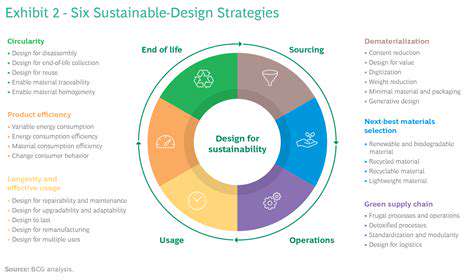

Effective product design often hinges on the ability to easily disassemble and reassemble components. This consideration, often overlooked, can significantly impact future maintenance, repair, and even the overall lifespan of the product. Careful planning during the design phase can lead to substantial cost savings and increased customer satisfaction. It is crucial to anticipate potential future modifications and repairs to ensure the product remains serviceable over its entire lifecycle.

Component Interchangeability

Designing for disassembly necessitates a focus on component interchangeability. This means that identical or compatible parts should be easily replaceable without requiring specialized tools or extensive procedures. This principle ensures that repair processes are streamlined and that replacement parts can be sourced more readily. It also significantly reduces the potential for errors during maintenance, thereby enhancing safety and reliability.

Modular Design Principles

Employing modular design principles allows for the separation of components into independent, self-contained units. This facilitates easier disassembly and assembly, as individual modules can be removed or replaced without affecting other parts of the system. Modular design also allows for greater flexibility in customization and adaptation to future needs. For example, a modular phone case design might allow for the replacement of the screen or battery without replacing the entire case.

Material Selection and Attachment Methods

Choosing appropriate materials and attachment methods plays a crucial role in facilitating disassembly. Materials with inherent ease of separation, such as friction-fit connections or readily separable adhesives, are preferred over complex or permanent bonding agents. Avoid materials that are difficult to separate or require specialized tools for removal, as this will increase the complexity and cost of repair. Using standardized fasteners and connectors will also reduce the need for specialized tools.

Tooling and Accessibility Considerations

Careful consideration of the tools required for disassembly is essential. Designers should ensure that all necessary tools are readily available and that the components are accessible for maintenance and repair. The placement of components should prioritize ease of access to facilitate quick and efficient disassembly. This includes designing for sufficient space around components for tool manipulation. Poor accessibility can lead to costly delays and errors during repair.

Documentation and Training

Clear and comprehensive documentation is vital for guiding disassembly and reassembly procedures. Detailed diagrams, exploded views, and step-by-step instructions will significantly aid technicians in performing repairs. Comprehensive documentation also helps in training personnel on proper maintenance procedures, ensuring consistency and reducing errors. Training materials should be easily accessible and regularly updated to reflect any design changes or modifications. This is absolutely key to ensuring smooth and reliable operation of the product.

Optimizing Recycling and Material Recovery Processes

Improving Collection and Sorting Efficiency

Effective recycling programs hinge on efficient collection and sorting processes. Properly designed collection routes and strategically placed sorting facilities can significantly reduce contamination rates. This, in turn, increases the overall quality of the recycled materials, making them more valuable and easier to process further down the supply chain. Dedicated staff trained in proper sorting techniques and the use of advanced sorting technologies can also greatly improve the efficiency of the process.

Investing in robust infrastructure, such as specialized sorting equipment and improved transportation systems, can dramatically reduce processing costs and ensure that more materials are recovered for reuse. Furthermore, clear communication and education initiatives can empower residents and businesses to participate more actively in the recycling process.

Promoting Material Recovery and Reuse

Recycling programs should prioritize the recovery and reuse of valuable materials. This involves identifying and prioritizing materials with high market demand and strong recycling potential. Implementing programs that encourage the reuse of materials, such as textile recycling or composting initiatives, can significantly reduce the amount of waste sent to landfills. Such programs can also create new economic opportunities by supporting the development of local recycling industries.

Careful material selection and prioritization are crucial for ensuring that the most valuable materials are recovered and reused. This approach not only minimizes environmental impact but also fosters economic sustainability and resource efficiency within the community.

Enhancing Public Awareness and Engagement

Effective recycling programs rely heavily on public awareness and engagement. Clear and concise communication strategies are essential for educating residents about the benefits of recycling and the proper methods for sorting materials. Implementing comprehensive educational campaigns that highlight the environmental and economic advantages of recycling can significantly increase participation rates. This can be achieved through various methods, including community workshops, online resources, and partnerships with schools and local organizations.

Public outreach and engagement initiatives can also help to identify and address any barriers to participation, such as lack of knowledge or access to recycling facilities. By proactively addressing these challenges, recycling programs can foster a culture of sustainability and resourcefulness within the community.

Developing Sustainable Recycling Systems

Long-term success in recycling requires the development of sustainable systems that consider the entire lifecycle of materials. This includes designing products with recyclability in mind, and exploring innovative technologies for material recovery and processing. The integration of advanced technologies, such as advanced sorting equipment, can significantly enhance the efficiency and quality of recycling operations. This will in turn maximize the value of recovered materials.

Ultimately, the goal is to create a closed-loop system where materials are continuously recycled and reused, minimizing waste and maximizing resource efficiency. This approach promotes a circular economy that conserves resources and reduces environmental impact.

Flavor isn't confined to the culinary world; it's present in countless aspects of our daily lives. The aroma of freshly baked bread, the scent of rain after a summer shower, or the taste of a favorite beverage—all evoke specific emotions and memories. Experiencing flavor in its various forms enriches our lives and allows us to connect with the world around us on a deeper level. It's a powerful tool for appreciating the beauty and complexity of life itself.

Rethinking End-of-Life Vehicle Management

Re-evaluating Vehicle Disposal Practices

The current methods of end-of-life vehicle (ELV) management often result in significant environmental hazards. Improper disposal leads to the release of harmful toxins into the air and soil, impacting local ecosystems and human health. This includes the leaching of heavy metals and other pollutants from vehicle components into surrounding environments, potentially contaminating groundwater sources. The scale of this problem is substantial, with a vast number of vehicles reaching the end of their lifespan each year, necessitating a comprehensive re-evaluation of current disposal practices.

Sustainable alternatives to traditional methods are crucial for mitigating these environmental risks. Recycling and repurposing vehicle components can significantly reduce the volume of waste sent to landfills and minimize the demand for raw materials, thereby lowering the overall environmental footprint. Innovative solutions are needed to effectively and economically manage the increasing volume of end-of-life vehicles, minimizing the negative impact on both the environment and human populations.

Exploring Technological Advancements in Recycling

Technological advancements offer promising avenues for improving ELV recycling processes. Advanced separation techniques, such as magnetic sorting and advanced chemical extraction methods, can enhance the recovery of valuable materials like metals, plastics, and rubber. This can increase the overall efficiency of recycling operations, ensuring a higher percentage of materials are recovered and repurposed.

Furthermore, the development of new recycling technologies allows for the recovery of previously unrecoverable materials. For example, innovative techniques for processing complex materials like batteries can significantly reduce the environmental burden associated with their disposal, while simultaneously extracting valuable resources. These advancements are crucial for creating a more sustainable and efficient approach to end-of-life vehicle management.

Promoting Policy Changes and Public Awareness

Effective ELV management requires a multi-pronged approach, encompassing policy changes, public awareness campaigns, and industry collaboration. Government regulations and incentives can encourage the adoption of sustainable disposal practices by manufacturers and consumers. These regulations should mandate the use of environmentally friendly disposal methods and promote the recycling of vehicle components.

Public awareness campaigns can play a crucial role in educating consumers about the importance of responsible vehicle disposal. These campaigns can highlight the environmental benefits of recycling and repurposing vehicle components, thereby motivating individuals to participate in sustainable practices. A collaborative effort between policymakers, industry leaders, and the public is essential for the successful implementation of effective end-of-life vehicle management strategies.