Pre-processing and Disassembly: The Foundation of Battery Recycling

Pre-processing: Preparing Batteries for Recycling

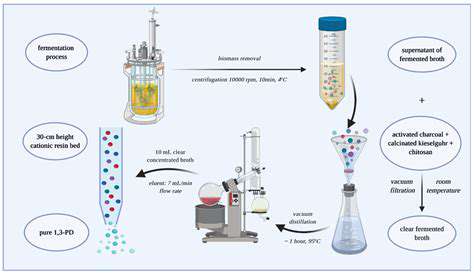

The first stage in EV battery recycling involves thorough pre-processing, which establishes the groundwork for effective material recovery. This crucial phase includes several important steps, such as removing non-battery elements including the battery management system (BMS), wiring, and other attached components. Proper separation at this stage prevents contamination of valuable battery materials and ensures correct sorting during later processes. Maintaining detailed records of each procedure helps track progress and optimize material recovery.

Additionally, pre-processing typically involves cleaning and organizing battery components before disassembly. Workers may need to remove leftover chemicals or contaminants from battery modules or individual cells, creating clean conditions for subsequent steps. Sorting methods, which might combine visual checks with automated systems, help categorize various battery parts to improve the efficiency of later stages. This careful preparation not only boosts overall process efficiency but also protects worker safety throughout the recycling operation.

Disassembly: Breaking Down Battery Components

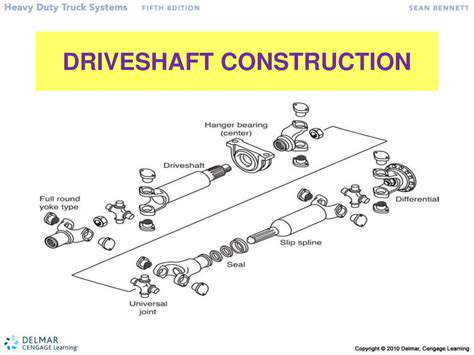

Disassembly represents a critical phase where technicians carefully separate battery packs into their individual components. This process involves isolating battery modules, cells, and other parts to prepare them for further processing. The specific techniques used vary depending on battery design and desired recovery outcomes. Specialists must select appropriate tools and equipment to prevent damage to components while ensuring operator safety.

Effective disassembly significantly reduces material loss and enables successful recovery of important metals such as nickel, cobalt, and manganese. Modern facilities often use advanced equipment like robotic arms and precision cutting tools to perform these tasks safely and efficiently. The accurate separation of different materials – including plastics, metals, and electrolytes – proves essential for targeted recovery and subsequent processing stages.

Quality Assurance and Sustainability: Key Considerations

Ensuring Battery Quality During Production

Maintaining high standards in EV battery production directly impacts their long-term reliability and safety. Manufacturers implement strict quality control protocols throughout the entire manufacturing process, from material procurement to final assembly. These measures include detailed testing at multiple stages, such as component purity verification and comprehensive performance evaluations for capacity, voltage, and lifespan. Early detection of potential issues through these tests helps prevent operational failures and enhances overall battery system dependability.

In addition to standard testing, producers increasingly utilize advanced simulations and predictive models to identify possible weaknesses and refine battery designs. This forward-thinking strategy enables manufacturers to resolve potential problems before they affect field performance. The comprehensive quality assurance approach aims to produce batteries that surpass industry benchmarks for performance, safety, and durability.

Addressing Environmental Concerns in Battery Manufacturing

While essential for sustainable transportation, EV battery production carries environmental implications that require careful management. Reducing this impact demands a holistic approach covering the entire battery lifecycle, from material extraction to final disposal. Responsible sourcing of critical materials like lithium, cobalt, and nickel helps minimize ecological damage from mining operations. Equally important are programs for recycling and repurposing battery components after their vehicular service life.

Manufacturers continue to investigate alternative battery chemistries and production methods to lessen environmental effects. These innovations include developing less resource-dependent materials and more efficient manufacturing processes. Implementing closed-loop systems where materials get recovered and reused represents a crucial step toward reducing the environmental footprint of EV battery production.

The ongoing refinement of eco-friendly production techniques, combined with rigorous waste management practices, plays a vital role in mitigating the environmental consequences of battery manufacturing. This dedication to sustainability ensures that the shift to electric vehicles truly benefits the environment, paving the way for cleaner transportation solutions.