application efficiency and effectiveness. Specialized methods like high-velocity oxygen fuel (HVOF) spraying deposit dense, high-performance coatings on complex shapes.

This technique substantially reduces defects and enhances final product quality. Other advanced processes include thermal spraying, offering versatile application options for metals and ceramics alike.

Coatings for Enhanced Functionality

Beyond basic protection, modern coatings deliver added functionality. Self-healing varieties automatically repair damage, prolonging component life. These innovative coatings contain micro-capsules that release healing agents when damaged, restoring original properties.

Advanced Coating Applications in Industries

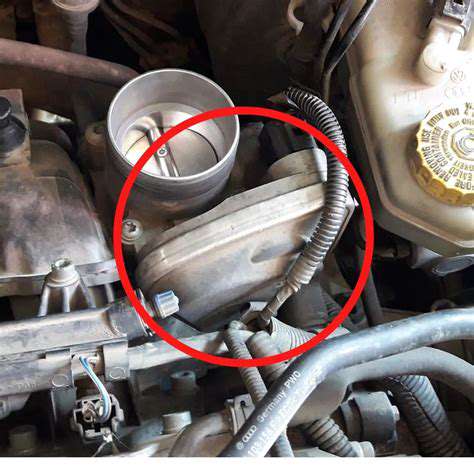

Advanced coating applications are expanding rapidly across sectors. Aerospace relies on these coatings to boost aircraft component performance under extreme temperatures, stress, and corrosion. Similarly, automotive coatings enhance vehicle aesthetics while preventing rust, corrosion, and wear.

Cost-Effectiveness and Sustainability

Advanced coating development must balance performance with affordability and sustainability. Research focuses on economical, eco-friendly materials and processes that minimize waste and hazardous substances. Practical, sustainable coating solutions are critical for long-term market success.

Incorporating recycled materials into coatings can further improve sustainability and reduce ecological impact.

Future Trends and Research Directions

Future coating research will likely concentrate on sophisticated multifunctional varieties offering not just protection but also features like self-cleaning, sensing capability, and energy efficiency. Potential applications are vast and will transform multiple industries.

Continued investigation of new materials and processes, combined with improved application techniques, will drive further innovation in this dynamic field.