Improving Building Envelope and HVAC Systems

Improving Building Envelope Performance

A crucial aspect of enhancing building efficiency is optimizing the building envelope. This involves meticulous attention to the structural components that separate the interior from the exterior environment. By addressing thermal bridging, air leakage, and moisture intrusion, building owners can significantly reduce energy consumption. Proper insulation, sealing, and weatherstripping are key elements in minimizing heat transfer, improving indoor comfort, and reducing energy bills.

Careful consideration of materials and their properties is essential. Selecting high-performance insulation, air-tight windows and doors, and water-resistant cladding are vital for long-term building performance. This not only lowers energy costs but also enhances the overall lifespan and durability of the structure. Regular inspections and maintenance of the building envelope are paramount for identifying and rectifying any issues that might arise, ensuring that the building maintains its optimal performance over time.

Optimizing HVAC Systems

High-efficiency heating, ventilation, and air conditioning (HVAC) systems play a significant role in maintaining a comfortable and healthy indoor environment while minimizing energy waste. Upgrading existing systems to incorporate energy-efficient components, like variable-speed drives and heat recovery ventilators, can lead to substantial reductions in energy consumption. This can involve replacing older, less efficient equipment with modern, high-performance alternatives.

Implementing smart building controls and automation is another crucial step. These systems allow for optimized operation of HVAC equipment based on real-time conditions, further minimizing energy usage. Continuous monitoring and adjustments to HVAC parameters based on occupancy and weather patterns are essential for achieving optimal energy efficiency.

Integrating Renewable Energy Sources

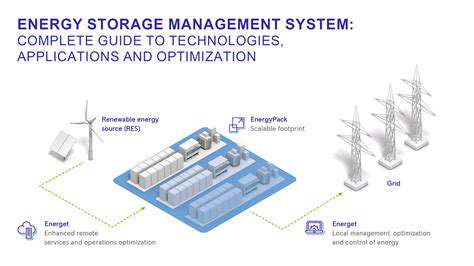

Incorporating renewable energy sources into the building's design and operation can significantly reduce reliance on traditional energy grids. The installation of solar panels, geothermal systems, or wind turbines can provide a substantial portion of the building's energy needs, reducing overall environmental impact. This approach not only lowers energy costs but also contributes to a more sustainable building practice.

Careful consideration of the building's location and potential for renewable energy harvesting is necessary to maximize the benefits. This involves evaluating solar irradiance, wind patterns, and geothermal potential to determine the most effective and efficient renewable energy solutions for the specific site. Integrating these systems seamlessly into the building's infrastructure is crucial for maximizing their effectiveness and minimizing disruption to existing operations.

Implementing Building Management Systems (BMS)

Implementing advanced building management systems (BMS) provides comprehensive control and monitoring of building functions. These systems collect real-time data on various parameters, including energy consumption, temperature, and occupancy, allowing for proactive adjustments and optimized resource allocation. By centralizing data, BMS facilitates precise control over lighting, HVAC, and other systems, leading to significant energy savings.

The ability to remotely monitor and control building systems is a key benefit. This allows for quick responses to issues, reducing downtime and maintaining optimal comfort levels. Furthermore, BMS provides valuable historical data, enabling analysis of energy consumption patterns and identification of areas for improvement in building operations.

Monitoring, Measurement, and Continuous Improvement

Monitoring Energy Consumption

A crucial aspect of achieving energy efficiency in automotive design is the meticulous monitoring of energy consumption throughout the vehicle's lifecycle. This involves tracking fuel efficiency during various driving conditions, from city commutes to highway cruising, and analyzing power consumption in different vehicle systems. Detailed data collection on energy usage allows engineers to pinpoint areas where energy is being wasted, enabling targeted improvements and the identification of inefficiencies in the engine, transmission, and other components. Data analysis is essential to understand the trends and patterns that affect energy consumption, enabling the development of optimized solutions.

Advanced sensors and telemetry systems play a vital role in gathering real-time data on energy consumption. These systems allow for continuous monitoring of power draw, fuel consumption rates, and other relevant parameters. This constant stream of information enables proactive identification of anomalies and potential issues, ultimately leading to more efficient operation and reduced fuel consumption. Furthermore, the ability to collect data across various driving conditions, such as different road surfaces and weather patterns, allows for comprehensive analysis of energy consumption behavior.

Measuring Performance Metrics

Implementing robust performance measurement metrics is critical to evaluate the effectiveness of energy efficiency initiatives. Key performance indicators (KPIs) must be clearly defined and consistently tracked, providing quantifiable data on energy savings achieved by implementing new technologies and design improvements. These metrics should encompass various aspects, including fuel economy, powertrain efficiency, and emissions reduction.

For instance, measuring fuel economy under standardized test conditions, along with real-world driving conditions, allows for a comprehensive evaluation of the vehicle's efficiency. Furthermore, comparing the energy consumption of different vehicle designs or configurations allows engineers to identify and implement the most energy-efficient solutions. This quantitative approach facilitates informed decision-making and ensures that energy efficiency initiatives are producing demonstrable results.

Continuous Improvement Processes

Establishing a culture of continuous improvement is essential for long-term energy efficiency gains in the automotive industry. This requires a systematic approach to identifying opportunities for enhancement, implementing changes, and evaluating their impact. Regular reviews and analyses of performance data are crucial to identifying areas for optimization and ensuring that energy efficiency improvements are sustained over time.

Implementing lean manufacturing principles and Six Sigma methodologies, combined with the use of data analytics, can drive continuous improvement. This approach ensures that the entire design and manufacturing process is optimized for energy efficiency. Furthermore, fostering a collaborative environment where engineers, designers, and manufacturers work together to identify and implement improvements is crucial for success. This collaborative environment encourages creativity and innovation, leading to more effective and sustainable solutions for enhanced energy efficiency in automotive design.

Integration of Advanced Technologies

The integration of advanced technologies plays a pivotal role in achieving significant improvements in energy efficiency. This includes incorporating advanced materials, such as lightweight alloys, to reduce vehicle weight and improve fuel efficiency. Employing advanced engine technologies, like hybrid or electric powertrains, and incorporating smart systems for energy management can dramatically reduce fuel consumption and emissions.

Additionally, utilizing sophisticated software and algorithms for optimal energy management systems, integrated with advanced sensors and actuators, can further enhance energy efficiency. This approach allows for real-time adjustments to vehicle systems based on various driving conditions, ensuring optimal performance and energy savings. The combination of these technological advancements and sophisticated systems creates a synergy that yields substantial improvements in energy efficiency across the entire automotive manufacturing and operational spectrum.