The Role of Brake Fluid in Master Cylinder Function

Brake Fluid Properties and Function

Brake fluid is a critical component in hydraulic braking systems, acting as a crucial medium to transmit pressure from the brake pedal to the brake calipers. Its primary function is to maintain consistent pressure throughout the system, enabling the braking force to be reliably applied. Understanding its properties is essential for ensuring optimal braking performance and safety. Brake fluid's inherent viscosity and boiling point significantly impact the system's effectiveness.

A key aspect of brake fluid function is its ability to withstand high pressure and maintain its viscosity under varying temperatures. This characteristic is vital for ensuring consistent braking force, regardless of the operating conditions.

Master Cylinder Design and Fluid Flow

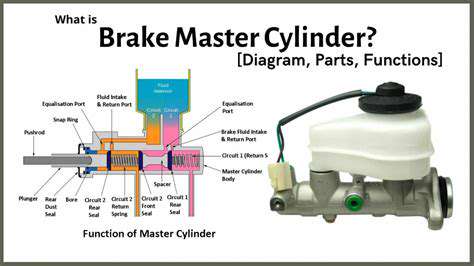

The master cylinder, the heart of the hydraulic braking system, houses the brake fluid and is responsible for amplifying the force applied by the driver's brake pedal. The design of the master cylinder dictates how the brake fluid is moved through the system, directly impacting the overall braking response. Sophisticated designs often incorporate features to improve fluid flow and reduce pressure fluctuations.

Fluid flow within the master cylinder is meticulously engineered to ensure rapid and consistent pressure transfer to the brake lines. This optimized design is crucial for achieving quick and responsive braking.

Brake Fluid Compatibility and Types

Different types of brake fluid are designed to meet varying performance requirements. Compatibility is paramount, as using an incompatible fluid can severely degrade braking performance and even lead to system failure. Choosing the right type of brake fluid is essential for maintaining the integrity of the entire braking system.

The various types of brake fluid are designed with different boiling points and viscosities, each tailored for specific vehicle applications and operating conditions. Understanding these differences is key to selecting the appropriate brake fluid for your vehicle.

Importance of Brake Fluid Maintenance

Regular maintenance of the brake fluid level and quality is crucial for the longevity and performance of the braking system. Proper fluid maintenance helps to ensure consistent braking power and prevent potential failures. This includes checking the fluid level regularly and replacing it at recommended intervals.

Contamination, moisture, and degradation from exposure to air can significantly affect the brake fluid's properties. Regular fluid changes, as recommended by the vehicle manufacturer, are essential to maintain the system's integrity and performance.

Brake Fluid's Role in Safety

Brake fluid plays a critical role in ensuring the safety of the vehicle and its occupants. A properly functioning braking system, with optimal brake fluid, is essential for safe stopping and maneuvering. Its ability to transmit pressure effectively and maintain consistent viscosity under varying conditions contributes significantly to the safety of the driver and passengers.

Maintaining a reliable and efficient braking system is paramount for preventing accidents. A robust brake fluid system, properly maintained, is an integral part of this safety mechanism.

Potential Problems with Brake Fluid

Issues with brake fluid can manifest in various ways, potentially impacting braking performance. Low fluid levels can lead to reduced braking power and, in extreme cases, brake failure. Contamination by moisture or other impurities can affect the fluid's properties and lead to reduced effectiveness.

Furthermore, brake fluid degradation due to age or exposure to heat can negatively affect the system's ability to transmit pressure effectively. Proper maintenance and timely replacement are essential to prevent these issues.

Avoiding Potential Accidents

Visual Inspection for Leaks and Damage

Regularly inspecting the brake master cylinder for any visible signs of leaks or damage is crucial. This involves carefully examining the cylinder's body, hoses, and connections for any fluid spills, cracks, or bulges. Look for any signs of corrosion, which can weaken the components and lead to potential leaks. Pay particular attention to areas where the cylinder connects to the brake lines, as these are common points of failure. A thorough visual inspection can often detect problems before they escalate into major issues.

If you notice any abnormalities, such as a fluid puddle or a cracked component, immediately take your vehicle to a qualified mechanic for further assessment and repair. Prompt action can prevent more extensive damage and potential accidents, saving you money in the long run.

Checking Fluid Levels and Condition

Maintaining the correct brake fluid level is essential for proper brake function. Low fluid levels can lead to reduced braking power and increased stopping distances, significantly increasing the risk of accidents. Always check the brake fluid reservoir level using the dipstick or gauge provided, ensuring the fluid is at the designated level. Additionally, inspect the fluid's color and consistency. Dark, contaminated fluid may indicate the presence of moisture or degradation, which can lead to corrosion and reduced braking efficiency. Keeping the fluid clean and at the proper level is paramount to safe braking.

If the fluid level is low, top it off with the correct type of DOT-approved brake fluid, following the manufacturer's recommendations. Using the incorrect fluid can damage the brake system and compromise its effectiveness, potentially contributing to accidents.

Assessing Pedal Feel and Response

Regularly evaluating the brake pedal feel and response is a vital part of proactive accident prevention. A spongy or soft pedal can indicate a problem with the master cylinder or other components in the brake system. A firm pedal is essential for effective braking, as it indicates proper hydraulic pressure. A gradual decrease in pedal responsiveness could signal a gradual fluid leak or other system issues. Thoroughly assessing the pedal feel is an important aspect of preventative maintenance.

Listening for Unusual Sounds

Pay close attention to any unusual sounds emanating from the brake system, especially when you apply the brakes. A hissing sound might indicate a leak in the brake lines or master cylinder. A grinding or screeching noise could suggest worn or damaged components within the brake system, potentially leading to brake failure. Listening for any abnormalities during normal operation, including when applying the brakes and when the vehicle is at rest, can help in identifying potential issues early on.

Professional Inspection and Maintenance

While visual inspections and basic fluid checks are important, professional inspection and maintenance should be performed at regular intervals. A qualified mechanic has the expertise and specialized tools to thoroughly assess the brake master cylinder and related components. This includes checking for internal damage, examining the seals and pistons, and ensuring the integrity of the entire system. Regular professional inspections can prevent potential issues from escalating into catastrophic failures, ultimately reducing the risk of accidents.

Professional maintenance, such as replacing worn parts or addressing identified issues, will significantly extend the life of the brake master cylinder and ensure optimal braking performance. This proactive approach contributes significantly to overall safety and reduces the risk of accidents related to brake failure.