Beyond the Basics: Why Visual Inspection Isn't Enough

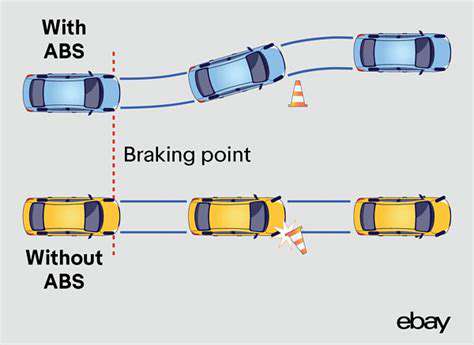

While a quick visual inspection can sometimes identify obvious issues, it often fails to uncover the underlying problems that can lead to costly repairs or even catastrophic failures. Professional assessment goes beyond a superficial glance, employing specialized tools, techniques, and expertise to diagnose potential issues accurately and thoroughly. This proactive approach minimizes downtime and maximizes the lifespan of equipment, preventing costly emergencies.

A thorough inspection by a qualified professional ensures that all critical components are evaluated for wear, tear, and hidden damage. This level of investigation is crucial for maintaining optimal performance and safety, especially in complex systems or those operating under demanding conditions.

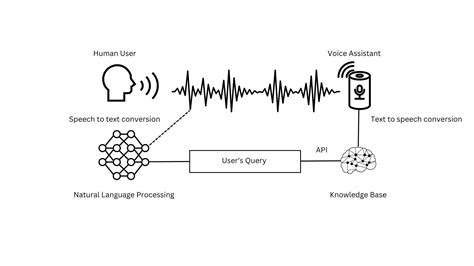

Specialized Tools and Techniques

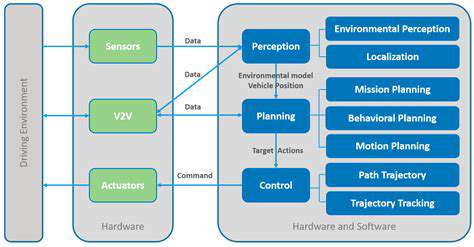

Professional assessment utilizes a range of specialized tools and techniques that go far beyond the naked eye. These tools can include sophisticated diagnostic equipment for electrical systems, pressure gauges for hydraulic components, and advanced acoustic analysis to detect unusual noises that might indicate hidden mechanical problems. By employing these advanced methods, professionals can identify problems early on when they are still manageable and inexpensive to address.

Predictive Maintenance Strategies

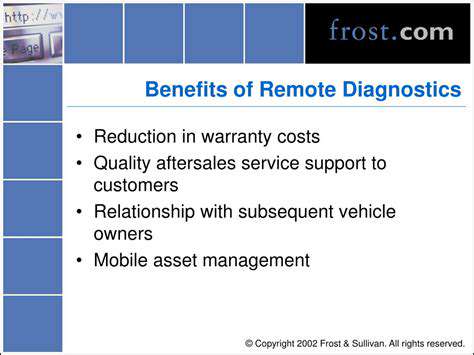

Professional assessment often incorporates predictive maintenance strategies, using data analysis and historical performance records to anticipate potential failures. This proactive approach is far more cost-effective than reactive maintenance, which only addresses problems after they have already occurred. By identifying potential failure points in advance, maintenance can be scheduled before the equipment experiences a breakdown, minimizing downtime and maximizing operational efficiency.

The Role of Expertise and Experience

A professional assessment relies heavily on the experience and expertise of the individuals conducting the evaluation. Years of experience and training equip professionals with the knowledge to interpret subtle signs and symptoms that might be missed by less experienced personnel. This nuanced understanding is critical for identifying complex issues and recommending the most effective course of action.

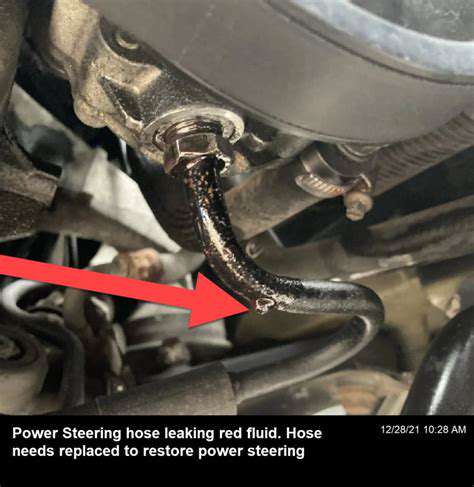

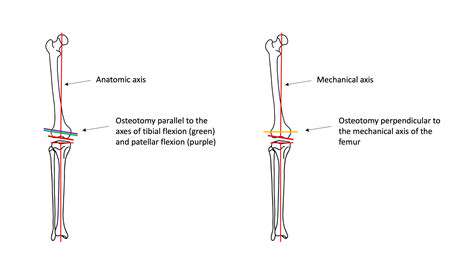

Documenting Findings for Future Reference

A vital aspect of professional assessment is comprehensive documentation. Detailed records of findings, including photos, diagrams, and data analysis reports, provide a valuable historical record for future reference. This documentation is crucial for tracking maintenance history, identifying trends, and ensuring that preventive measures are implemented effectively. This information also allows for better communication between maintenance teams and decision-makers.

Cost-Benefit Analysis and Prioritization

Professional assessment goes beyond simply identifying problems; it also helps to prioritize repairs and maintenance based on a cost-benefit analysis. This analysis considers the potential cost of repairs versus the impact of downtime or potential safety hazards. By strategically prioritizing maintenance tasks, organizations can allocate resources effectively and maximize the return on investment from their maintenance programs.

Safety Considerations and Compliance

Professional assessments are crucial for ensuring safety compliance by identifying potential hazards and recommending appropriate mitigation strategies. This proactive approach helps to prevent accidents and injuries by addressing potential safety risks before they escalate. Compliance with relevant industry regulations and safety standards is paramount in maintaining a safe and productive work environment.

Proactive Maintenance: Preventing Brake Caliper Failure

Planning and Scheduling

Proactive maintenance relies heavily on a well-defined schedule. This schedule should consider the specific needs of each piece of equipment, factoring in its age, usage patterns, and manufacturer recommendations. Establishing a robust maintenance schedule is crucial for anticipating potential issues and preventing costly breakdowns. A proactive approach demands more than just reacting to problems; it requires a proactive mindset in anticipating and addressing potential failures before they occur.

Careful planning involves identifying critical equipment and developing a detailed maintenance checklist for each item. This checklist should outline the specific tasks to be performed, the frequency of those tasks, and the personnel responsible for completing them. This systematic approach ensures that nothing is overlooked and that all necessary maintenance is performed on time.

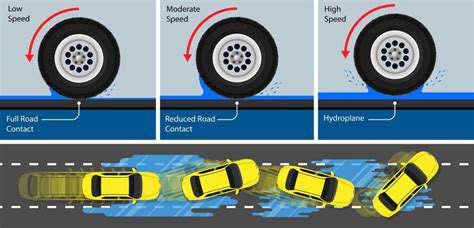

Equipment Monitoring and Diagnostics

Implementing robust monitoring systems is a cornerstone of proactive maintenance. These systems can range from simple visual inspections to sophisticated sensor-based technologies that provide real-time data on equipment performance. By continuously monitoring equipment, potential issues can be detected early, allowing for preventative action before they escalate into major problems. Early detection of issues significantly reduces the likelihood of costly breakdowns and downtime.

Using diagnostic tools, technicians can identify subtle changes in equipment behavior that might indicate impending problems. This allows for timely intervention, minimizing the risk of equipment failure and ensuring optimal performance.

Preventive Maintenance Procedures

Preventive maintenance procedures encompass a wide range of activities designed to maintain equipment in optimal working condition. These procedures often involve cleaning, lubrication, inspection, and adjustments to ensure that equipment components are functioning correctly. These procedures help to extend the lifespan of equipment and reduce the likelihood of unexpected breakdowns.

Regular maintenance procedures often include tasks like lubrication of moving parts, cleaning of critical components, and visual inspections for any signs of wear and tear. These seemingly small tasks can significantly contribute to the overall reliability and longevity of the equipment, thus saving on potential repair costs in the long run.

Employee Training and Skill Development

A critical element of proactive maintenance is ensuring that personnel are adequately trained and equipped to perform the required tasks. Investing in employee training programs that focus on the proper use of equipment, maintenance procedures, and troubleshooting techniques is essential. A skilled workforce is a key component in implementing a successful proactive maintenance strategy. This ensures that any potential issues are handled correctly and efficiently.

Effective training programs should cover the specific maintenance procedures for different types of equipment and how to interpret monitoring data. This will allow employees to identify potential problems early and take the necessary action to prevent more significant issues. Continuous professional development is essential for maintaining a highly capable and adaptable maintenance team.