Innovative materials science, such as the development of high-strength alloys and composites, plays a pivotal role in achieving this goal. These materials not only reduce the overall mass of the vehicle but also enhance its structural rigidity and durability, leading to improved fuel efficiency and reduced emissions.

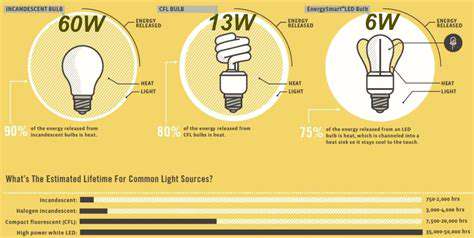

Optimizing Energy Consumption

Fuel efficiency is paramount in the automotive sector. Manufacturers are continuously striving to improve the energy efficiency of vehicles through advancements in engine technology, aerodynamic design, and the integration of advanced driver-assistance systems (ADAS). Reducing energy consumption not only benefits drivers by lowering fuel costs but also contributes significantly to mitigating the environmental impact of automobiles.

Strategies like regenerative braking and optimized gear ratios are critical components in achieving enhanced fuel efficiency. Furthermore, the incorporation of electric and hybrid powertrains further minimizes the reliance on fossil fuels, paving the way for a more sustainable future.

Sustainable Manufacturing Processes

The manufacturing processes employed in the automotive industry have a significant environmental footprint. Transitioning to more sustainable manufacturing practices is essential for reducing the industry's overall carbon emissions and minimizing waste generation. This includes adopting lean manufacturing principles, implementing closed-loop recycling systems, and utilizing renewable energy sources in production facilities.

Implementing these sustainable practices not only reduces the environmental impact but also fosters a more responsible and ethical corporate image, attracting environmentally conscious consumers.

Recycling and Waste Management

Efficient recycling and waste management systems are critical for the long-term sustainability of the automotive industry. Developing robust recycling infrastructure for end-of-life vehicles (ELVs) is paramount. This includes properly separating different materials, such as metals, plastics, and glass, to maximize their reuse value. Innovative recycling techniques, coupled with the development of advanced materials that are easily recyclable, are crucial for minimizing the environmental burden of vehicle disposal.

Advanced Material Research and Development

Advanced material research and development are essential for achieving significant gains in resource efficiency. The exploration of new and innovative materials, such as bio-based plastics and recycled metals, is crucial for reducing the reliance on virgin resources. This research and development not only addresses the need for sustainable materials but also opens doors for the creation of vehicles with enhanced performance characteristics and reduced environmental impact.

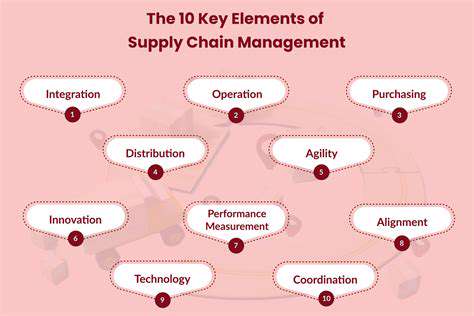

Supply Chain Optimization

Optimizing the automotive supply chain is vital for minimizing resource consumption and maximizing efficiency. This involves developing strategies to reduce transportation distances, optimize logistics, and implement sustainable sourcing practices for raw materials. Collaboration with suppliers who share a commitment to environmental responsibility is essential for building a more sustainable supply chain and reducing the environmental footprint of the entire production process.

Consumer Awareness and Education

Ultimately, promoting consumer awareness and education regarding resource-efficient vehicles is crucial for the wider adoption of sustainable practices. Educating consumers about the benefits of choosing fuel-efficient vehicles, prioritizing sustainable manufacturing processes, and supporting recycling initiatives can drive significant change. By empowering consumers with knowledge, the automotive industry can foster a culture of responsible consumption and pave the way for a truly sustainable future.

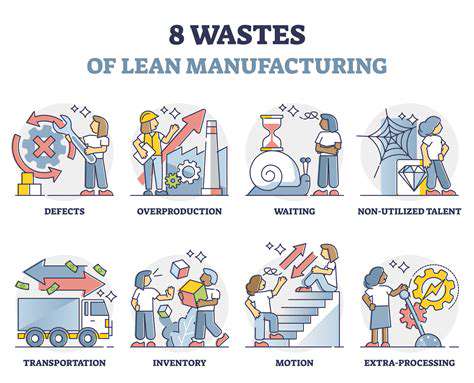

Lean Manufacturing Principles for Waste Reduction

Implementing Lean Principles in Manufacturing

Lean manufacturing principles, rooted in efficiency and waste reduction, are crucial for modern manufacturing operations. These principles aim to streamline processes, minimize inventory, and ultimately increase profitability. Implementing these principles requires a significant cultural shift within the organization, moving from a traditional, often reactive, approach to a proactive, continuous improvement mindset. This shift demands a commitment to identifying and eliminating all forms of waste, from excess inventory to unnecessary motion within the production line. Adopting a systematic approach to problem-solving and focusing on the needs of the customer are essential elements of this transformation.

A key component of lean manufacturing is the concept of value stream mapping. This visual representation of the entire production process allows for a clear identification of bottlenecks and non-value-added activities. By understanding where time and resources are being wasted, organizations can implement targeted improvements that have significant impacts on overall productivity. A clear understanding of the value stream allows for the identification of areas where adjustments to workflow can drastically improve the efficiency and effectiveness of the entire production process.

Key Lean Manufacturing Tools and Techniques

Various tools and techniques are integral to the successful implementation of lean manufacturing principles. One such tool is 5S, a methodology focused on workplace organization and standardization. By implementing 5S, manufacturers can create a more efficient and safer work environment. This systematic approach to workplace organization leads to a reduction in waste and an increase in overall productivity. 5S principles encompass sorting, setting in order, shining, standardizing, and sustaining, each step contributing to a more streamlined and productive work environment.

Another crucial lean tool is Kanban. This system visually manages workflow and inventory levels, ensuring that materials are available when needed and reducing excess inventory. Kanban helps to optimize material flow and minimize the risk of production delays or shortages. By improving communication and visibility throughout the process, Kanban fosters a more responsive and efficient manufacturing operation. Using Kanban boards helps to identify potential issues and bottlenecks quickly, allowing for immediate corrective actions.

Furthermore, value stream mapping, as previously mentioned, is a powerful technique for analyzing the entire production process. By identifying bottlenecks and non-value-added activities, organizations can implement targeted improvements. This analysis allows for a deeper understanding of the process flow and the identification of areas where significant improvement can be made.

These methodologies and tools, when implemented correctly, will help companies move towards a more efficient and customer-centric manufacturing process.

Green Initiatives for Environmental Sustainability

Sustainable Practices in Agriculture

Implementing sustainable agricultural practices is crucial for minimizing environmental impact. Adopting no-till farming methods can significantly reduce soil erosion and improve water retention, contributing to a healthier ecosystem. This approach minimizes the disturbance of the soil, fostering a more resilient agricultural system. Furthermore, integrating crop rotation and cover cropping can enhance soil fertility and reduce the reliance on synthetic fertilizers, ultimately promoting biodiversity and minimizing pollution.

Encouraging the use of drought-resistant crops and efficient irrigation systems is also vital. These strategies help conserve water resources, a precious commodity in many regions facing water scarcity. By optimizing water usage, we can safeguard water supplies for future generations and reduce the strain on ecosystems.

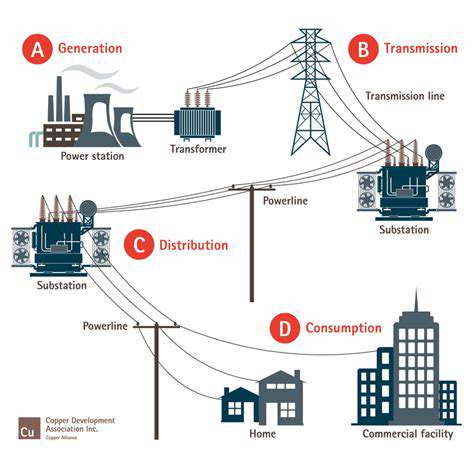

Renewable Energy Sources

Transitioning to renewable energy sources is paramount for mitigating greenhouse gas emissions and promoting a cleaner energy future. Investing in solar, wind, and hydro power can drastically reduce reliance on fossil fuels and lower carbon footprints. This shift not only safeguards the environment but also creates new job opportunities in the renewable energy sector.

Furthermore, exploring innovative approaches to energy storage, such as battery technology advancements, is crucial for ensuring the reliability and consistency of renewable energy supply. This will further drive the widespread adoption of sustainable energy alternatives.

Waste Management Strategies

Implementing robust waste management strategies is essential to minimizing landfill waste and promoting resource recovery. Effective waste segregation and recycling programs are crucial to divert materials from landfills and promote the circular economy. These strategies reduce the strain on landfills, conserve resources, and minimize pollution.

Encouraging composting and reducing single-use plastics are critical steps in this process. This can significantly reduce the amount of waste sent to landfills and decrease the environmental burden of plastic pollution. Moreover, promoting responsible consumption and reducing waste at its source is a critical component of any successful waste management plan.

Conservation of Natural Resources

Protecting and restoring natural habitats is vital for maintaining biodiversity and preserving ecological balance. Conserving forests, wetlands, and other natural areas is crucial for safeguarding plant and animal species. Protecting these environments also ensures the vital ecosystem services they provide, such as clean water and air.

Implementing sustainable forestry practices, such as selective logging and reforestation efforts, can help maintain the health of our forests. This will help sustain the valuable resources that forests provide for both the environment and society.

Sustainable Transportation Systems

Promoting sustainable transportation systems is critical for reducing air pollution and greenhouse gas emissions. Encouraging the use of public transportation, cycling, and walking can significantly reduce the environmental impact of commuting. These modes of transport are crucial for reducing our dependence on private vehicles and their associated pollution.

Investing in electric vehicles and developing more efficient public transportation networks are also essential steps towards a sustainable future. These improvements will significantly contribute to reducing our reliance on fossil fuels and improving air quality in our communities.

Sustainable Consumption and Production

Promoting sustainable consumption and production patterns is crucial for minimizing environmental impact. Reducing unnecessary consumption and embracing reuse and repair are vital steps. This approach minimizes the demand for new resources and reduces waste generation. By adopting a more conscious consumption pattern, we can significantly reduce our ecological footprint and support a more sustainable future.

Supporting businesses that prioritize sustainability and choosing products with minimal environmental impact are critical components in achieving this goal. This conscious consumerism is a powerful tool in driving positive change across industries.