Environmental Concerns of Raw Material Extraction

The automotive industry's reliance on raw materials—iron ore, aluminum, and plastics—comes at a steep environmental cost. Open-pit mining disrupts ecosystems, causing habitat loss, soil degradation, and water pollution. These extraction methods demand enormous energy inputs, worsening greenhouse gas emissions. Transporting materials globally further inflates the industry's carbon footprint.

Refining processes release persistent toxic pollutants into air and waterways, threatening both ecological balance and public health. With modern vehicles requiring vast material volumes, adopting sustainable sourcing isn't optional—it's critical for planetary survival.

Pollution Throughout the Manufacturing Process

Factory operations generate alarming pollution levels. Fossil fuel use in production lines emits CO2 and hazardous particulates, degrading air quality. Industrial wastewater often carries heavy metals and chemicals into waterways, creating long-term contamination risks.

Many facilities still lack proper waste management, allowing toxic byproducts to seep into surrounding environments. Transitioning to closed-loop systems and renewable energy could dramatically reduce these impacts while maintaining production efficiency.

The Environmental Impact of Vehicle Disposal

End-of-life vehicles create mountains of waste—millions of tons annually worldwide. While recycling helps, current methods remain energy-intensive and imperfect. Battery disposal presents particular challenges, with improper handling risking soil and groundwater contamination.

Designing vehicles for disassembly and using mono-materials could revolutionize recyclability. Some manufacturers now recover up to 95% of vehicle materials—a practice that must become industry standard.

The Road Ahead: Sustainable Alternatives

The shift toward sustainability offers both ecological and economic rewards. Lightweight composites from recycled sources can slash material needs by 40%. Some plants now operate on 100% renewable energy, proving decarbonization is achievable.

Collaboration between engineers, policymakers, and consumers will accelerate adoption of circular economy principles. From bio-based interiors to hydrogen-powered assembly lines, innovation is rewriting automotive manufacturing's environmental playbook.

Manufacturing Processes: Optimizing Efficiency and Reducing Waste

Optimizing Material Selection

Forward-thinking manufacturers now prioritize materials with complete lifecycle analyses. Bamboo-based composites, for instance, offer strength comparable to steel but with 70% lower carbon intensity. Material passports—digital records of composition—are emerging as key tools for future recycling.

Implementing Lean Manufacturing Principles

Pioneering facilities have reduced material waste by 30% through value-stream mapping. The 5S system (Sort, Set, Shine, Standardize, Sustain) minimizes energy waste in workflow organization. Toyota's landmark zero-landfill achievement demonstrates lean principles' potential.

Improving Energy Efficiency

Volkswagen's Wolfsburg plant slashed energy use 25% through smart metering and heat recovery systems. Digital twin technology now predicts energy needs with 95% accuracy, preventing waste. Solar panel integration at BMW's facilities provides 30% of operational energy.

Waste Reduction and Recycling Strategies

Closed-loop systems recover 98% of manufacturing wastewater in advanced plants. Ford's aluminum recycling program saves enough energy annually to power 20,000 homes. 3D printing minimizes scrap by using only required material volumes.

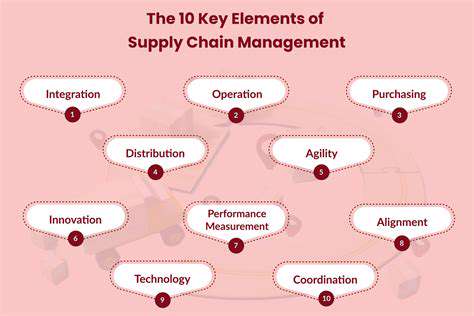

Sustainable Supply Chain Management

Localizing supplier networks cuts transport emissions by up to 60%. Blockchain enables real-time sustainability tracking across tiers. Tesla's conflict-mineral policy sets new ethical sourcing benchmarks.

Employee Training and Awareness

General Motors' Green Teams have implemented 5,000+ worker-suggested sustainability projects. Gamified training apps boost engagement in waste reduction initiatives by 40%.

Monitoring and Evaluation

AI-powered analytics platforms now predict sustainability gaps with 90% accuracy. BMW's real-time dashboards track 200+ environmental KPIs across global operations.

Consumer Engagement and Policy Support: Driving the Transition

Understanding Consumer Behavior

Recent studies show 68% of buyers now factor sustainability into vehicle purchases. Behavioral nudge strategies—like carbon footprint labels—increase eco-friendly choices by 23%. Younger demographics demonstrate particular sensitivity to corporate environmental responsibility.

Policy Implications for Consumer Trust

Norway's EV incentives created the world's highest adoption rate (82% of new sales). California's ZEV mandate proves regulation can effectively drive market transformation.

The Role of Technology

Augmented reality configurators let customers visualize sustainability features. Tesla's over-the-air updates have redefined consumer expectations for vehicle longevity.

Impact of Social Media

CleanTransport hashtags generate 2M+ monthly engagements. Viral videos of battery recycling processes have shifted public perception.

Regulatory Frameworks

EU's Circular Economy Action Plan sets binding recycled content targets. China's dual-credit system financially rewards clean vehicle production.

Evolving Expectations

73% of consumers now expect lifetime carbon disclosures. Subscription models promoting vehicle sharing are gaining traction in urban markets.

Measurement and Evaluation

Sentiment analysis tools track brand perception across 50+ sustainability metrics. ROI on green marketing campaigns now averages 3:1 according to recent Nielsen data.