Exploring Advanced Materials

Modern automotive wiring demands go far beyond traditional copper solutions, pushing engineers toward materials offering superior performance and functionality. This shift requires expertise in material science, focusing on conductivity, durability, and weight reduction. Cutting-edge materials like graphene and carbon nanotubes show particular promise for high-efficiency applications where conventional metals fall short.

Industry researchers constantly evaluate novel composite materials that could transform multiple sectors. These innovations aim to address critical needs for lighter components that maintain strength while improving energy efficiency in vehicles.

High-Performance Composites

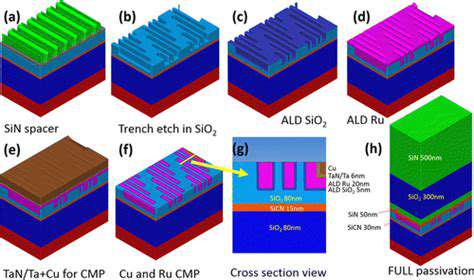

Today's advanced composites blend polymers, ceramics, and metals to achieve unprecedented strength-to-weight characteristics. In the automotive sector, these materials directly impact fuel economy by reducing vehicle mass while maintaining structural integrity. Engineers meticulously formulate these materials to meet specific performance benchmarks.

Manufacturing techniques continue evolving to handle these sophisticated materials. Potential applications range from structural elements to thermal management systems, demonstrating their versatility across multiple vehicle systems.

Advanced Ceramics for Extreme Conditions

Modern ceramics withstand extreme environments better than most metals, offering superior heat resistance and durability. These properties make them ideal for high-stress automotive applications where traditional materials would fail.

From high-performance brake systems to exhaust components, advanced ceramics enable critical functions under punishing conditions. Their unique characteristics continue finding new applications throughout vehicle design.

Bio-Inspired Sustainable Solutions

Nature's designs inspire revolutionary materials that combine performance with environmental responsibility. By mimicking biological structures, researchers develop solutions that outperform conventional options while reducing ecological impact.

This biomimicry approach leads to innovative materials for energy systems, structural components, and even self-healing coatings. The automotive industry increasingly adopts these solutions to meet sustainability goals without compromising performance.

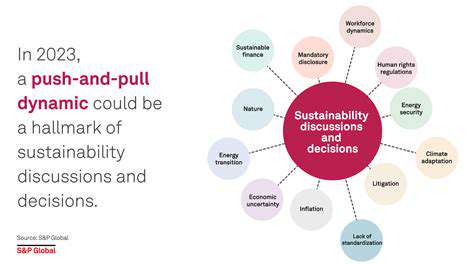

Eco-Conscious Manufacturing

Responsible material production requires sustainable manufacturing processes that minimize environmental harm. Energy-efficient production methods and waste reduction strategies have become essential considerations.

Green manufacturing practices demonstrate that technological progress need not come at the planet's expense. These methods help balance industrial development with environmental stewardship, creating a model for future innovation.

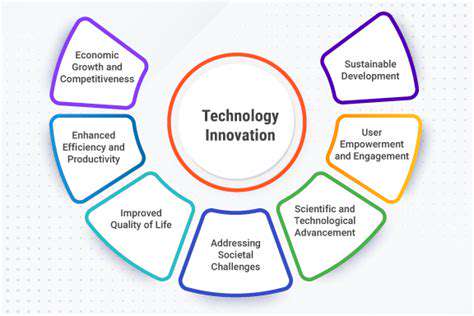

Material Science Horizons

The materials revolution continues accelerating, with new discoveries promising to transform multiple industries. Custom-engineered substances will redefine energy storage, structural design, and vehicle performance.

Emerging technologies like AI-assisted material design are unlocking unprecedented possibilities. This progress points toward a future where materials aren't just selected but precision-engineered for specific automotive applications.

Recycled Materials: A Circular Approach to Automotive Wiring

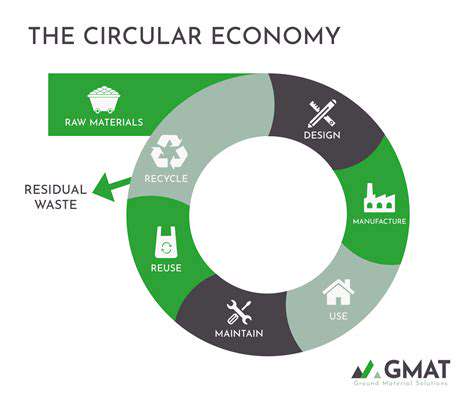

Circular Economy Principles

The automotive industry increasingly adopts circular economy models to reduce waste and resource consumption. Using recycled wiring materials significantly decreases environmental impact while conserving natural resources. This approach helps prevent landfill waste and reduces the need for energy-intensive mining operations.

Transitioning from disposable to reusable materials represents a fundamental shift in manufacturing philosophy. This systemic change promotes responsible production while maintaining material quality and performance standards.

Recycling Technology Breakthroughs

Modern recycling technologies transform waste materials into high-quality automotive components. Advanced sorting systems and purification processes now recover materials previously considered non-recyclable.

New separation techniques produce cleaner recycled materials with properties nearly matching virgin resources. These innovations make recycled wiring materials more viable while reducing processing costs. Some developments even create entirely new material classes from recycled feedstocks.

Digital Tools for Recycling

Specialized applications enhance recycling participation by connecting consumers with recycling networks. These tools provide location-specific guidance to ensure proper material handling and maximize recovery rates.

Digital platforms simplify recycling by offering personalized recommendations and facility information. This technology empowers individuals to contribute effectively to sustainability efforts. Such tools foster environmental responsibility while making recycling more accessible to diverse communities.

The Future of Sustainable Automotive Wiring: Challenges and Opportunities

Sustainable Material Selection

Automakers face complex decisions balancing performance, cost, and environmental impact when selecting wiring materials. Bio-based plastics and recycled metals offer promising alternatives to conventional options, though technical challenges remain.

Designing for Recyclability

Future wiring systems will incorporate modular designs and standardized components to facilitate recycling. Simplifying material combinations and connection methods will streamline end-of-life processing.

Advanced Production Methods

Innovative manufacturing techniques like additive manufacturing minimize waste during production. These methods optimize material usage while maintaining electrical performance requirements.

Performance and Safety Standards

Sustainable materials must meet rigorous automotive performance criteria. Extensive testing ensures reliability under extreme temperature, vibration, and chemical exposure conditions.

Economic Viability

Widespread adoption requires sustainable wiring solutions to achieve cost parity with conventional options. Industry collaboration and policy support can accelerate this transition.

Regulatory Landscape

Government policies increasingly mandate sustainable materials in vehicle manufacturing. Harmonized international standards will encourage global adoption of eco-friendly wiring solutions.