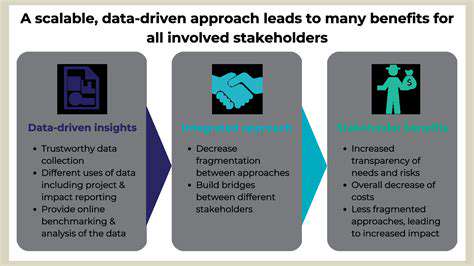

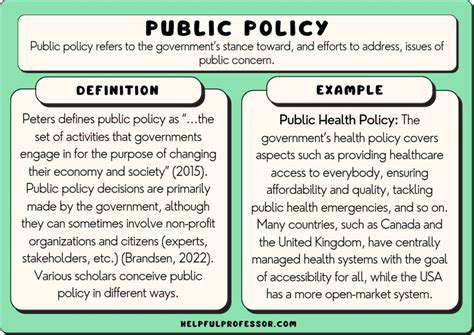

Environmentally friendly adhesives represent a cornerstone of sustainable auto manufacturing. These next-generation bonding solutions must deliver exceptional performance while using renewable ingredients and minimizing ecological harm. Breakthroughs in adhesive science are enabling manufacturers to achieve this delicate balance between performance and sustainability.

Maintaining Performance Standards

Sustainability cannot come at the expense of quality in automotive applications. Green adhesives must meet or exceed traditional standards for bond strength, durability, and resistance to extreme conditions. Only by achieving these benchmarks can eco-friendly adhesives ensure vehicle safety and longevity.

Overcoming Production Scale Challenges

The automotive industry faces significant hurdles in scaling up sustainable material production. Widespread adoption of biological adhesives requires establishing reliable supply networks, refining manufacturing techniques, and optimizing production costs. Addressing these challenges is essential for making sustainable materials the industry standard rather than the exception.

End-of-Life Vehicle Considerations

True sustainability extends to how vehicles are disposed of or recycled. Modern adhesives must be designed with disassembly and material recovery in mind. This forward-thinking approach helps create a circular economy in automotive manufacturing, reducing waste and environmental harm.

Consumer Influence on Market Dynamics

Public perception plays a pivotal role in driving sustainable innovation. As buyers become more environmentally conscious, automakers must clearly communicate the benefits of green materials. Educating consumers about eco-friendly adhesives and their environmental advantages will be crucial for widespread acceptance and adoption.

The Future of Automotive Bonding: A Sustainable Outlook

Innovative Materials and Methods

Automakers continue pushing boundaries to enhance vehicle performance through lighter, safer designs. Bonding technology has become indispensable in this pursuit, with an especially bright future ahead. Cutting-edge materials like advanced composites and high-performance polymers are revolutionizing vehicle construction, enabling lighter yet stronger designs that improve fuel efficiency. These developments are critical for reducing emissions and advancing sustainability goals.

Simultaneously, bonding techniques are becoming more sophisticated through specialized adhesives and precision application methods. These advancements create more durable connections, enhancing structural integrity - a vital factor in vehicle safety.

Enhanced Longevity and Dependability

Modern bonding solutions offer remarkable improvements in component durability. Advanced adhesives create more resilient vehicle parts that better withstand stress, leading to longer service life and lower maintenance expenses. This proves particularly valuable for components facing harsh operating conditions, ensuring consistent performance over extended periods.

Streamlined Production Economics

Bonding technologies present significant cost-saving opportunities in manufacturing. By replacing traditional welding and riveting, automakers can simplify assembly processes and accelerate production. The resulting efficiency gains reduce costs while the decreased material requirements further enhance the economic benefits.

Superior Safety Performance

Bonding technology contributes substantially to vehicle safety beyond structural integrity. Advanced bonding methods facilitate the creation of lighter, stronger components that improve crash protection. This innovation helps absorb impact energy more effectively during collisions, potentially reducing injury severity for occupants.

Environmental Benefits

The transition to advanced bonding solutions offers significant ecological advantages. Lighter vehicle construction and reduced manufacturing waste contribute to a substantially smaller environmental footprint. This aligns perfectly with global efforts to create more sustainable transportation solutions while promoting responsible resource use throughout the production cycle.

Convergence with Emerging Technologies

The evolution of automotive bonding intersects with multiple technological advancements. Integration with smart sensors and embedded electronics paves the way for intelligent, connected vehicle systems. This combination enables continuous structural monitoring and early problem detection. The development of sensor-equipped bonding solutions represents a particularly promising research direction for the industry.