Harnessing Solar Power for Energy Independence

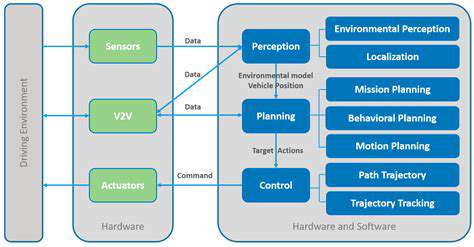

Solar Power Integration in Automotive Systems

Solar energy adoption is transforming the automotive industry's approach to sustainability. By incorporating photovoltaic technology into vehicles, manufacturers are creating new possibilities for reducing fossil fuel dependence. This shift requires balancing technical considerations like energy capture efficiency with consumer preferences regarding vehicle aesthetics and performance.

Public transportation systems stand to gain particularly from this innovation. Solar-assisted buses and commercial fleets could dramatically lower urban pollution levels while maintaining operational reliability. Continued technological refinements will determine how quickly these solutions become mainstream.

Challenges and Opportunities in Solar-Powered Vehicles

The road to widespread solar vehicle adoption isn't without obstacles. Current solar cell limitations mean substantial surface areas are needed to generate meaningful power, which impacts vehicle design flexibility. Weather-dependent energy production also demands sophisticated battery systems to ensure consistent performance.

Yet the potential rewards justify the effort. Breakthroughs in thin-film solar technology and lithium-ion batteries are gradually overcoming these barriers. Consumer interest in eco-friendly transportation options continues growing, creating market momentum for solar vehicle development.

Remote communities could benefit immensely from solar vehicle technology, reducing their need for extensive charging infrastructure. This decentralized energy approach enhances transportation resilience while supporting environmental goals.

Creative engineering solutions are emerging to address spatial constraints. Lightweight composite materials and strategic panel placement allow for more efficient energy capture without compromising vehicle functionality.

The environmental advantages of solar-powered transportation are clear. Overcoming current technical limitations through sustained research will determine how quickly these vehicles transform our roads.

Policy support and public education initiatives will accelerate adoption rates, helping solar vehicles transition from niche products to mainstream transportation solutions.

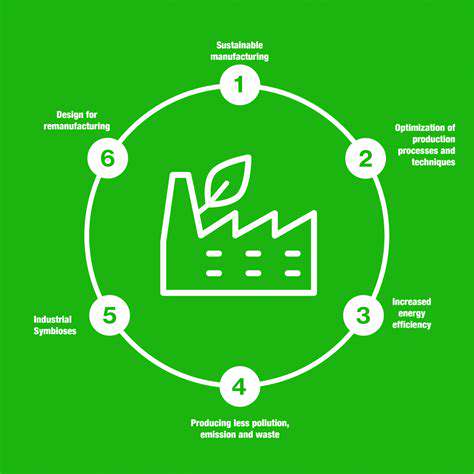

Optimizing Energy Efficiency in Production Processes

Improving Energy Efficiency in Manufacturing

Modern manufacturing operations increasingly prioritize energy conservation as both an economic and environmental imperative. Comprehensive energy audits can identify waste patterns, leading to targeted improvements in heating, cooling, and production line configurations. Smart sensors and automated control systems now enable precise energy management throughout facilities.

Proactive energy strategies create multiple benefits, from lower operating expenses to enhanced corporate sustainability profiles. These measures also foster operational cultures where efficiency becomes an ongoing priority rather than an afterthought.

Adopting Renewable Energy Sources

Forward-thinking manufacturers are integrating clean energy solutions directly into their operations. Rooftop solar arrays and small-scale wind turbines allow facilities to supplement grid power while stabilizing long-term energy costs. These distributed generation systems also provide energy security during grid disruptions.

Implementing Energy-Efficient Machinery

Equipment upgrades represent one of the most effective ways to reduce industrial energy consumption. Modern industrial motors, for instance, can achieve efficiency ratings above 90%, compared to 60-70% for older models. The payback period for such investments often surprises skeptics, with many upgrades recouping costs within 2-3 years through energy savings alone.

Comprehensive lifecycle analyses help identify the most impactful upgrades. These evaluations should account for regional energy prices, available incentives, and projected maintenance requirements to ensure sound financial decisions.

Process Optimization and Waste Reduction

Lean manufacturing principles directly contribute to energy conservation. Value stream mapping can reveal hidden inefficiencies in material flows and production sequences. Simultaneously, closed-loop recycling systems minimize both material waste and the energy embedded in wasted resources.

Employee Training and Awareness

Workforce engagement transforms energy initiatives from management directives into shared responsibilities. Practical training programs that demonstrate how individual actions affect facility-wide energy use create meaningful behavioral changes. Recognition programs for energy-saving suggestions further reinforce this cultural shift.

Sustainable Design and Product Lifecycle

Energy-conscious design principles are reshaping product development. Engineers now evaluate energy impacts across entire product lifecycles, from material extraction to end-of-life processing. Modular designs that facilitate repairs and upgrades extend product usefulness while reducing replacement energy costs.