Sealant Quality and Formulation

Sealant Performance Characteristics

The effectiveness of any sealant depends largely on its core performance attributes. These fundamental properties dictate how well the material blocks moisture infiltration, resists environmental stressors, and maintains its integrity over time. Professionals consider multiple factors when evaluating sealants, including bonding strength, flexibility under movement, and resistance to temperature extremes. The material's capacity to withstand UV radiation and chemical exposure often determines its suitability for outdoor applications where durability is paramount.

Modern sealants demonstrate remarkable versatility in their physical properties. Architectural applications particularly benefit from formulations that can accommodate structural movement without cracking or losing adhesion. Tensile characteristics and elongation capacity vary significantly between products, influencing their performance in dynamic situations like bridge joints or high-rise curtain walls. These mechanical properties directly affect how well the sealant maintains its protective barrier under stress.

Sealant Formulation and Ingredients

The chemical composition of sealants represents a careful balance of functional components. Base polymers establish the fundamental characteristics, while various additives fine-tune performance for specific applications. This complex formulation process requires extensive testing to ensure all elements work synergistically to meet demanding performance standards across different environmental conditions.

Silicone-based compounds offer exceptional weather resistance, while polyurethane formulations provide superior abrasion resistance in high-traffic areas. The solvent system affects application properties significantly - fast-evaporating carriers enable quicker setting times, while slower solvents allow extended working periods for complex installations. Manufacturers incorporate specialized additives like fungicides for wet environments or fire retardants for safety-critical applications, demonstrating the versatility possible through precise formulation.

Consistency in manufacturing proves essential for reliable performance. Strict quality control measures ensure batch-to-batch uniformity in viscosity, cure rates, and mechanical properties. Production facilities maintain rigorous environmental controls during manufacturing to prevent variations caused by humidity or temperature fluctuations that could affect the final product's performance characteristics.

Environmental Exposure and Weather Conditions

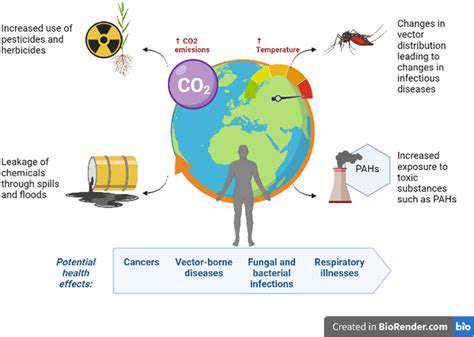

Environmental Factors Influencing Health

Contemporary research continues to reveal the complex relationships between environmental conditions and human physiology. Airborne particulates and chemical contaminants create cumulative health burdens that manifest across multiple biological systems. These environmental stressors contribute to respiratory, cardiovascular, and neurological conditions through various exposure pathways that public health initiatives aim to mitigate.

The Impact of Weather Patterns

Meteorological conditions influence human health through both direct and indirect mechanisms. Temperature extremes strain physiological systems, particularly among vulnerable demographics without adequate climate control. Precipitation patterns affect waterborne disease transmission vectors and influence the geographic distribution of allergens and pathogens. Public health systems must adapt preparedness strategies to address these weather-related health risks effectively.

Air Quality and Respiratory Health

Urban environments present particular challenges for respiratory health due to complex pollution mixtures. Fine particulate matter penetrates deep into lung tissue, while ground-level ozone triggers inflammatory responses. Epidemiological studies consistently demonstrate increased morbidity rates correlating with poor air quality episodes. These findings drive regulatory efforts to reduce emissions from industrial and transportation sources through technological improvements and policy interventions.

Water Quality and Infectious Diseases

Water treatment infrastructure represents a critical defense against microbial pathogens and chemical contaminants. Aging distribution systems and emerging contaminants present ongoing challenges for maintaining water safety standards. Investment in water quality monitoring and treatment technology remains essential for preventing waterborne illness outbreaks. Developing regions particularly benefit from sustainable solutions that provide reliable access to clean water without extensive infrastructure requirements.

Climate Change and Public Health

The accelerating pace of climatic changes introduces novel public health considerations. Shifting disease vector ranges, increasing frequency of extreme weather events, and disruptions to agricultural systems all contribute to emerging health challenges. Heat-related illnesses demonstrate particularly concerning trends, with mortality rates rising disproportionately in urban heat islands. These developments require integrated approaches combining environmental management, urban planning, and healthcare system preparedness.

The Role of Environmental Policies and Regulations

Effective environmental governance requires balancing economic activity with health protection. Regulatory frameworks establish exposure limits for hazardous substances while promoting cleaner production methods. Compliance monitoring and enforcement mechanisms ensure these standards translate into tangible health benefits for communities. International cooperation continues to grow in importance as pollution and climate impacts transcend political boundaries, necessitating coordinated global responses.

Application Techniques and Preparation

Application Techniques for Optimal Results

Surface characteristics dictate appropriate application methodologies, with porous substrates requiring different approaches than non-absorbent materials. The viscosity of the applied material influences tool selection, with thicker formulations benefiting from notched trowels and thinner products applying well through spray systems. Controlled application thickness ensures proper function without wasteful over-application that can lead to curing problems.

Preparation for Effective Application

Surface preparation often determines the ultimate success of any application. Degreasing removes contaminants that could interfere with bonding, while mechanical abrasion improves adhesion on smooth surfaces. Proper substrate conditioning creates the ideal foundation for durable, long-lasting results. This phase frequently consumes more time than the actual application but proves critical for achieving professional-quality outcomes.

Choosing the Right Tools and Materials

Tool selection should consider both the material properties and the working environment. High-volume applications benefit from airless spray systems, while precision work may require specialized brushes or trowels. Material compatibility with application equipment prevents issues like premature curing in spray tips or inadequate mixing in cartridge systems. Proper tool maintenance extends equipment life and ensures consistent application quality throughout projects.

Understanding Product Properties

Comprehensive knowledge of material characteristics prevents common application pitfalls. Cure chemistry influences working time, with moisture-cured systems requiring humidity control and two-component products needing precise mixing ratios. Understanding these parameters allows professionals to optimize application conditions for superior results. Material safety data provides essential information for handling and disposal considerations that maintain workplace safety standards.

Environmental Considerations

Ambient conditions significantly affect application outcomes and material performance. Temperature extremes alter viscosity and cure rates, while humidity impacts moisture-sensitive formulations. Monitoring environmental parameters enables timely adjustments to application techniques that compensate for challenging conditions. Temporary enclosures or climate control measures may prove necessary for critical applications in suboptimal environments.

Safety Precautions and Procedures

Hazard mitigation begins with proper personal protective equipment selection based on material hazards. Respiratory protection proves essential for aerosolized materials, while chemical-resistant gloves prevent dermal exposure. Ventilation requirements vary by product volatility, with some applications demanding supplied-air systems in confined spaces. Emergency response planning and proper waste handling complete comprehensive safety protocols for professional applications.

Troubleshooting and Error Correction

Early problem identification prevents minor issues from becoming major failures. Understanding common application defects like fisheyes, orange peel, or poor adhesion enables quick corrective actions. Surface analysis techniques help diagnose underlying issues that may not be immediately visible. Some imperfections can be remedied through localized repairs, while others may require complete reapplication following proper surface preparation.

Maintenance and Re-application Schedule

Maintenance Considerations

Protective coatings require systematic maintenance to preserve their intended performance characteristics. Cleaning methods must balance effectiveness with coating compatibility, avoiding harsh chemicals that could degrade the protective layer. Regular inspections identify early signs of deterioration before significant damage occurs. Proper documentation of maintenance activities helps establish patterns that inform future care schedules and product selection.

Re-application Timing

Service life predictions consider both product specifications and environmental exposure conditions. Accelerated weathering tests provide laboratory data, while real-world performance observations validate these estimates. Performance indicators like water beading characteristics or color changes signal when reapplication becomes necessary. Some systems incorporate sacrificial layers that extend service life through controlled degradation mechanisms.

Environmental Impact

Regional climate patterns significantly influence coating durability assessments. Coastal environments present salt spray challenges, while desert conditions accelerate UV degradation. Microclimate variations around structures create localized weathering patterns that inform targeted maintenance approaches. These environmental factors guide product selection and maintenance frequency decisions for optimal protection.

Product Specific Guidelines

Manufacturer recommendations provide essential baselines for maintenance planning. Performance warranties often specify required maintenance procedures that maintain coverage validity. Technical datasheets detail expected service life under various exposure conditions based on extensive product testing. Professional applicators combine these guidelines with field experience to develop customized maintenance plans addressing specific project requirements and environmental challenges.