Introduction to Life Cycle Assessment in the Automotive Industry

Understanding the Scope of LCA in Automotive

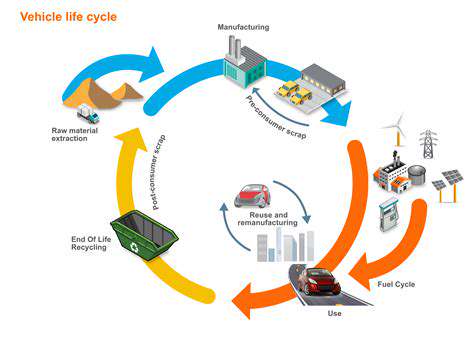

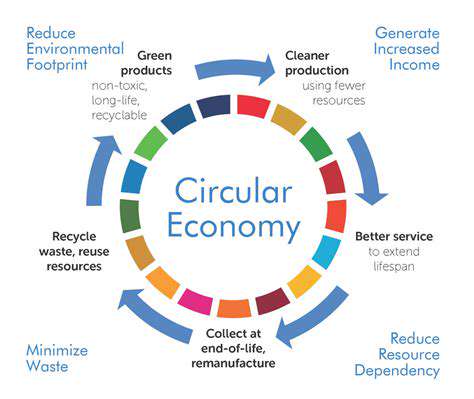

When examining Life Cycle Assessment (LCA) within automotive applications, we must consider the complete environmental footprint generated by a vehicle from conception to retirement. This goes beyond just fuel consumption during operation - it involves scrutinizing every phase including material sourcing, component fabrication, assembly logistics, operational lifespan, and final recycling or scrapping procedures. The interconnectivity of these elements forms a complex web that determines the true ecological price of automotive products.

What many don't realize is that the environmental implications begin long before a vehicle rolls off the assembly line. The extraction of ores for metal components, petroleum for plastics, and rare earth elements for electronics each carry distinct ecological consequences. Only by mapping this complete pathway can manufacturers identify the most effective intervention points for reducing environmental harm across their product lines and supply networks.

Key Stages in Conducting an LCA

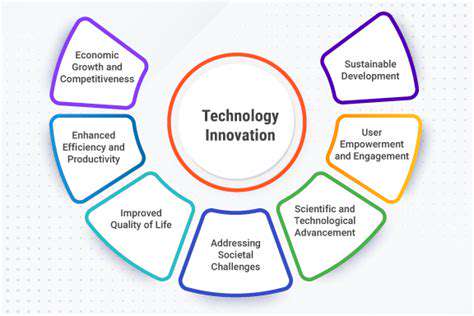

Implementing a thorough LCA requires methodical execution across several critical phases. First comes the crucial definition phase where analysts establish clear boundaries for what will be measured - will the study focus on carbon emissions alone, or include water usage, toxic releases, and other factors? Next comes the intensive data gathering process, tracking every watt of energy and kilogram of material that flows through the production system.

The interpretation phase often yields surprising revelations, as environmental impacts frequently emerge from unexpected corners of the supply chain. Companies routinely discover that seemingly minor components or processes contribute disproportionately to the overall footprint, allowing for targeted improvements with maximum environmental benefit.

Material Selection and its Environmental Impact

Modern vehicles incorporate hundreds of different materials, each with unique environmental profiles. Aluminum might save weight and improve fuel efficiency during operation, but its production requires tremendous energy inputs. Advanced composites offer strength advantages but may prove difficult to recycle. The LCA process quantifies these tradeoffs, enabling engineers to make informed decisions that balance performance, cost, and sustainability.

Emerging material technologies present both opportunities and challenges for lifecycle analysis. Bio-based plastics, for instance, might reduce petroleum dependence but require careful assessment of agricultural impacts. Recycled content materials often show excellent environmental performance, provided the collection and processing infrastructure exists to support them at scale.

Environmental Impacts of Manufacturing Processes

Automotive factories represent complex ecosystems of material and energy flows. The painting process alone can account for a significant portion of a plant's volatile organic compound emissions, while metal stamping operations consume vast amounts of electricity. Advanced LCA techniques now allow manufacturers to model different production scenarios, comparing the impacts of alternative processes before making capital investments.

Water usage represents another critical manufacturing consideration, particularly in water-stressed regions. Cutting-edge facilities now implement closed-loop water systems that dramatically reduce consumption, while new surface treatment technologies eliminate hazardous wastewater streams entirely.

LCA and Sustainable Design in the Automotive Industry

The most effective sustainability strategies begin at the drawing board. Forward-thinking automakers now employ LCA data during initial design phases, using it to guide decisions about material specifications, joining methods, and even product architectures. This proactive approach prevents environmental liabilities from being designed into vehicles in the first place, rather than attempting costly mitigation later in the product lifecycle.

Looking ahead, LCA will play an increasingly vital role as the industry transitions to electric vehicles. While EVs eliminate tailpipe emissions, their battery systems introduce new environmental considerations around mineral extraction, manufacturing energy use, and end-of-life management that require careful lifecycle analysis.