Bio-Based Fabrics: An Overview

Bio-based textiles represent a revolutionary shift from petroleum-derived materials to plant-based alternatives. Unlike conventional synthetics dependent on fossil fuels, these innovative fabrics utilize renewable agricultural resources. The automotive industry's growing interest in these materials reflects broader concerns about petroleum dependency and the environmental consequences of traditional manufacturing processes. When applied to car interiors, these fabrics offer an eco-friendly alternative without sacrificing quality or performance.

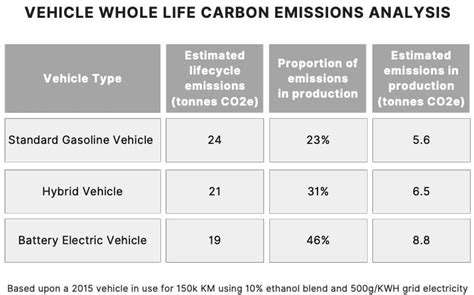

The automotive sector's adoption of bio-based materials isn't simply following a trend—it's responding to fundamental changes in consumer expectations and regulatory requirements. Production of these fabrics typically requires less energy and generates fewer emissions than conventional alternatives, significantly reducing the environmental impact of vehicle manufacturing.

Plant-Based Fiber Innovations

Traditional natural fibers like cotton, flax, and hemp are being reimagined through modern processing techniques. While cotton remains popular, its water-intensive cultivation has prompted development of more sustainable farming methods. Flax, valued for its natural durability, shows particular promise for automotive applications where material strength is essential.

Cellulose-Based Solutions

Plant-derived cellulose is emerging as a game-changing material for sustainable textiles. By transforming wood pulp and agricultural byproducts into high-performance fabrics, manufacturers can significantly reduce reliance on petrochemicals. This approach to eco-conscious material production could revolutionize how automotive interiors are manufactured.

Advanced Manufacturing Techniques

Innovations in textile production are enabling manufacturers to create bio-based fabrics that meet the exacting standards of automotive applications. Modern spinning and weaving technologies allow for precise control over fabric characteristics, while eco-friendly dyeing processes minimize chemical use and water consumption.

Performance Testing and Enhancement

Extensive research is overcoming traditional limitations of natural fibers in automotive applications. Scientists are developing treatments to improve moisture resistance, stain protection, and durability—critical factors for vehicle interiors subjected to heavy daily use.

Overcoming Industry Challenges

While promising, bio-based fabrics still face hurdles including production scalability and cost competitiveness. Future development must focus on creating materials that match the performance of synthetic alternatives while maintaining environmental benefits. Potential solutions include innovative fiber blends and advanced processing methods that could make these fabrics more accessible to mainstream manufacturers.

Market Reception and Growth Potential

Growing environmental awareness among consumers is accelerating demand for sustainable automotive materials. As buyers become more educated about the ecological impact of their purchases, automakers are responding by incorporating bio-based fabrics into their designs. This shift is driving increased investment in material research and development, suggesting strong future growth for sustainable automotive textiles.

The Challenges and Future Outlook for Sustainable Fabrics

Market Transformation Through Sustainability

The textile industry stands at a crossroads as environmental concerns reshape consumer expectations. Today's buyers demand transparency and sustainability throughout the supply chain, forcing brands to fundamentally rethink their material selection and production methods. This isn't a passing fad—it reflects deep societal changes in how people evaluate products and make purchasing decisions.

The environmental consequences of conventional textile manufacturing—from water contamination to excessive carbon emissions—have become impossible to ignore. Consumers now hold companies accountable for their ecological impact, creating strong market incentives for sustainable innovation.

Environmental Costs of Conventional Textiles

Traditional textile production remains one of the world's most polluting industries. Toxic chemical runoff from dyeing processes, excessive water consumption in cotton cultivation, and energy-intensive manufacturing create significant environmental burdens. Perhaps most concerning is the growing crisis of textile waste, with non-biodegradable fabrics accumulating in landfills at alarming rates.

These environmental impacts, combined with concerns about labor practices in global supply chains, have created urgent demand for more responsible textile alternatives across multiple industries.

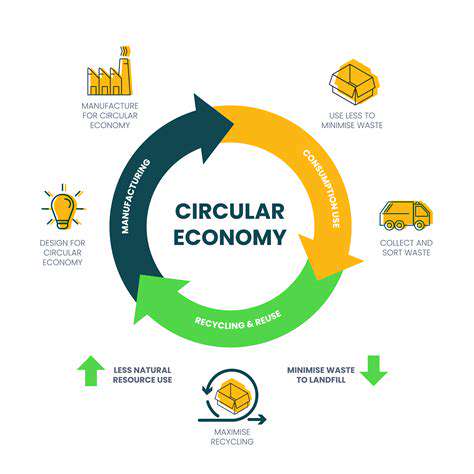

Pioneering Sustainable Material Solutions

Material scientists are making remarkable progress in developing high-performance fabrics from renewable sources. From algae-based fibers to recycled plastic textiles, these innovations promise to dramatically reduce the fashion industry's environmental footprint. Particularly exciting are advances in bio-engineered materials that can potentially replace petroleum-based synthetics without sacrificing performance.

These cutting-edge materials maintain the aesthetic and functional qualities consumers expect while addressing critical environmental concerns—a crucial combination for mainstream adoption.

Barriers to Widespread Adoption

Despite promising innovations, significant challenges hinder the scaling of sustainable textile production. High initial capital requirements, limited manufacturing infrastructure, and complex supply chain logistics present substantial obstacles. Additionally, the lack of universal sustainability standards creates confusion in the marketplace, making it difficult for consumers to identify genuinely eco-friendly products.

The Road Ahead for Sustainable Textiles

The future looks bright for sustainable fabrics as technological advances and shifting consumer preferences create powerful market forces for change. The integration of recycled content, plant-based fibers, and innovative production methods points toward a more sustainable future for the textile industry. As environmental regulations tighten and consumer awareness grows, demand for eco-friendly materials will likely accelerate across all sectors.

Realizing this potential will require close collaboration between governments, manufacturers, and consumers to establish clear standards, incentivize innovation, and build the necessary infrastructure for large-scale sustainable production.