Environmental Impact and Emissions Control

Beyond its mechanical functions, the throttle body plays a surprisingly significant role in environmental protection. By maintaining precise control over the combustion process, it helps minimize the production of harmful emissions. The difference between complete and incomplete combustion often comes down to fractions of a second in fuel delivery timing - timing that the throttle body helps regulate.

Environmental engineers have found that a properly maintained throttle body can reduce hydrocarbon emissions by up to 15% compared to a compromised unit. This becomes particularly important in urban environments where vehicle emissions contribute significantly to air quality issues. Regular inspection and cleaning can maintain this environmental benefit throughout the vehicle's lifespan.

Diagnosing Common Throttle Body Problems

Recognizing throttle body issues early can save vehicle owners significant repair costs. The most common symptoms include:

- Erratic idle speed fluctuations

- Delayed throttle response

- Unexpected stalling

- Reduced fuel economy

These symptoms often develop gradually, making them easy to overlook until they become severe. Many mechanics recommend including throttle body inspection in regular maintenance schedules, especially for vehicles with higher mileage. The cleaning process itself is relatively straightforward but requires specific cleaners that won't damage sensitive components.

Maintenance and Long-Term Care

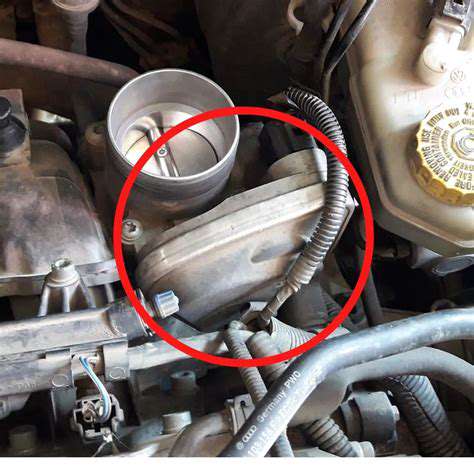

Proper throttle body maintenance involves more than occasional cleaning. The surrounding systems - including the air intake, various sensors, and vacuum lines - all contribute to its proper function. A comprehensive approach should include:

- Visual inspection for carbon buildup

- Testing of electronic components

- Verification of proper mounting and seals

- Calibration checks for electronic throttle systems

Investing in quality maintenance now can prevent expensive repairs later. Many automotive experts suggest throttle body service every 30,000 to 50,000 miles, though this varies by manufacturer and driving conditions.

Troubleshooting Throttle Body Systems

Systematic Diagnostic Approach

When addressing throttle body issues, a methodical approach yields the best results. Start with the simplest potential causes before moving to more complex diagnostics. Professional mechanics typically follow a specific sequence to isolate problems efficiently.

The diagnostic process should always begin with verifying the concern through test drives and data monitoring. Modern scan tools can provide real-time throttle position data that often reveals issues before they become physically apparent. This high-tech approach complements traditional mechanical inspection methods.

Addressing Physical Obstructions

Carbon buildup represents the most common physical issue affecting throttle bodies. This sticky residue accumulates from:

- Blow-by gases from the crankcase ventilation system

- Oil vapors from the PCV system

- Normal combustion byproducts

Removing these deposits requires specialized cleaners that won't damage sensitive throttle components. Avoid using generic carburetor cleaners or abrasive tools that could harm the throttle bore's precise machining. The cleaning process should include careful attention to the throttle plate edges where buildup often interferes with proper sealing.

Electrical System Diagnostics

Modern throttle bodies incorporate multiple electronic components that require specialized testing. The throttle position sensor (TPS) typically provides a variable voltage signal that changes with throttle angle. Testing this signal requires:

- Backprobing the sensor connector

- Monitoring voltage while slowly operating the throttle

- Checking for smooth transitions without voltage spikes or dropouts

Intermittent electrical faults can be particularly challenging to diagnose. These may require monitoring the system over extended periods or during specific driving conditions. Wiring harness issues often manifest as erratic behavior that defies conventional diagnostic patterns.

Advanced System Considerations

With the increasing complexity of modern engine management systems, throttle body issues sometimes stem from problems elsewhere in the system. For example:

| Symptom | Potential Related System |

|---|---|

| Erratic idle | Vacuum leaks, PCV system |

| Throttle lag | Mass airflow sensor, APP sensor |

| Reduced power | Fuel delivery, exhaust restrictions |

This systems approach to diagnostics prevents misdiagnosis and unnecessary repairs. It's often helpful to consult factory service information for specific diagnostic procedures and parameter specifications for each vehicle make and model.