The Significant Water Footprint of Automotive Manufacturing

The Water-Intensive Processes

Automotive manufacturing relies heavily on water for a multitude of crucial processes, from cleaning and cooling components to shaping metal and transporting materials. The sheer volume of water used across different stages of production, from initial material processing to final assembly, creates a significant water footprint. This encompasses everything from the water used in the production of raw materials, like steel and plastics, to the massive amounts required for cleaning and rinsing parts throughout the assembly line.

Understanding the specific water demands of each stage is crucial to identifying areas for potential optimization. For instance, the processes involved in casting and machining metal components often necessitate substantial quantities of cooling water. This highlights the need for innovative approaches to minimize water consumption in these critical stages of production.

Impact on Water Resources

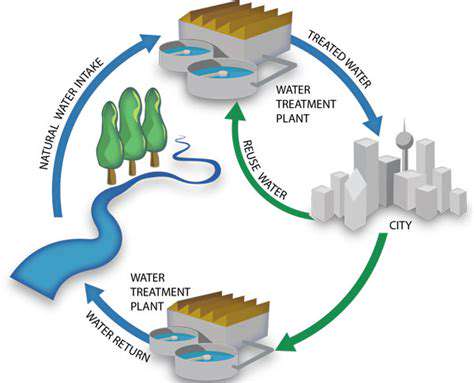

The significant water footprint of automotive manufacturing places a considerable strain on local water resources, particularly in regions already facing water scarcity. The extraction and use of such large quantities of water can exacerbate existing water stress, impacting agriculture, ecosystems, and human communities that depend on the same water sources. Additionally, the discharge of wastewater from manufacturing plants, if not properly treated, can lead to water pollution, further degrading water quality and harming the environment.

Opportunities for Water Efficiency

Despite the inherent water intensity of automotive manufacturing, there are numerous opportunities to enhance water efficiency and reduce the overall water footprint. Implementing advanced water treatment and recycling systems can significantly decrease the amount of fresh water required. Moreover, process modifications that minimize water usage, coupled with the careful selection of water-efficient materials and technologies, can yield substantial improvements.

Innovative Water Management Strategies

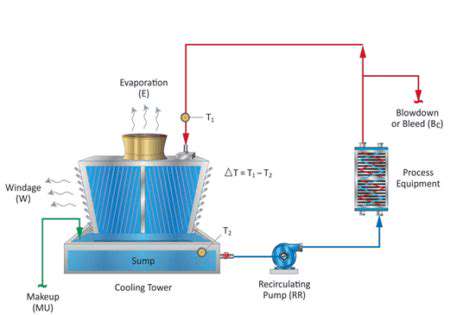

Adopting water-efficient technologies and strategies is paramount to sustainable automotive production. This includes implementing closed-loop water systems, where water is reused and recycled within the manufacturing process. The integration of advanced sensors and data analytics can also provide real-time insights into water usage, enabling proactive adjustments and optimized resource allocation.

The Role of Sustainable Materials

The selection of sustainable materials in the manufacturing process can also play a crucial role in reducing the overall water footprint. Materials with lower water-intensive production processes can contribute significantly to a more environmentally conscious manufacturing approach. This includes exploring alternatives to traditional materials where possible and focusing on materials whose production process doesn't necessitate large amounts of water.

Industry Collaboration and Standards

Collaboration among automotive manufacturers, suppliers, and government agencies is critical to establishing and enforcing water conservation standards and best practices. The development of industry-wide guidelines and standards for water usage in manufacturing can create a shared framework for minimizing environmental impact. Such collaborative efforts can drive innovation and ensure consistent application of water-efficient methods across the entire automotive supply chain.

Consumer Awareness and Responsibility

Ultimately, consumers have a role to play in promoting water conservation within the automotive industry. By supporting manufacturers who prioritize water efficiency and sustainable practices, consumers can indirectly influence the industry's commitment to responsible water management. Understanding the water footprint of vehicles and choosing models with lower water-intensive manufacturing processes are steps consumers can take to reduce their collective impact on water resources.

Optimizing Cooling Systems and Processes

Optimizing Cooling System Efficiency

Improving the efficiency of cooling systems is crucial for reducing energy consumption and minimizing environmental impact. Modern advancements in technology, such as variable-speed drives and advanced control systems, enable significant improvements in energy efficiency. Implementing these technologies can lead to substantial cost savings over the lifespan of the cooling system, and these savings are directly reflected in reduced operating expenses. This optimization process involves a thorough evaluation of existing systems to identify areas for improvement, and careful consideration of potential upgrades and replacements.

A key aspect of optimizing cooling systems is the careful selection of components. Choosing high-efficiency motors, optimized refrigerant types, and advanced insulation materials can drastically reduce energy losses. These choices are crucial in achieving the desired levels of cooling performance without excessive energy consumption. This approach not only lowers operating costs but also contributes to a smaller carbon footprint.

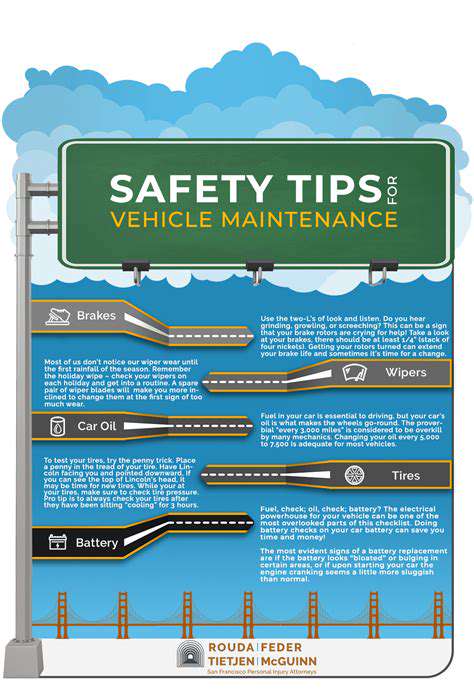

Proactive Maintenance Strategies

Proactive maintenance is essential for ensuring the longevity and efficiency of cooling systems. Regular inspections and maintenance tasks, such as cleaning coils, checking refrigerant levels, and lubricating moving parts, can prevent potential breakdowns and system failures. This preventive approach is far more cost-effective than dealing with costly repairs or replacements due to breakdowns.

Routine maintenance minimizes the risk of unexpected equipment failures and ensures that the cooling system operates at peak efficiency. This is vital for maintaining consistent comfort levels and preventing costly downtime. Moreover, timely maintenance can help to detect potential issues early on, often before they escalate into significant problems.

Implementing a structured preventative maintenance schedule is a key strategy for optimizing cooling system performance over the long term. This includes regular inspections, component checks, and necessary repairs or replacements. This approach also helps to extend the lifespan of the cooling system, which means reduced replacement costs down the road.

Understanding System Integration

A crucial aspect of optimizing cooling systems involves understanding the integration of the cooling system with other building systems. For example, carefully considering the interaction between the cooling system and the building's HVAC system, electrical infrastructure, and other utilities is essential. This holistic approach ensures that all components work together seamlessly and efficiently.

Optimizing the integration of the cooling system with other building systems often involves careful coordination between different engineering disciplines, including HVAC, electrical, and structural engineering. This process ensures the system's efficient operation while minimizing any potential conflicts or disruptions.

Data-Driven Approaches and Continuous Improvement

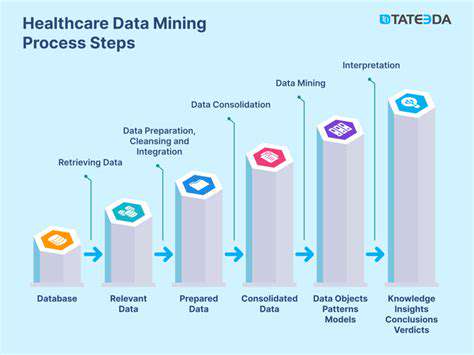

Data-Driven Decision Making in Modern Business

Data-driven decision-making is rapidly becoming the cornerstone of success in today's dynamic business environment. Companies are increasingly recognizing the power of leveraging data to identify trends, predict future outcomes, and optimize operations. This approach allows businesses to make more informed choices, reduce risks, and ultimately, achieve greater profitability. By analyzing vast amounts of data, companies can gain invaluable insights into customer behavior, market trends, and internal processes. This knowledge empowers them to tailor strategies, products, and services to meet the evolving needs of their target audience.

The ability to process and interpret data effectively is crucial for adapting to changing market conditions. Companies that embrace data-driven strategies are better positioned to respond to emerging opportunities and mitigate potential threats. This forward-thinking approach enables them to stay ahead of the curve and maintain a competitive edge in the marketplace. Constantly monitoring and analyzing data allows for quicker adjustments to strategies, ensuring that resources are allocated efficiently and maximizing returns on investment.

Continuous Improvement Through Data Analysis

The continuous analysis of data allows businesses to identify areas for improvement within their operations. By tracking key performance indicators (KPIs) and meticulously examining patterns and trends, companies can pinpoint bottlenecks, inefficiencies, and areas where processes can be streamlined. This iterative approach fosters a culture of continuous improvement, ultimately leading to enhanced productivity and greater overall efficiency.

Data analysis provides a clear picture of strengths and weaknesses, enabling targeted interventions. For example, identifying a drop in sales in a particular region can trigger a focused investigation into the potential causes. This focused analysis might reveal issues with marketing campaigns, logistical challenges, or a shift in consumer preferences. Addressing these issues proactively leads to a more robust and adaptable business model.

Leveraging Data for Strategic Planning and Forecasting

Data-driven insights are invaluable for strategic planning and forecasting. By analyzing historical data and market trends, companies can develop accurate projections about future performance and make well-informed decisions regarding resource allocation and investment strategies. This predictive capability enables businesses to anticipate potential challenges and opportunities, allowing for proactive adaptation and effective risk management.

Using historical data, companies can create realistic models for future scenarios. These models provide a framework for assessing various strategic options and determining the most promising path forward. This approach helps mitigate risks by providing a better understanding of potential outcomes under different circumstances. The ability to anticipate and prepare for future challenges is crucial for long-term success and sustainability.

Furthermore, data-driven forecasting allows companies to make more precise estimations of demand, optimize inventory management, and improve supply chain efficiency. By leveraging data insights, companies can fine-tune their operations to better meet customer needs and ensure timely delivery of products and services. This contributes significantly to customer satisfaction and strengthens the company's reputation. Ultimately, this leads to a more sustainable and profitable business model.