Bio-Based Plastics for Interior Components

Bio-based plastics are increasingly being used in automotive interiors to reduce reliance on fossil fuels and create more sustainable vehicles. These materials, derived from renewable resources like corn starch or sugarcane, offer a viable alternative to traditional petroleum-based plastics. The use of bio-based plastics in dashboard components, door panels, and trim pieces can significantly lessen the environmental impact of car manufacturing. They often exhibit comparable performance characteristics, making them a practical substitute in various interior applications.

Moreover, the production of bio-based plastics frequently involves fewer harmful emissions compared to conventional methods. This reduction in greenhouse gas emissions is a crucial factor in minimizing the automotive industry's carbon footprint. Bio-based alternatives are also often more readily biodegradable than petroleum-based plastics, leading to a decreased reliance on landfills and contributing to a more circular economy.

Sustainable Alternatives for Exterior Components

Beyond interior applications, bio-based materials are also being explored for exterior components, such as bumpers and exterior trim. These materials can be formulated to meet the stringent durability and performance standards required for automotive use. The development of bio-based composites and resins offers promising avenues for creating Sustainable Alternatives to traditional materials.

The potential for significant reductions in carbon emissions during the manufacturing process is a major driver for this exploration. This is especially crucial for components that are heavily produced, like bumpers or exterior panels, which can have a substantial impact on the overall environmental footprint of a vehicle.

Manufacturing Processes and Challenges

The transition to bio-based materials in automotive manufacturing isn't without its challenges. One significant hurdle is the cost of sourcing and processing renewable resources. The scale of production required for widespread adoption can also pose logistical and economic hurdles. Furthermore, ensuring consistent quality and performance across different batches of bio-based materials is crucial for automotive applications.

However, ongoing research and development are addressing these challenges. Innovations in processing techniques and material formulations are continuously improving the performance and cost-effectiveness of bio-based alternatives. This ongoing effort is crucial for broader adoption and integration into mainstream automotive production.

Future Trends and Market Potential

The future of bio-based materials in the automotive sector looks promising. Growing consumer demand for sustainable products is driving significant investment in research and development. Governments worldwide are also implementing policies and incentives to encourage the adoption of eco-friendly materials, creating a favorable market environment. The market potential is substantial, as manufacturers strive to meet increasingly stringent environmental regulations.

Furthermore, advancements in material science are leading to the development of bio-based polymers with enhanced properties, such as improved strength and durability. This evolution will likely lead to wider applications of bio-based materials across various automotive components, including structural parts in the future.

Exploring Alternative Paint Technologies for Enhanced Sustainability

Exploring Water-Based Paints

Water-based paints are a popular choice for their environmental friendliness and ease of application. They typically contain fewer volatile organic compounds (VOCs) than traditional oil-based paints, making them a more sustainable option. This reduced VOC content translates to a healthier indoor environment, particularly important for families with young children or those with respiratory sensitivities. Water-based paints also tend to dry more quickly, reducing the time spent waiting for the next coat. This makes them practical for projects with tight deadlines. Furthermore, the water-based formula is generally easier to clean up compared to oil-based paints. The use of water as a solvent makes cleaning brushes and tools a quick and simple process.

The variety of water-based paints available is substantial, ranging from acrylics to latex. Each type has its own unique properties, affecting factors like durability, color vibrancy, and resistance to moisture. Understanding the specific characteristics of each type of water-based paint is crucial for selecting the most appropriate option for a given project. This knowledge ensures optimal results and longevity of the finished product.

Investigating Oil-Based Paints

Oil-based paints have been a cornerstone of the painting industry for centuries. Their rich color payoff and exceptional durability are undeniable strengths, making them ideal for exterior applications where resistance to weathering is paramount. The longevity and resilience of oil-based paints are particularly significant when dealing with severe weather conditions or high-traffic areas. However, their slow drying time and strong odor can be significant drawbacks. They also require specialized solvents for cleanup, which can be an added expense and potential environmental concern.

Despite these drawbacks, oil-based paints maintain a dedicated following. Their unmatched durability and rich pigmentation make them a top choice for professionals and DIY enthusiasts alike. The robust nature of oil paints often makes them the preferred option for projects where longevity and resilience are paramount.

Delving into Acrylic Paints

Acrylic paints are a versatile medium, combining the best aspects of both water-based and oil-based paints. They offer excellent color vibrancy and quick drying times, similar to water-based options. The quick drying time of acrylics makes them a popular choice for artists and crafters, allowing for rapid execution of projects and multiple layers. However, they may require more coats to achieve the desired opacity compared to oil-based paints.

Acrylic paints are also known for their ease of use and versatility. They can be applied to a wide range of surfaces, including canvas, wood, and even fabric. The unique characteristics of acrylic paints make them a popular choice for diverse creative projects.

Exploring Specialized Paint Finishes

Beyond the basic categories, specialized paint finishes cater to specific needs and project requirements. These finishes often include features like high gloss, matte, or satin, influencing the appearance and feel of the final product. The choice of finish is crucial for achieving the desired aesthetic and functionality. For instance, high-gloss finishes are ideal for highlighting intricate details, while matte finishes provide a subtle and understated look. Understanding the nuances of each finish is essential for selecting the optimal option for a given project.

Analyzing Environmental Impact

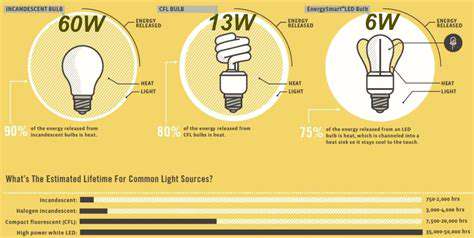

The environmental impact of paint choices is a growing concern. The selection of paints with low VOC content is becoming increasingly important for protecting air quality and reducing the impact on the environment. Considering the environmental impact of paints is essential for sustainable practices and responsible consumption. This is a crucial factor that must be taken into account when selecting paint for any project.

Manufacturers are increasingly developing eco-friendly options with reduced VOC emissions, supporting a healthier environment and contributing to a more sustainable future. Understanding these factors is essential for making informed decisions about the products used in any project.

Comparing Cost and Availability

The cost of paint can vary significantly depending on the type, brand, and quantity. Oil-based paints often come with a higher price tag due to the manufacturing process and the specialized solvents required. Water-based paints, especially acrylics, tend to have a more moderate price point. Availability can also vary depending on the specific type of paint and the retailer. The price and availability should be carefully considered before committing to a particular brand or product. Knowing these factors allows for a more informed decision making process when choosing the perfect paint.

Comparing prices and checking availability across different retailers is crucial to securing the best possible deal. This comparison ensures that the chosen product meets not only aesthetic needs but also budgetary constraints.

The Importance of Recycling and Waste Management in Automotive Paint Processes

Waste Reduction Strategies in Automotive Paint Shops

Automotive paint processes generate significant amounts of waste, ranging from solvents and thinners to scrap materials and contaminated water. Implementing effective waste reduction strategies is crucial for environmental sustainability and cost savings in automotive paint shops. These strategies encompass a variety of approaches, from optimizing paint application techniques to employing innovative recycling methods. Properly managing and minimizing waste throughout the entire process, from initial material selection to final disposal, is critical for minimizing environmental impact and adhering to regulatory standards. Careful planning and execution of waste reduction strategies can lead to substantial cost reductions by minimizing the need to purchase new supplies and reducing disposal fees.

One key strategy involves the careful selection of raw materials and the use of low-VOC (volatile organic compound) paints. This reduces the volume of hazardous waste generated during the painting process. Furthermore, implementing closed-loop systems for solvent recovery and reuse can significantly decrease the environmental footprint. This involves capturing and purifying solvents for reintroduction into the painting process, thereby minimizing the need for virgin material procurement. By adopting these strategies, automotive paint shops can contribute to a greener environment while simultaneously lowering operational costs.

Recycling and Reuse of Automotive Paint Components

Recycling and reuse of materials generated during automotive paint processes are essential for responsible environmental practices. This encompasses the recycling of paint scrap, contaminated water, and various other byproducts. Implementing effective recycling programs can significantly reduce the amount of waste sent to landfills, which is vital for preserving natural resources and minimizing the environmental impact of automotive manufacturing. By prioritizing recycling and reuse initiatives, companies can demonstrate their commitment to sustainable practices and contribute to a healthier planet.

Beyond paint scrap, the recycling of solvents and other chemical components is also crucial. Specialized recycling facilities can process these materials, separating valuable components and recovering usable solvents. This process not only reduces landfill burden but also lowers the reliance on virgin materials, thus decreasing the overall environmental footprint of the automotive industry. These recycling and reuse strategies are not just environmentally sound but also economically viable, as they can lead to substantial cost savings in the long run by reducing the need for constant replenishment of raw materials.

Properly managing and segregating waste streams is crucial for ensuring successful recycling. This includes carefully classifying materials for efficient processing and maximizing the recovery of valuable components. Accurate record-keeping of waste generation and recycling activities is also essential for demonstrating compliance with environmental regulations and for tracking the effectiveness of waste management programs.

The implementation of advanced recycling technologies can further enhance the efficiency and effectiveness of waste management. Investing in such technologies can significantly improve the quality of recycled materials and increase the volume of materials recovered for reuse. These advancements can transform the automotive industry's approach to waste management, making it more sustainable and environmentally friendly.