Quantifying the Return on Investment (ROI) of Energy Efficiency Measures

Understanding the Importance of ROI

Quantifying the return on investment (ROI) of energy efficiency measures is crucial for justifying the upfront costs and demonstrating the long-term financial benefits. A well-defined ROI calculation allows businesses and homeowners to make informed decisions about energy efficiency upgrades, aligning them with strategic financial goals. This analysis is essential for evaluating the viability of different projects and ensuring that the investments are worthwhile in terms of both cost savings and overall profitability. Understanding the intricacies of ROI calculation enables effective resource allocation and promotes sustainable practices.

A strong understanding of ROI helps identify projects with the highest potential for financial return, leading to a more efficient allocation of resources. Properly calculated ROI can also serve as a valuable tool for attracting investors and securing funding for energy efficiency initiatives, as it demonstrates a clear path to profitability.

Calculating Simple ROI

Calculating the simple ROI for energy efficiency projects typically involves dividing the total savings generated by the initial investment cost. For example, if a building upgrade saves $5,000 annually in energy costs and the installation cost was $10,000, the simple ROI would be 50% (calculated as $5,000 / $10,000). This straightforward calculation provides a basic understanding of the project's profitability but doesn't account for the time value of money.

Considering the Time Value of Money

A more comprehensive approach to calculating ROI involves considering the time value of money, recognizing that a dollar saved today is worth more than a dollar saved in the future. This requires using more sophisticated methods like Net Present Value (NPV) or Internal Rate of Return (IRR). These methods incorporate the concept of discounting future savings back to their present value, providing a more accurate reflection of the project's true profitability.

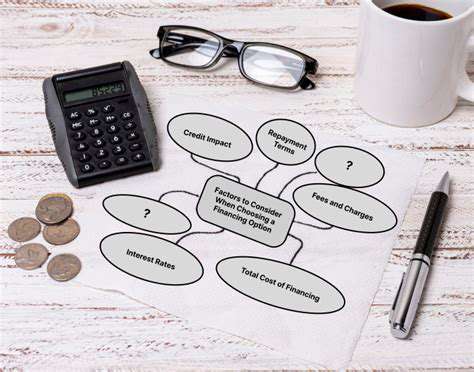

Factors Affecting ROI in Energy Efficiency

Several factors influence the ROI of energy efficiency measures, including the specific energy efficiency measures implemented, the energy prices in the region, and the building's characteristics. For instance, in areas with high energy costs, energy efficiency upgrades often yield a higher ROI. The type of building, its age, and its insulation levels also play a role in determining the effectiveness of various energy efficiency measures. Moreover, government incentives and rebates can significantly impact the overall ROI of an energy efficiency project.

Analyzing Different Energy Efficiency Measures

Different energy efficiency measures, such as upgrading insulation, installing high-efficiency windows, or implementing smart building controls, have varying impacts on ROI. For example, while insulation upgrades may have a relatively lower upfront cost, their long-term energy savings can often lead to a substantial ROI over time. Conversely, more expensive measures like installing solar panels can have a higher upfront cost but potentially offer a higher ROI over time, depending on the region's solar irradiance and government incentives.

Long-Term ROI and Sustainability

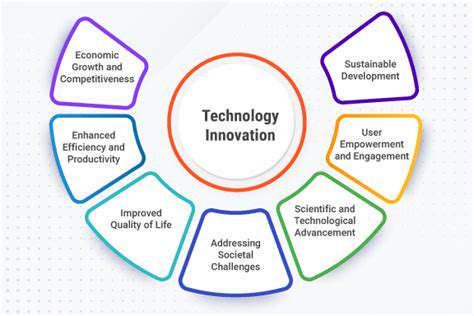

Focusing solely on the initial ROI can be insufficient when evaluating energy efficiency measures. A holistic approach must consider the long-term implications on sustainability, operational costs, and environmental impact. Projects with a potentially lower initial ROI might still be financially beneficial in the long run due to reduced maintenance costs, improved occupant comfort, and a reduced carbon footprint. A comprehensive analysis should include not only financial aspects but also environmental and social benefits.

Enhancing Sustainability and Environmental Performance

Improving Operational Efficiency

Implementing energy audits in the automotive sector is crucial for enhancing operational efficiency and reducing the environmental footprint of vehicle manufacturing and operation. These audits meticulously analyze energy consumption patterns across various stages, from material sourcing and production to testing and final assembly. By pinpointing energy-intensive processes and identifying areas for improvement, manufacturers can optimize their energy use, leading to significant cost savings and reduced reliance on fossil fuels. This, in turn, translates to a more sustainable and financially viable business model, attracting environmentally conscious consumers and investors.

Through detailed analysis of energy consumption data, energy audits reveal opportunities for process optimization, equipment upgrades, and the implementation of energy-efficient technologies. This data-driven approach allows for the identification of specific inefficiencies, enabling targeted interventions rather than broad, generalized solutions. For instance, an audit might reveal that a particular machine is consuming excessive energy due to outdated motor technology. This insight allows for the prompt replacement of this equipment with energy-efficient alternatives, minimizing waste and maximizing resource utilization throughout the entire production process.

Reducing Environmental Impact

Energy audits play a pivotal role in minimizing the environmental impact of automotive manufacturing and operation. By meticulously tracking and analyzing energy consumption, manufacturers can identify sources of greenhouse gas emissions and develop strategies to reduce their overall environmental footprint. This includes exploring opportunities for renewable energy integration, optimizing energy-intensive processes, and promoting the use of sustainable materials throughout the production cycle. The detailed data gathered during these audits enables the development of targeted emission reduction strategies, ultimately contributing to a more sustainable automotive industry.

Beyond reducing emissions, energy audits can help evaluate the environmental impact of materials used in vehicle production. This evaluation considers the life cycle of materials, from extraction to disposal, and identifies opportunities to use recycled or renewable resources. By understanding the environmental impact of different materials, manufacturers can make informed decisions about material sourcing and selection, promoting the use of sustainable alternatives. This comprehensive approach to environmental impact assessment leads to the creation of more environmentally friendly vehicles and contributes to a more sustainable automotive industry.

Furthermore, energy audits can be used to assess the environmental impact of vehicle operation. This includes analyzing the energy efficiency of different vehicle models and identifying opportunities to reduce fuel consumption. By evaluating factors like aerodynamics, engine efficiency, and tire friction, manufacturers can develop more fuel-efficient vehicles, ultimately reducing their environmental impact during operation.