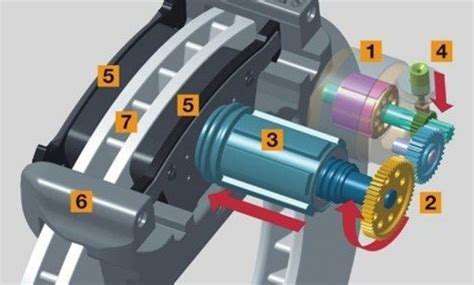

Enhanced Driving Experience

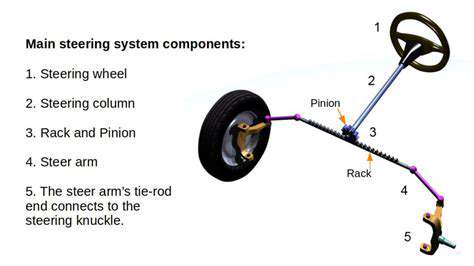

Power steering significantly improves the driving experience, particularly in challenging situations. It dramatically reduces the effort required to turn the steering wheel, making maneuvering in tight spaces, parking, and navigating hilly or rough terrain significantly easier. This ease of operation translates to a more comfortable and enjoyable driving experience, especially for drivers who spend extended periods on the road or encounter frequent obstacles.

The reduced physical exertion also contributes to a more fatigue-free driving experience, as drivers aren't constantly straining their arms and shoulders. This is crucial for safety, as fatigued drivers are more prone to errors and accidents. The enhanced control and precision offered by power steering contribute to a smoother and more confident handling experience, allowing for greater precision during turns and more responsive control over the vehicle's direction.

Improved Safety and Efficiency

Beyond comfort, power steering plays a vital role in enhancing safety. The reduced steering effort allows drivers to react more quickly to unexpected situations, such as avoiding obstacles or correcting steering errors. This responsiveness is crucial in emergency situations, where milliseconds can make a significant difference in avoiding accidents. The reduced physical strain also contributes to the driver's ability to maintain focus and alertness throughout the journey.

Furthermore, power steering contributes to fuel efficiency. By reducing the effort required to steer, it minimizes the strain on the engine, thus lowering fuel consumption. This translates to lower operating costs for vehicle owners, making power steering a beneficial feature for both economic and environmental reasons. The smoother and more controlled driving experience also helps to maintain a consistent speed and prevent unnecessary acceleration and deceleration, both contributing to better fuel economy.

Maintenance and Long-Term Value

While power steering systems require periodic maintenance, such as fluid checks and component inspections, the benefits often outweigh the costs. Proper maintenance ensures the system functions optimally, extending its lifespan and preventing potential breakdowns. Regular maintenance also contributes to the overall health and longevity of the vehicle, preserving its value over time.

The enhanced control and reduced stress on the steering components, facilitated by power steering, can contribute to a longer lifespan for the entire steering system. This translates to potentially lower repair costs and extended use of the vehicle's components, thus increasing the overall value and reliability of the vehicle. Consequently, a well-maintained power steering system can contribute to a longer vehicle lifespan and higher resale value, increasing the overall return on investment for the vehicle owner.

Maintenance and Troubleshooting Power Steering Systems

Preventive Maintenance

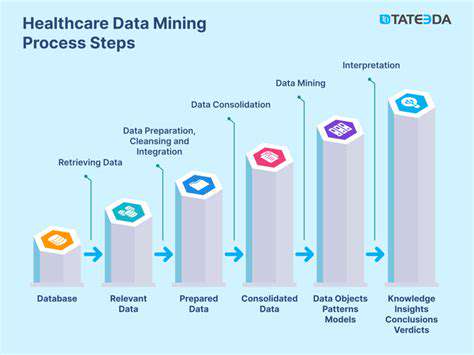

Regular preventive maintenance is crucial for ensuring the longevity and optimal performance of your equipment. Proactive maintenance, rather than reactive fixes, significantly reduces the risk of costly breakdowns and downtime. This involves scheduled inspections, cleaning, lubrication, and replacement of parts based on manufacturer recommendations and usage patterns. By staying ahead of potential problems, you can avoid unexpected emergencies and maintain a consistent workflow.

Implementing a robust preventive maintenance schedule allows for a more predictable and controlled operational environment. This proactive approach not only minimizes the likelihood of equipment failures but also enhances the overall efficiency of your systems. Detailed records of maintenance activities are essential to track performance trends, identify potential issues early on, and make informed decisions about future maintenance requirements.

Troubleshooting Common Issues

When encountering problems, systematic troubleshooting is key. First, thoroughly identify the symptoms of the malfunction. Documenting these details is essential for accurate diagnosis and effective repair. Gather information about the equipment's usage history, recent maintenance activities, and any unusual events that may have preceded the problem.

Consult the equipment's user manual or technical documentation for troubleshooting guides and diagnostic procedures. Reference specific error codes or warning messages to pinpoint the source of the problem. If the issue persists after these initial steps, contact qualified technicians for professional assistance.

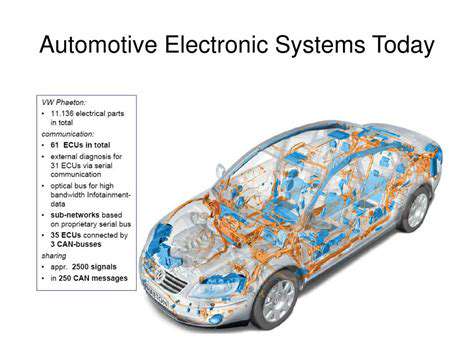

Error Codes and Diagnostics

Understanding and interpreting error codes is vital for efficient troubleshooting. These codes often provide specific insights into the nature of the malfunction, guiding technicians toward the necessary repairs. Familiarize yourself with the specific error codes relevant to your equipment and their corresponding solutions. Refer to the manufacturer's documentation for a comprehensive list of error codes and their meanings.

Employing diagnostic tools can further enhance the accuracy of your troubleshooting efforts. These tools often provide real-time data about the equipment's performance, enabling you to identify potential problems before they escalate into major malfunctions. Utilizing these tools can significantly reduce the time and resources needed for repairs.

Safety Precautions

Prioritizing safety is paramount during any maintenance or troubleshooting procedure. Always ensure that the equipment is properly shut down and isolated from power sources before performing any work. Use appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, to mitigate potential risks. Adhere to all safety protocols outlined in the equipment's operating manual and company safety guidelines.

Furthermore, be mindful of potential hazards associated with specific tasks. If you are unsure about a particular procedure or safety precaution, consult with a qualified technician or supervisor. Proper safety measures are crucial for preventing accidents and injuries during maintenance activities.