Environmental Impact of Mining

The extraction of raw materials for EV batteries, particularly lithium, cobalt, nickel, and manganese, often involves significant environmental damage. Open-pit mining can lead to habitat destruction, soil erosion, and water contamination. These impacts extend far beyond the immediate mining site, affecting surrounding ecosystems and potentially impacting human health through the release of harmful chemicals and pollutants into the air and water.

Supply Chain Transparency and Traceability

Lack of transparency and traceability in the EV battery supply chain is a major concern. It's difficult to know the precise origin of raw materials and the environmental and labor practices used in their extraction and processing. This lack of visibility makes it challenging to hold companies accountable for their environmental footprint and ensures that ethical sourcing is not always a priority.

This opacity can also conceal potential human rights abuses, such as child labor or unsafe working conditions, within the supply chain. Consumers and investors have a right to know the complete story behind the batteries powering their vehicles.

Sustainable Alternatives and Resource Management

Developing sustainable alternatives to conventional raw material extraction is crucial for mitigating the environmental impact of EV battery production. Research into recycling technologies, the use of secondary materials, and the exploration of alternative battery chemistries that require less environmentally damaging raw materials are essential for a greener future. Efficient resource management in the mining process, such as minimizing water usage and implementing waste reduction strategies, are key to minimizing environmental damage.

Land Degradation and Biodiversity Loss

The large-scale extraction of raw materials for EV batteries often leads to significant land degradation. Mining activities can destroy natural habitats, displacing wildlife and disrupting ecosystems. The loss of biodiversity in these areas can have cascading effects throughout the environment, impacting the delicate balance of nature. Reforestation and habitat restoration efforts must be prioritized to mitigate these negative impacts.

Water Pollution and Contamination

The extraction and processing of raw materials for EV batteries can contaminate water sources with heavy metals, chemicals, and other pollutants. This poses a significant risk to aquatic life and human populations who rely on these water resources for drinking and other essential needs. Stricter regulations and monitoring mechanisms are needed to ensure that water bodies are not irreversibly harmed during the extraction process. Responsible water management practices are also essential for minimizing the risk of contamination.

Labor Practices and Ethical Considerations

The extraction and processing of raw materials for EV batteries often involve challenging labor practices, particularly in developing countries. Workers may face unsafe working conditions, low wages, and limited access to essential resources. Ethical considerations must be prioritized throughout the supply chain to ensure fair treatment and decent wages for all involved in the production process. Promoting fair labor practices is not only morally right but also crucial for building a sustainable and equitable future for all.

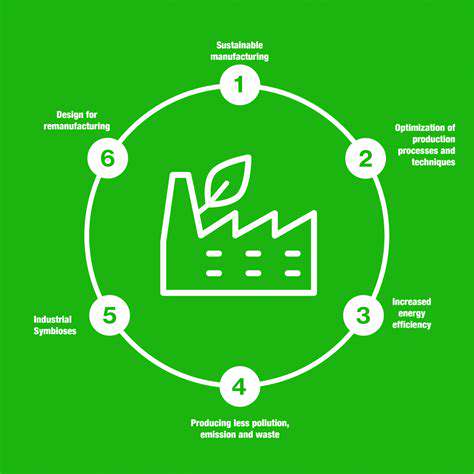

Manufacturing Processes: Energy Consumption and Waste Generation

Energy Consumption in Manufacturing

Manufacturing processes are inherently energy-intensive, consuming a significant portion of global energy resources. Understanding and optimizing energy usage in these processes is crucial for sustainability and cost reduction. Minimizing energy consumption throughout the production chain is a key factor in achieving environmentally friendly manufacturing practices. This includes not only the direct energy used in machinery but also the indirect energy consumed in transportation and material handling.

The energy consumption profile varies greatly depending on the specific manufacturing process. For example, industries like steel production require massive amounts of energy for smelting and shaping, while electronics manufacturing might consume a substantial amount of energy during the assembly and testing phases. A comprehensive approach to reducing energy consumption must consider the unique needs of each process.

Raw Material Acquisition and Processing

The acquisition and initial processing of raw materials often represent a significant portion of energy consumption in manufacturing. Extraction, transportation, and preliminary processing stages can involve substantial energy inputs, leading to substantial carbon footprints. Efficient sourcing and processing strategies are critical to minimizing energy use from the very start of the manufacturing chain.

Manufacturing Equipment and Machinery

Modern manufacturing facilities rely heavily on sophisticated equipment and machinery. The energy efficiency of these machines plays a pivotal role in overall energy consumption. Advanced technologies such as energy-efficient motors, variable-speed drives, and automated systems can significantly reduce energy waste in manufacturing processes. Optimizing the operation of these machines is crucial for lowering the energy bill and reducing the environmental impact of the manufacturing process.

Regular maintenance and upgrades of existing equipment are essential to maintaining optimal energy efficiency. Outdated machinery often has significantly higher energy consumption rates compared to modern, energy-efficient alternatives.

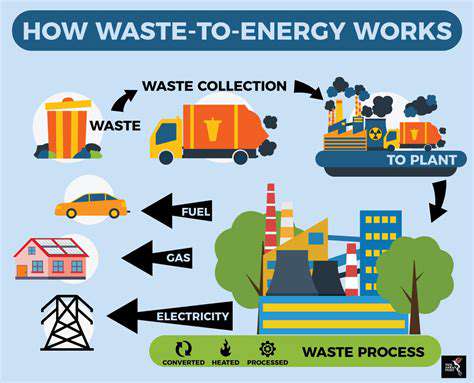

Waste Management and Recycling

Waste generation is an inherent part of manufacturing processes. Managing waste effectively and implementing recycling programs can significantly reduce the overall energy footprint. Waste incineration and material recovery processes can often reclaim energy and valuable resources, reducing the need for new raw material acquisition, which in turn reduces energy consumption.

Transportation and Logistics

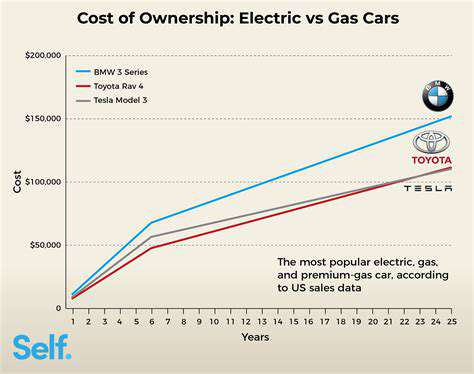

Transportation of raw materials, work-in-process, and finished goods is a significant contributor to overall energy consumption. Efficient logistics, optimized delivery routes, and the use of sustainable transportation methods like electric vehicles are vital to reducing energy consumption in this crucial stage. Minimizing transportation distances and utilizing optimized delivery schedules can significantly reduce the environmental impact of manufacturing.

Product Design and Lifecycle Analysis

The design phase of a product plays a critical role in the overall energy consumption throughout its entire lifecycle. Designing products with energy efficiency in mind from the outset can significantly reduce energy consumption during manufacturing, use, and disposal. Considering the entire lifecycle of a product, from raw materials to end-of-life disposal, is crucial for sustainable manufacturing practices. Lifecycle assessments (LCA) are vital tools for identifying energy consumption hotspots.

Environmental Regulations and Standards

Government regulations and industry standards play a crucial role in driving energy efficiency in manufacturing. Compliance with environmental regulations and adherence to energy efficiency standards can incentivize companies to adopt more sustainable practices. Stricter regulations and industry-wide standards help ensure that manufacturers are held accountable for their environmental impact, promoting continuous improvement in energy efficiency. These initiatives lead to substantial reductions in energy consumption and encourage innovation in energy-efficient technologies.

Battery Chemistry and its Environmental Footprint

Lithium-ion Battery Chemistry: A Deep Dive

Lithium-ion batteries (LIBs) dominate the EV market due to their high energy density and relatively long lifespan. However, the complexity of their chemistry, particularly the use of lithium, cobalt, nickel, and manganese, raises significant environmental concerns throughout the entire production lifecycle. Understanding the intricacies of these chemical processes is critical to evaluating the environmental impact of EV batteries and developing sustainable alternatives.

Raw Material Extraction and Processing

The extraction of raw materials like lithium, cobalt, and nickel often involves environmentally damaging practices, such as open-pit mining. These processes can lead to significant habitat destruction, water contamination, and the release of harmful chemicals into the surrounding environment. Sustainable mining practices, including the use of recycled materials and improved extraction techniques, are crucial to mitigating these environmental impacts.

Furthermore, the processing of these raw materials into battery-grade components necessitates substantial energy consumption and often involves chemical processes that generate pollutants. Optimizing these processes and seeking alternative, less polluting resources is paramount.

Manufacturing Processes and Energy Consumption

The manufacturing of EV batteries, from cell assembly to battery pack integration, consumes significant amounts of energy. The energy source used in these processes significantly impacts the overall carbon footprint of the battery. Switching to renewable energy sources for manufacturing is a crucial step in reducing the environmental impact of battery production. Furthermore, optimizing manufacturing processes to reduce energy consumption and waste generation is essential.

Battery Degradation and End-of-Life Management

Lithium-ion batteries, while offering high performance, degrade over time, impacting their energy storage capacity. Understanding the factors contributing to battery degradation, such as temperature fluctuations, charging/discharging cycles, and material degradation, is essential for optimizing battery performance and extending their lifespan. Proper end-of-life management is critical to preventing the release of hazardous materials into the environment and to recover valuable materials for recycling.

Cobalt and Nickel Supply Chain Issues

The global supply chains for cobalt and nickel, crucial components in many LIB chemistries, often involve complex and opaque processes. This complexity makes it challenging to trace the origin of these materials and assess the environmental and social impacts along the entire supply chain. This lack of transparency necessitates greater traceability and ethical sourcing practices throughout the supply chain to reduce exploitation and environmental damage.

Alternative Battery Chemistries and Materials

Research into alternative battery chemistries, such as solid-state batteries and those using different metallic elements, offers potential solutions to reduce the environmental impact of EV batteries. Solid-state batteries, for instance, may mitigate the reliance on materials with complex and often problematic supply chains. The development of these alternative technologies is crucial to achieving a more sustainable and environmentally friendly future for electric vehicle batteries.

Recycling and Material Recovery

Recycling used EV batteries is essential for recovering valuable materials and reducing the demand for newly extracted resources. Effective recycling processes need to be developed to efficiently recover lithium, cobalt, nickel, and other essential components, minimizing the environmental impact of disposal and maximizing the reuse of valuable materials in new batteries. Investing in advanced recycling technologies is key to a circular economy for battery materials.

Rare earth elements (REEs) are a group of 17 chemically similar metallic elements. Their unique properties make them indispensable in a vast array of modern technologies, from smartphones and electric vehicles to wind turbines and advanced medical equipment. Their importance cannot be overstated, as they form the bedrock of many high-tech industries. Understanding their characteristics and applications is crucial for comprehending the technological advancements shaping our world.

Life Cycle Assessment: Evaluating the Full Impact

Material Extraction and Processing

The initial stages of EV battery production involve extracting raw materials like lithium, cobalt, nickel, and manganese from the earth. This process, while essential, often comes with significant environmental consequences. Mining operations can lead to habitat destruction, soil erosion, and water contamination. Furthermore, the energy-intensive processing of these ores, including refining and purification, contributes considerably to greenhouse gas emissions and resource depletion. Understanding the environmental footprint of these initial steps is crucial for assessing the overall sustainability of EV battery production.

Manufacturing Processes

Once the raw materials are processed, they undergo various manufacturing steps to transform them into battery components. These processes encompass a range of activities, from chemical reactions to the assembly of cells, and each step has its own environmental impact. The energy consumption associated with these processes, particularly the use of electricity and other resources, contributes significantly to the overall carbon footprint. Furthermore, the chemical processes involved can generate hazardous waste that requires proper disposal and management.

Battery Cell Assembly

The assembly of individual battery cells into battery packs is a critical stage in EV battery production. This stage often involves intricate processes that involve handling and manipulating delicate components. The efficiency and precision of these assembly lines directly impact the overall performance of the final battery product. Furthermore, the materials and techniques employed during this phase significantly affect the battery's lifespan and safety characteristics, which in turn influence its environmental impact over its entire service life. Careful consideration of waste generation and resource utilization in this step is essential.

Battery Pack Integration and Testing

After cell assembly, battery packs are integrated and rigorously tested to ensure their performance, safety, and durability. This stage involves various testing procedures and quality control measures to ensure the battery meets the required specifications for vehicle operation. The energy consumption during these tests and the disposal of any faulty or discarded components also need to be accounted for in a comprehensive life cycle assessment. This stage also involves the use of specialized equipment and materials, which have their own environmental impact.

Vehicle Integration and Use

Integrating the battery pack into the electric vehicle (EV) is a crucial step in the life cycle. The transportation and installation of the battery pack within the vehicle must be considered. The use of the EV and its subsequent charging patterns also have a significant impact. Understanding the charging infrastructure and energy source used to power the vehicle is essential for assessing the overall environmental impact, especially when considering the varying sources of electricity generation in different regions.

End-of-Life Management

The eventual end-of-life of the EV battery is a critical aspect of the overall life cycle assessment. Proper recycling and disposal procedures are essential to minimize environmental damage. The presence of hazardous materials in batteries requires careful handling and processing to prevent environmental contamination. The ability to effectively recover and reuse valuable materials from end-of-life batteries is crucial for reducing the overall environmental impact and promoting a circular economy for EV battery components. Efficient recycling strategies are key to minimizing waste and maximizing the recovery of valuable materials.

Transportation and Logistics

The movement of raw materials, components, and finished batteries across the globe plays a significant role in the environmental impact of the entire process. The transportation of these materials and products consumes substantial amounts of energy, which contributes to greenhouse gas emissions. Optimizing transportation routes, utilizing more efficient vehicles, and implementing strategies for reducing the distance traveled are important considerations in minimizing the environmental impact of the supply chain. Careful consideration of the transportation methods and distances involved in the production and distribution of EV batteries is crucial for a comprehensive life cycle assessment.

Recycling and the Circular Economy: A Crucial Future Strategy

Recycling EV Batteries: A Critical Component of the Circular Economy

The rapid growth of electric vehicle (EV) adoption necessitates a robust and sustainable approach to battery management, including recycling. A circular economy model for EV batteries is crucial for mitigating environmental concerns associated with the large-scale production of these vehicles. This approach focuses on recovering valuable materials from end-of-life batteries, thereby reducing reliance on virgin resources and minimizing the environmental footprint of the entire process.

Recycling EV batteries is not just an environmental imperative, it's also an economic opportunity. The process allows for the recovery of critical metals like lithium, cobalt, nickel, and manganese, which are essential components of EV batteries. These recovered materials can be used in the production of new batteries, reducing the demand for mining and processing virgin materials, and creating a closed-loop system.

Challenges in EV Battery Recycling

Despite the potential benefits, significant challenges hinder widespread EV battery recycling. One major hurdle is the complexity of the battery chemistry. Different battery chemistries contain various combinations of materials, and each requires a specific and often complex recycling process. This complexity can make it difficult to develop efficient and cost-effective recycling methods.

Furthermore, the availability of suitable infrastructure and skilled labor is often a limiting factor. Establishing dedicated recycling facilities and training the workforce necessary for this specialized work presents considerable logistical and economic hurdles.

Economic Incentives for Battery Recycling

Government incentives and policies play a critical role in driving the development and implementation of EV battery recycling programs. Financial incentives for manufacturers and recyclers can encourage investment in recycling infrastructure and technology, making the process more economically viable. These incentives can take various forms, including tax credits, subsidies, and grants.

Technological Advancements in Recycling

Technological advancements are steadily improving the efficiency and cost-effectiveness of EV battery recycling. New technologies are being developed to improve the extraction of valuable materials, reduce energy consumption, and minimize waste generation during the process. This continuous innovation is key to making recycling a more sustainable and profitable endeavor.

Materials Recovery and Purification

The successful recycling of EV batteries hinges on the ability to recover and purify the critical materials within. Advanced separation techniques, such as hydrometallurgy and pyrometallurgy, are being investigated to extract valuable metals from the battery components effectively and cost-efficiently. Moreover, the purity of the recovered materials is crucial for their reintroduction into the battery production cycle.

The Role of Collaboration and Partnerships

Collaboration among various stakeholders, including battery manufacturers, recyclers, research institutions, and governments, is essential for the development and implementation of effective EV battery recycling strategies. Partnerships can facilitate knowledge sharing, technology transfer, and resource allocation, accelerating the progress toward a circular economy for EV batteries.

Environmental Impact of EV Battery Production and Recycling

While EV adoption promises a cleaner transportation future, the environmental impact of battery production and recycling must be carefully considered. Minimizing the environmental footprint of both stages is crucial. By prioritizing recycling and developing sustainable production methods, we can mitigate the potential negative consequences associated with the manufacturing of EV batteries.