The Growing Importance of Sustainable EV Supply Chains

Sustainable Sourcing of Critical Minerals

The electric vehicle (EV) revolution hinges on a robust and sustainable supply chain for critical minerals like lithium, cobalt, nickel, and graphite. These minerals are essential components in EV batteries, and their extraction, processing, and transportation often involve significant environmental and social challenges. Sustainable practices in these areas, such as responsible mining techniques, reducing water consumption, and ensuring fair labor standards, are crucial for ensuring the long-term viability and ethical production of EV batteries. This requires a shift towards closed-loop systems and the development of alternative battery chemistries to minimize reliance on specific minerals.

Companies must actively engage with suppliers and communities to ensure that the entire supply chain adheres to stringent environmental and social standards. This includes supporting responsible mining practices, investing in sustainable extraction technologies, and fostering transparency throughout the value chain. The future of sustainable EV supply chains depends on proactive measures to address these complex challenges, ensuring that the transition to EVs doesn't come at the cost of environmental degradation or social injustice.

Manufacturing Processes and Energy Efficiency

The manufacturing of EV components, including batteries, motors, and power electronics, requires significant energy and resources. Sustainable EV supply chains must prioritize energy efficiency in manufacturing processes, exploring renewable energy sources and reducing reliance on fossil fuels. Optimization of production techniques to minimize waste and emissions is equally important. This involves implementing lean manufacturing principles, adopting circular economy models, and utilizing recycled materials wherever possible.

Moreover, the choice of manufacturing location plays a crucial role in sustainability. Companies should consider factors such as proximity to renewable energy sources, efficient transportation networks, and supportive government policies when selecting manufacturing sites. This strategic decision-making can significantly reduce the carbon footprint associated with the production process and promote a more sustainable future for the EV industry.

Transportation and Logistics Optimization

The transportation of EV components and finished vehicles across the globe is a significant contributor to the overall carbon footprint of the EV supply chain. Sustainable supply chains must prioritize optimized transportation routes and efficient logistics networks to minimize transportation emissions. This includes leveraging technologies like electric vehicles for transportation within the supply chain, exploring alternative fuels, and reducing the overall distance traveled. The use of advanced logistics management systems, including real-time tracking and predictive analytics, can further enhance the efficiency and sustainability of the entire process.

Furthermore, the development of more environmentally friendly packaging materials and the optimization of delivery routes are essential steps toward minimizing the environmental impact of transportation. Sustainable supply chains must consider all aspects of the transportation process, from raw material extraction to final delivery, to ensure a truly eco-friendly and efficient EV ecosystem.

Manufacturing Processes and Waste Reduction

Optimizing Manufacturing Processes for Waste Reduction

Modern manufacturing processes often generate significant amounts of waste, impacting both the environment and profitability. Sustainable supply chains for electric vehicles require a fundamental shift towards minimizing waste at every stage, from material sourcing to product disposal. This involves meticulous planning and optimization of production lines, incorporating lean manufacturing principles and exploring innovative technologies to reduce material consumption and energy expenditure. Implementing strategies like 5S methodology, value stream mapping, and automation can substantially decrease waste and improve efficiency. Furthermore, a focus on pre-production planning, such as designing for recyclability and reusability, is crucial for long-term sustainability.

Waste reduction efforts extend beyond the factory floor to include raw material selection. Sustainable sourcing practices, such as partnering with suppliers committed to ethical and environmentally conscious production, are vital. This approach not only minimizes the environmental footprint associated with material extraction but also builds trust and transparency throughout the supply chain, a key element in building a sustainable future.

Material Selection and Recycling Strategies

Choosing appropriate materials is paramount in minimizing waste throughout the entire lifecycle of an electric vehicle. Lightweight materials, such as aluminum and carbon fiber composites, can reduce the overall weight of the vehicle, leading to improved energy efficiency and reduced manufacturing needs. However, the selection process should also consider the recyclability and reusability of these materials. This includes assessing the feasibility of material recovery and exploring innovative recycling methods to ensure the materials can be returned to the production cycle, minimizing the need for new resource extraction.

Energy Efficiency and Renewable Energy Integration

Manufacturing processes for electric vehicles consume substantial amounts of energy. Integrating renewable energy sources into the production facilities can significantly reduce the carbon footprint. This involves exploring solar, wind, or hydro power options and optimizing the energy consumption of the manufacturing equipment. Utilizing energy-efficient technologies and implementing smart energy management systems can further optimize energy use. Sustainable supply chains should also consider the energy efficiency of the transportation systems used to move materials and finished products throughout the supply chain.

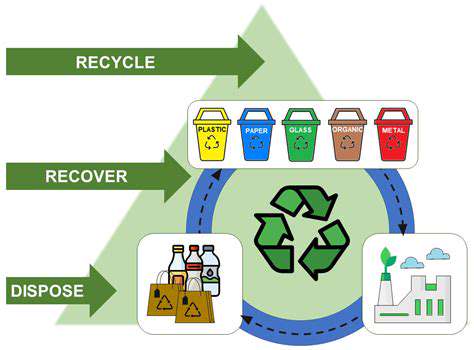

Waste Management and Disposal Strategies

Effective waste management systems are crucial for mitigating environmental impacts. Developing comprehensive waste segregation and recycling programs within the manufacturing facility is essential. This includes separating hazardous materials from non-hazardous waste to ensure proper disposal and minimize pollution. Implementing robust waste disposal strategies that adhere to environmental regulations and promote responsible end-of-life management of electric vehicle components are key aspects of a sustainable supply chain.

Supply Chain Transparency and Collaboration

Building a sustainable supply chain requires transparency and collaboration across all stakeholders. This includes open communication with suppliers and customers about environmental performance and waste reduction efforts. Implementing traceability systems to track materials from origin to final product is essential to ensure transparency and accountability. Collaboration between manufacturers, suppliers, and governments is vital to develop and implement effective waste reduction policies and share best practices within the industry. This collaborative approach fosters a culture of sustainability throughout the entire supply chain, ensuring environmental responsibility and ethical practices are embedded in every step of the process.

Building Transparency and Accountability

Enhanced Supplier Relationships

Building transparent and accountable supply chains for electric vehicles (EVs) necessitates fostering strong relationships with suppliers. This involves open communication channels, clear expectations, and a shared commitment to ethical sourcing and environmental responsibility. Collaboration on sustainability initiatives, such as reducing carbon footprints and improving working conditions, is crucial for driving positive change throughout the entire supply chain. This collaborative approach not only mitigates risks but also unlocks opportunities for innovation and efficiency.

Establishing trust with suppliers is paramount. Open dialogue about sustainability goals, performance metrics, and challenges is essential for building a foundation of mutual respect and shared responsibility. Regular audits and assessments, conducted transparently, can ensure compliance with ethical and environmental standards, fostering a culture of continuous improvement within the supply chain.

Data-Driven Traceability

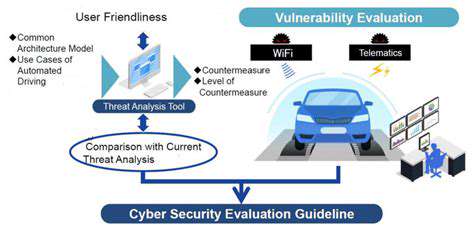

Implementing robust data management systems is essential for achieving transparency and accountability in EV supply chains. This includes tracking materials from origin to production, enabling detailed audits and providing insights into the entire manufacturing process. Detailed records of material sourcing, processing, and transportation contribute significantly to the overall traceability of components within the EV supply chain. This approach allows for rapid identification of potential issues and facilitates swift corrective action.

Ethical Sourcing Practices

A core component of sustainable supply chains is ensuring ethical sourcing practices. This encompasses fair labor standards, including fair wages, safe working conditions, and the prohibition of child labor. Beyond labor standards, it also extends to responsible sourcing of raw materials, minimizing environmental impact at every stage of production, and promoting the use of recycled and renewable resources. Adhering to strict ethical standards ensures that the entire supply chain operates with integrity and respect.

Environmental Impact Assessment

Thorough environmental impact assessments are critical for understanding and minimizing the environmental footprint of EV production. These assessments should evaluate the environmental impact of each stage of the supply chain, from raw material extraction to final product disposal. This includes analyzing energy consumption, water usage, waste generation, and greenhouse gas emissions throughout the entire life cycle of the vehicle. By proactively identifying and addressing environmental risks, companies can contribute to a more sustainable future.

Supply Chain Risk Management

Effective supply chain risk management is crucial for the resilience and sustainability of EV production. This involves identifying and assessing potential disruptions, such as geopolitical instability, natural disasters, or material shortages. Proactive mitigation strategies, contingency plans, and diversification of suppliers are essential to minimize the impact of these risks. Building a robust and adaptable supply chain is vital for ensuring consistent production and delivery of EV components.

Transparency in Communication

Open and transparent communication throughout the supply chain is paramount. This includes regular reporting on sustainability performance, sharing best practices, and proactively addressing concerns. Clear communication fosters trust and accountability among all stakeholders, from suppliers to consumers. Transparency builds confidence and encourages collaboration, allowing for the efficient resolution of issues and continuous improvement throughout the supply chain.

Financial Accountability and Incentives

Establishing clear financial accountability mechanisms and incentives is crucial for encouraging sustainable practices within the EV supply chain. This includes implementing performance-based contracts that reward suppliers for their commitment to sustainability. Transparent financial reporting and auditing mechanisms can ensure that resources are allocated effectively and that progress towards sustainability targets is accurately measured. Incentivizing environmentally responsible practices fosters a culture of sustainability within the supply chain.