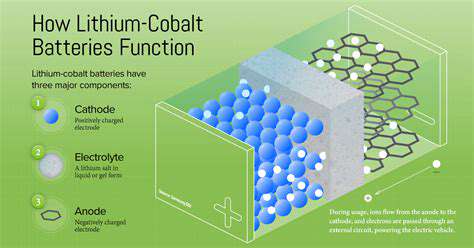

The Crucial Role of Lithium

Lithium, a key component in EV batteries, is a crucial raw material. Its extraction, however, often involves environmentally damaging practices, such as large-scale water consumption and potential contamination of local water sources. Finding sustainable and responsible lithium extraction methods is paramount for the long-term viability of the EV industry and its environmental impact.

The global demand for lithium is escalating rapidly with the increasing adoption of electric vehicles. This surge in demand necessitates a careful consideration of the environmental footprint associated with lithium mining and processing. Sustainable practices that minimize environmental harm are essential to ensure the long-term availability of this critical resource.

Cobalt's Complex Environmental Impact

Cobalt, another essential component in EV batteries, presents a complex environmental dilemma. While crucial for battery performance, its extraction often involves labor practices that raise ethical concerns in some regions. Furthermore, the mining process can contribute to deforestation and soil erosion, impacting local ecosystems.

The search for cobalt alternatives is a significant area of research and development. Finding substitutes or improving existing extraction methods that prioritize sustainability and ethical labor practices is critical to ensure the responsible sourcing of this vital material.

Nickel's Crucial Role and Potential Challenges

Nickel plays a significant role in enhancing the performance and lifespan of EV batteries. However, its mining can also have negative environmental impacts, including habitat destruction and potential water pollution. Sustainable mining practices and the development of recycling infrastructure are essential to mitigate these challenges.

The Importance of Rare Earth Elements

Rare earth elements are critical components in EV batteries, contributing to their efficiency and performance. Unfortunately, the extraction of these elements can be environmentally damaging, often involving the use of large quantities of water and potentially hazardous chemicals. Finding sustainable extraction methods and promoting the use of recycled rare earth elements are crucial steps in addressing this issue.

The global demand for rare earth elements is expected to increase significantly as the EV market expands, prompting the need for responsible sourcing and innovative extraction techniques. This will ensure the long-term availability of these crucial materials while minimizing environmental damage.

Sustainable Mining Practices and Recycling Initiatives

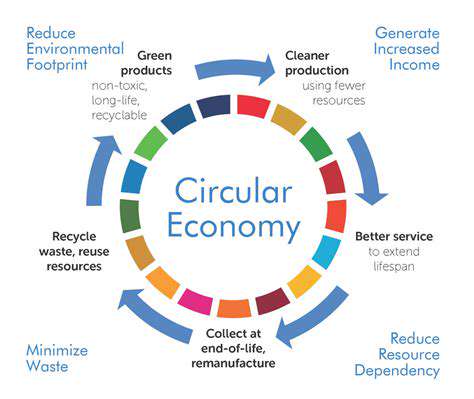

Moving towards a more sustainable future in EV battery production requires a concerted effort on multiple fronts. Firstly, promoting sustainable mining practices is vital. This involves implementing environmentally friendly extraction techniques, minimizing water usage, and ensuring the protection of local ecosystems. Secondly, robust recycling initiatives are essential to recapture valuable materials from end-of-life batteries. This closed-loop system can significantly reduce the demand for raw materials and minimize the environmental impact of battery production.

The Future of Battery Materials: Innovation and Alternatives

The search for innovative battery materials and alternative technologies is a critical area of research and development in the EV industry. Scientists are exploring various options, including materials that require less environmentally damaging extraction methods. This research is essential to address the potential scarcity and sustainability issues associated with current battery components. Furthermore, the development of battery chemistries that reduce or eliminate the need for certain critical raw materials will be crucial.

Developing new battery technologies that are both environmentally friendly and cost-effective is essential for scaling up EV production and ensuring a sustainable future for transportation.

The Lithium-Cobalt Nexus: Ethical Considerations

The Environmental Impact of Lithium Extraction

Lithium extraction, crucial for the production of lithium-ion batteries, is a process with significant environmental consequences. The extraction methods often involve large-scale mining operations, which can lead to habitat destruction and water contamination. These operations can also cause soil erosion and release harmful chemicals into the surrounding environment, impacting local ecosystems and potentially affecting human health. Understanding and mitigating these environmental impacts are essential for sustainable battery production.

Furthermore, the process of refining lithium from ore requires substantial energy consumption. This energy consumption often relies on fossil fuels, adding to the carbon footprint of the entire lithium supply chain. Moving towards renewable energy sources for refining and processing is critical to reducing the environmental burden of lithium production.

Ethical Considerations in Cobalt Sourcing

The cobalt used in lithium-ion batteries is often sourced from conflict zones, raising serious ethical concerns. The mining of cobalt in some regions is associated with human rights abuses, including child labor and exploitative working conditions. Consumers and manufacturers have a responsibility to ensure that the cobalt used in their products is sourced ethically and responsibly, avoiding complicity in these problematic practices.

Transparency and traceability in the cobalt supply chain are vital to address these ethical concerns. Implementing robust auditing mechanisms and promoting ethical sourcing practices throughout the supply chain can help to ensure that cobalt is obtained without compromising human rights or environmental standards.

The Economic Implications of the Lithium-Cobalt Relationship

The interdependence of lithium and cobalt in battery technology has significant economic implications for various industries. The high demand for these materials is driving up their prices, potentially impacting the affordability of electric vehicles and other battery-powered products. This price volatility can create economic instability for companies reliant on these materials for production. Furthermore, ensuring a sustainable supply chain and promoting responsible sourcing can create long-term economic stability and competitiveness.

The global economy benefits from a stable and reliable supply of these essential materials. Diversification of the supply chain and investment in alternative battery technologies are crucial to mitigate price fluctuations and dependence on specific regions. This diversification is vital to ensure future economic stability and resilience.

Technological Advancements and Sustainability

Ongoing research and development in battery technology are vital for mitigating the ethical and environmental concerns surrounding lithium and cobalt. New battery chemistries that require less lithium and cobalt are emerging, offering potential solutions to the supply chain issues and environmental impact. These advancements hold the promise of a more sustainable and ethical future for battery production.

Investment in recycling and reuse technologies for lithium-ion batteries is also crucial. Recycling can significantly reduce the demand for new raw materials, lowering the environmental footprint of the industry and minimizing the impact on resource depletion. Implementing these technologies can contribute to a circular economy for battery materials.

Battery Lifecycle Management: From Cradle to Grave

Understanding the Battery Production Process

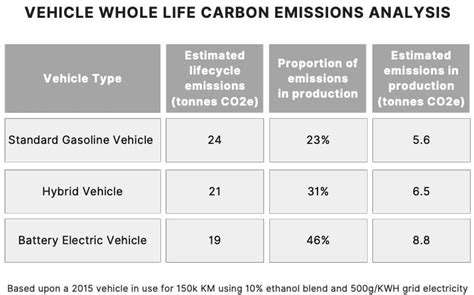

The journey of an EV battery begins long before it powers a vehicle. From the mining of raw materials like lithium, nickel, and cobalt to the complex manufacturing processes involving battery cell assembly, battery pack integration, and quality control, every step contributes to the overall environmental footprint. Understanding these intricate steps is crucial to grasping the lifecycle implications of EV batteries and developing sustainable practices throughout the supply chain.

Raw material sourcing, particularly for critical minerals, often involves significant environmental impacts. The extraction, processing, and transportation of these materials can lead to habitat destruction, water pollution, and greenhouse gas emissions. Minimizing these impacts requires responsible sourcing strategies, focusing on ethical mining practices, and exploring alternative materials to reduce reliance on specific minerals.

Environmental Impact of Battery Manufacturing

The manufacturing of EV batteries isn't without its environmental challenges. High energy consumption during the production process, particularly in the battery cell manufacturing phase, contributes to carbon emissions. Furthermore, the use of various chemicals and solvents in the manufacturing process can lead to water contamination and pose risks to human health if not managed properly. Implementing energy-efficient technologies and adopting sustainable chemical alternatives are crucial to mitigating these impacts.

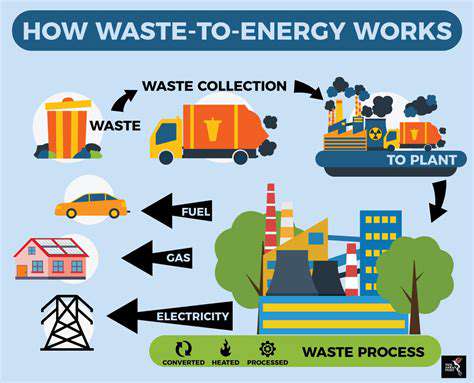

Waste management is another critical aspect. Proper disposal and recycling of hazardous byproducts and materials from battery manufacturing are essential to prevent environmental damage. Developing robust recycling infrastructure and establishing clear guidelines for waste management are vital for a sustainable battery production process.

Battery Pack Integration and Testing

Once individual battery cells are assembled, they are integrated into battery packs. This process involves intricate engineering and quality control measures to ensure safety, performance, and longevity. The design and construction of battery packs must consider factors like thermal management, electrical connectivity, and structural integrity to ensure safe and reliable operation of the battery pack within the vehicle. Rigorous testing protocols are implemented to guarantee the performance and safety of the assembled battery packs.

Battery Degradation and Recycling

The lifespan of an EV battery is finite. Factors like temperature fluctuations, driving habits, and the sheer number of charge-discharge cycles contribute to battery degradation. As batteries age, their performance decreases, requiring eventual replacement. Sustainable battery recycling plays a critical role in recovering valuable materials and minimizing the environmental impact of battery disposal. Recycling facilities need to be established and optimized to properly extract and recover valuable materials from spent batteries.

Life Cycle Assessment and Sustainability Measures

A comprehensive life cycle assessment (LCA) is essential to evaluate the environmental impacts of EV batteries from cradle to grave. LCA examines all stages of the battery's life, from material extraction to end-of-life disposal, to identify areas for improvement and develop sustainable solutions. Integrating LCA principles into the design and manufacturing process of EV batteries is crucial for reducing environmental footprints. This includes exploring alternative materials, optimizing energy consumption, and promoting responsible waste management throughout the battery's lifecycle.