The environmental impact of improper battery disposal is substantial. Hazardous materials, like heavy metals, are released into the environment if batteries are not recycled correctly. This poses a threat to both human health and the delicate balance of ecosystems. Furthermore, the finite nature of many essential battery components necessitates a closed-loop recycling system to ensure the long-term sustainability of the EV industry. Ignoring this challenge will ultimately hinder the progress and potential of the EV revolution.

Technological Advancements Driving Recycling Efficiency

Fortunately, technological advancements are paving the way for more efficient and effective EV battery recycling processes. Innovations in chemical extraction techniques are enabling the recovery of valuable metals, like lithium, nickel, and cobalt, from spent batteries. These advancements not only minimize environmental impact but also contribute to the circular economy by recovering valuable resources for reuse in new batteries. This technological progress is crucial for reducing the reliance on primary mining and promoting sustainable resource management.

Sophisticated sorting and separation technologies are also emerging, allowing for the precise categorization of battery components. This precision helps to maximize the recovery of valuable materials and minimize waste. These advanced separation techniques are key to improving the overall efficiency of recycling operations and ensuring that the process is environmentally sound.

Economic Incentives and Policy Support for EV Battery Recycling

The economic benefits of EV battery recycling are significant, extending beyond simply environmental considerations. The recovery of valuable metals can generate substantial revenue streams, creating economic opportunities for recycling facilities and related industries. Moreover, the development of a robust recycling infrastructure can foster job creation and stimulate economic growth in regions focused on EV production and adoption.

Government policies play a critical role in encouraging and supporting EV battery recycling initiatives. Incentives, such as tax credits or subsidies for recycling facilities, can significantly stimulate investment in this crucial area. Furthermore, regulatory frameworks that mandate the proper disposal and recycling of EV batteries are essential for ensuring environmental protection and resource conservation. These policies are vital in fostering a market-driven approach to EV battery recycling.

The Future of EV Battery Recycling: A Collaborative Approach

The future of EV battery recycling hinges on a collaborative approach involving automakers, battery manufacturers, recycling facilities, and policymakers. Open communication and knowledge sharing are essential for developing standardized recycling procedures and ensuring the optimal utilization of resources. By working together, stakeholders can create a framework that promotes sustainable practices and minimizes the environmental impact of EV battery production and disposal.

Partnerships between industry players and research institutions are crucial for driving innovation in EV battery recycling. Collaborative research projects can lead to breakthroughs in extraction techniques and material recovery methods, ultimately optimizing the overall process. This collaborative approach is fundamental to the long-term success of the EV industry and its positive environmental impact.

Pyrometallurgical Processes: Melting Away the Challenges

Introduction to Pyrometallurgical Melting

Pyrometallurgical processes, encompassing a broad spectrum of metallurgical operations, are crucial for extracting valuable metals from ores and refining them. A key component of these processes is melting, which involves heating materials to a high enough temperature to achieve a liquid state. This liquid state allows for separation of impurities and facilitates the extraction of the desired metal components. Understanding the principles of pyrometallurgical melting is essential for optimizing the efficiency and effectiveness of these operations.

Melting is a fundamental step in various pyrometallurgical processes, from smelting to refining. The specific techniques and conditions used depend heavily on the type of ore being processed and the desired metal product. Understanding the chemical reactions and physical transformations that occur during melting is crucial for achieving the desired outcome.

Melting Techniques and Applications

Various techniques are employed for pyrometallurgical melting, including shaft furnaces, blast furnaces, and electric arc furnaces. Each technique has its own advantages and disadvantages in terms of energy efficiency, product quality, and environmental impact. The choice of technique is often dictated by factors such as the type of ore, the desired metal, and the scale of the operation.

These techniques find applications in a wide range of industries, including ferrous and non-ferrous metallurgy, and are crucial in the production of steel, copper, and aluminum. Each application necessitates specific adjustments to the melting process to ensure optimal results.

Chemical Reactions During Melting

During pyrometallurgical melting, various chemical reactions take place between the ore components, fluxes, and other materials added to the furnace. These reactions are crucial for the separation of metals from impurities. Understanding the kinetics and thermodynamics of these reactions is essential for controlling the process and optimizing the yield of the desired metal.

Factors Affecting Melting Performance

Several factors influence the performance of pyrometallurgical melting processes. These include the composition of the ore, the type of flux used, the furnace temperature, and the residence time of the materials within the furnace. Optimizing these factors is essential for achieving high-quality metal products and reducing energy consumption. Careful control of these factors is critical for cost-effective and environmentally responsible operations.

The presence of impurities in the ore can significantly affect the melting process, impacting efficiency and product quality. Strategies to mitigate these impacts are crucial for successful operations.

Energy Consumption and Environmental Considerations

Pyrometallurgical melting processes are often energy-intensive. The selection of energy sources and the implementation of energy-saving technologies are vital for the economic viability and sustainability of these operations. Careful consideration of the environmental impact of these processes, including emissions and waste generation, is crucial for responsible industrial practices.

Safety Precautions in Pyrometallurgical Melting

Pyrometallurgical melting operations involve high temperatures and potentially hazardous materials. Implementing appropriate safety measures, such as proper ventilation, protective equipment, and emergency procedures, is essential for preventing accidents and ensuring the well-being of workers. Adhering to strict safety protocols is critical for maintaining a safe working environment. Regular maintenance and inspections are also crucial for preventing equipment failures and ensuring the safety of personnel.

The Future of EV Battery Recycling: A Holistic Approach for Sustainable Solutions

The Growing Need for Battery Recycling

The rapid adoption of electric vehicles (EVs) is revolutionizing transportation, but it also presents a significant challenge: the disposal and recycling of EV batteries. These batteries, containing valuable metals like lithium, cobalt, nickel, and manganese, are complex and require specialized handling to prevent environmental contamination and maximize resource recovery. The sheer volume of batteries projected to enter the waste stream in the coming decades necessitates a robust and sustainable recycling infrastructure.

Currently, many EV batteries are either landfilled or disposed of in less-than-ideal ways, leading to potential environmental hazards. This not only wastes valuable resources but also raises concerns about the long-term impact on ecosystems and human health. Addressing this growing problem requires a holistic approach that prioritizes sustainability and resource efficiency.

Innovative Recycling Technologies

Several innovative technologies are emerging to enhance the efficiency and effectiveness of EV battery recycling. These include hydrometallurgical processes, which use chemical solutions to extract valuable metals; pyrometallurgical methods, employing high temperatures to separate materials; and mechanical processes, which focus on physically separating components. Each method presents unique advantages and challenges, and the optimal approach may vary depending on the specific battery chemistry and desired metal recovery.

Research and development efforts are focusing on improving the extraction yields of critical metals, reducing energy consumption, and minimizing environmental impact. This continuous advancement in technology is crucial for establishing a viable and economically sustainable battery recycling industry.

Economic Incentives and Policy Support

To incentivize the adoption of battery recycling, governments and industries need to collaborate on creating supportive policies and economic incentives. Financial incentives for manufacturers and recyclers could encourage the development and implementation of advanced recycling technologies. Clear regulations on battery disposal and recycling can help ensure responsible handling and minimize environmental risks.

Establishing robust recycling infrastructure and providing clear guidelines for material handling and transportation are vital for successful implementation. These measures will not only promote sustainability but also create new job opportunities in the growing green economy.

Material Recovery and Purification

Efficient material recovery and purification are essential steps in the battery recycling process. Advanced techniques like solvent extraction and ion exchange can be used to separate the valuable metals from the battery components, ensuring high-purity metal products. This will enable the production of high-quality recycled materials, suitable for use in new EV batteries or other applications.

Furthermore, the development of standardized processes for material characterization and quality control is critical to ensure the reliability and consistency of recycled materials. This will enhance the trust and acceptance of recycled materials within the supply chain.

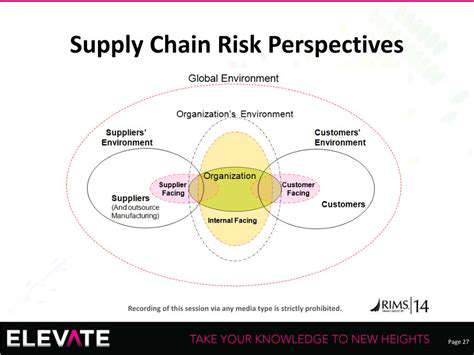

Sustainable Supply Chains and Material Sourcing

Establishing sustainable supply chains for battery recycling is crucial for ensuring a reliable and consistent flow of recycled materials. Collaboration between manufacturers, recyclers, and policymakers is essential to create transparent and ethical supply chains. This collaboration will help ensure that raw materials are sourced responsibly and that the recycled materials are used in a sustainable manner.

Community Engagement and Education

Public awareness campaigns and educational programs can play a vital role in fostering community support for battery recycling initiatives. Educating the public about the importance of responsible battery disposal, the environmental benefits of recycling, and the potential of circular economy models can foster a culture of sustainability. Community engagement efforts can help build trust and encourage participation in recycling programs, contributing to the success of a holistic approach.

The Role of Research and Development

Continued research and development in battery recycling technologies are paramount for achieving a truly sustainable future for EV batteries. Innovations in material separation, energy efficiency, and cost reduction will be crucial for making recycling economically viable. Ongoing research into new battery chemistries and designs can also help to optimize the recycling process for future generations of batteries.

Collaboration between academic institutions, research organizations, and industry stakeholders is essential to drive breakthroughs in battery recycling technology, ensuring that the transition to electric mobility is environmentally responsible and resource efficient.