Bio-based polymers are derived from renewable resources like corn starch, sugarcane, and algae, offering a compelling alternative to traditional petroleum-based plastics. These materials possess a unique advantage in reducing reliance on finite resources and lessening the environmental footprint of the automotive industry. The production process often involves fewer harmful chemicals and significantly lower greenhouse gas emissions compared to conventional plastics, making them a crucial component in the transition to a more sustainable future for car interiors.

The inherent properties of bio-based polymers can be tailored to meet specific needs. For example, some types might excel in strength and durability, suitable for structural components, while others might be ideal for softer, more tactile materials used in upholstery. This versatility is vital in creating a comprehensive range of sustainable options for car interiors, from the hard plastics that form the dashboard to the soft textures of seats and door panels.

Sustainable Sourcing and Production Practices

Sustainable sourcing of raw materials is critical for the long-term viability of bio-based fabrics. This necessitates a focus on responsible farming practices that minimize environmental impact, protect biodiversity, and ensure fair labor standards throughout the supply chain. Transparency and traceability are essential in ensuring that the materials used in car interiors are truly sustainable, from the agricultural field to the manufacturing plant.

Efficient production processes are equally important. Minimizing water usage, optimizing energy consumption, and reducing waste generation are crucial steps in creating a truly sustainable bio-based manufacturing model. These practices contribute to lower environmental impact throughout the entire lifecycle of the fabric, from its initial creation to its eventual end-of-life management.

Performance and Durability of Bio-Based Fabrics

A key consideration for automotive applications is the performance and durability of bio-based fabrics. Bio-based polymers are increasingly demonstrating comparable strength and resilience to traditional plastics, making them viable options for a wide range of interior components. Ongoing research and development are continuously improving these properties, leading to more robust and reliable materials suitable for the demanding conditions inside a vehicle.

The ability of bio-based materials to resist wear and tear, maintain their form, and retain their aesthetic appeal over time is critical for automotive applications. Durability testing and rigorous quality control measures are essential to ensure the longevity of these materials and the overall satisfaction of car owners.

Environmental Impact and Lifecycle Assessment

The environmental impact of bio-based fabrics extends beyond the production process. A comprehensive lifecycle assessment (LCA) is crucial for evaluating the overall environmental footprint of these materials, considering factors like the energy required for production, transportation, and disposal. This holistic approach helps identify areas for improvement and optimization to maximize sustainability throughout the entire product lifecycle.

Comparing the environmental performance of bio-based materials to traditional petroleum-based alternatives is vital for demonstrating their positive impact. Clear data and transparent reporting are essential for fostering public trust and encouraging the wider adoption of sustainable materials in the automotive industry.

Recycled and Upcycled Materials: Giving New Life to Old Textiles

Sustainable Practices in Fashion

The fashion industry is a significant contributor to environmental pollution, largely due to the vast quantities of textile waste generated each year. Using recycled and upcycled materials offers a crucial pathway towards a more sustainable future in the industry. This approach not only reduces textile waste but also minimizes the demand for virgin resources, thereby lowering the industry's carbon footprint and promoting resource conservation.

Implementing sustainable practices in fashion design and manufacturing is becoming increasingly important. Consumers are becoming more aware of the environmental impact of their purchasing decisions, and brands are responding by incorporating recycled and upcycled materials into their collections. This shift towards sustainability is not only environmentally responsible but also presents a significant opportunity for innovation and creativity in fashion design.

The Benefits of Recycling and Upcycling

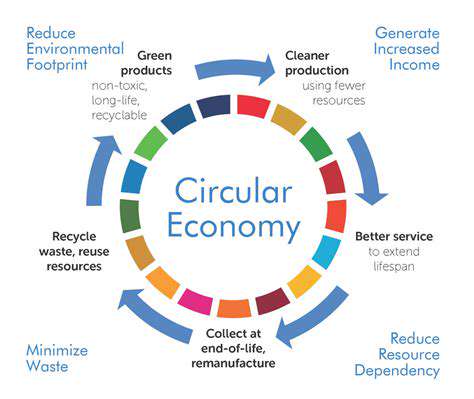

Recycling and upcycling materials provide a multitude of benefits beyond environmental sustainability. These methods help to create a more circular economy, where materials are reused and repurposed instead of being discarded. This reduces the need for extracting new resources, minimizing the environmental impact associated with mining and manufacturing.

Furthermore, the use of recycled and upcycled materials can lead to cost savings for businesses. The lower cost of these materials can be passed on to consumers, making sustainable fashion more accessible. Also, the unique characteristics of these materials can inspire new and innovative designs, pushing the boundaries of fashion creativity.

Innovative Design with Recycled Materials

The use of recycled materials in fashion design has opened up exciting new possibilities for creativity. Designers are exploring innovative ways to transform discarded textiles and other materials into stunning garments. This process often involves intricate techniques and a deep understanding of material science.

By repurposing existing materials, designers can create unique and eye-catching garments that stand out from the mass-produced items found in conventional fashion. Designers can also incorporate recycled materials into the entire design process, from the initial concept to the final product.

The Future of Sustainable Fashion

The growing awareness of environmental issues is driving a significant shift towards sustainable fashion. Consumers are increasingly seeking out brands that prioritize sustainability in their operations, and this demand is pushing designers and manufacturers to innovate and adopt more sustainable practices.

The future of fashion lies in the integration of recycled and upcycled materials into the core of the industry. This will not only minimize the environmental impact of fashion but also create new economic opportunities and foster a more circular economy.

Advanced Composites and Innovative Fiber Technologies: Pushing the Boundaries of Sustainability

Advanced Polymer Composites for Sustainable Materials

Polymer composites are revolutionizing various industries by offering lightweight, high-strength materials with exceptional performance characteristics. These advanced materials, often incorporating innovative fibers like carbon fiber, aramid, or basalt, are crucial for building lighter and more efficient vehicles, creating stronger and more durable infrastructure components, and developing high-performance consumer goods. The inherent recyclability of certain polymer matrices is also a key driver in the pursuit of sustainable solutions, allowing for the creation of a circular economy.

The development of new polymer matrices, coupled with advancements in fiber manufacturing processes, leads to significant improvements in material properties. These improvements include enhanced tensile strength, superior impact resistance, and reduced weight, ultimately impacting the environmental footprint of products and processes across diverse sectors. This evolution of composite materials is paving the way for a more sustainable future.

Innovative Fiber Manufacturing Processes: Enhancing Performance and Efficiency

The performance and sustainability of composite materials are intrinsically linked to the quality and characteristics of the fibers used. Advanced manufacturing processes, such as high-temperature spinning and specialized drawing techniques, are crucial for producing fibers with exceptional strength-to-weight ratios. These innovations allow for the creation of finer, stronger fibers, leading to lighter and more efficient composite structures.

Furthermore, the development of novel fiber architectures, like those incorporating hierarchical structures or tailored surface functionalities, is expanding the potential applications of composite materials. This includes improving bonding, enhancing mechanical properties, and even creating self-healing materials. These advanced manufacturing processes are vital in the pursuit of more sustainable and high-performance materials.

Sustainable Sourcing and Recycling of Composite Materials

The environmental impact of composite materials extends beyond the material itself to encompass the entire lifecycle, including sourcing, manufacturing, and end-of-life management. Sustainable sourcing practices, focusing on responsible sourcing of raw materials and minimizing environmental impact throughout the supply chain, are becoming increasingly important. This includes incorporating recycled materials into the composite matrix, reducing the reliance on virgin resources, and minimizing waste generation during manufacturing.

Recycling and reuse strategies for composite materials are also crucial for a circular economy. Developing effective methods for separating and reclaiming fibers and matrices from end-of-life products is essential for maximizing resource utilization and minimizing environmental impact. The advancement in these recycling and reuse strategies directly contributes to the sustainability and circularity of the composite material sector.

Applications Across Diverse Industries: Driving Innovation and Growth

The applications of advanced composites and innovative fiber technologies span a wide range of industries, driving innovation and growth. From aerospace and automotive sectors, where lightweight and high-performance materials are paramount, to construction and consumer products, where durability and sustainability are key considerations, the use of these technologies is revolutionizing various sectors. The development of new composite materials is also paving the way for the creation of customized solutions tailored to specific performance needs.

The integration of these technologies within industries like energy, healthcare, and electronics is further expanding the potential applications of advanced composites and innovative fiber technologies. This multifaceted approach ensures that the benefits of these innovations are felt across a broad spectrum of sectors, ultimately propelling progress toward a more sustainable future.