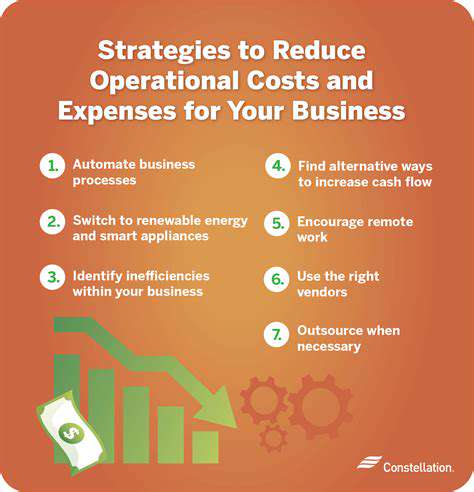

Streamlining Processes for Efficiency

Businesses today face mounting pressure to cut costs without sacrificing quality. One proven method is streamlining internal workflows. Careful analysis of existing processes often reveals redundancies that, when eliminated, yield substantial time and resource savings. This lean approach not only trims expenses but enhances productivity and customer satisfaction through faster, more reliable service delivery.

Effective resource allocation forms the backbone of process optimization. Whether managing personnel, equipment, or materials, strategic deployment prevents waste while aligning all teams toward shared objectives. Regular workflow audits help maintain this efficiency over time.

Optimizing Supply Chain Management

Modern supply chains represent both a significant expense and opportunity for savings. Smart companies continuously evaluate procurement, storage, and transportation processes. Tactics include renegotiating supplier contracts, adopting advanced inventory systems, and refining logistics strategies.

Sophisticated inventory tracking solutions enable businesses to maintain ideal stock levels, avoiding both shortages and costly overstock situations. These systems provide real-time visibility into supply chains, allowing for data-driven decisions that reduce carrying costs while ensuring product availability.

Leveraging Technology for Automation

Digital transformation offers powerful tools for cost reduction. Automating repetitive tasks through specialized software and machinery dramatically decreases labor requirements while boosting accuracy. From automated invoicing to robotic process automation in manufacturing, these solutions free human workers for higher-value activities.

Enterprise Resource Planning (ERP) systems take this further by integrating all business functions. These platforms provide comprehensive oversight of operations, enabling better coordination between departments and identifying additional efficiency opportunities.

Implementing Cost-Effective Training Programs

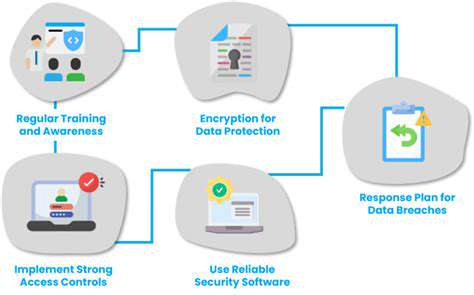

Employee development represents a strategic investment rather than an expense. Well-trained staff make fewer errors, work more efficiently, and require less supervision - all contributing to bottom-line savings. Effective programs combine hands-on training with ongoing professional development to keep skills current.

Internal expertise development also reduces reliance on expensive external consultants. Cross-training employees creates a more versatile workforce capable of handling diverse challenges without additional hiring.

Enhancing Energy Efficiency

Utility costs form a substantial portion of operational budgets for many enterprises. Simple measures like LED lighting upgrades and smart thermostats offer quick returns. More comprehensive approaches include energy audits to identify waste and equipment upgrades to more efficient models.

Forward-thinking companies are exploring renewable energy options. While requiring initial investment, solar arrays and other green solutions provide long-term cost stability while demonstrating environmental responsibility.

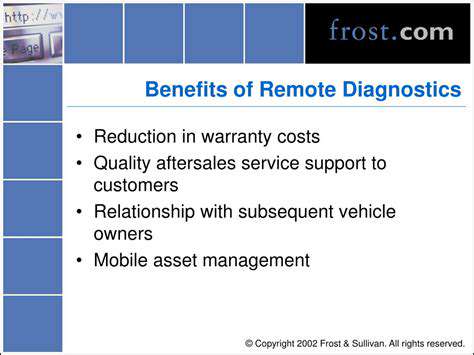

Improving Customer Relations for Reduced Costs

Exceptional customer service directly impacts operational expenses. Satisfied customers generate fewer support requests and remain loyal longer. This reduces customer acquisition costs while increasing lifetime value.

Companies prioritizing customer experience often see organic growth through word-of-mouth referrals, significantly lowering marketing expenditures. Proactive service approaches that anticipate needs before they become problems further enhance these benefits.

Improved Safety and Reduced Accidents: A Paradigm Shift in Logistics

Enhanced Driver Training Programs

Contemporary logistics operations demand comprehensive driver education that extends beyond basic vehicle operation. Modern programs incorporate hazard recognition, defensive driving techniques, and emergency response training. Regular refresher courses and performance evaluations help maintain high safety standards across fleets.

Addressing driver fatigue requires both technological and procedural solutions. Electronic logging devices ensure compliance with hours-of-service regulations, while optimized routing minimizes unnecessary overtime. These measures collectively reduce accident risks while improving driver wellbeing.

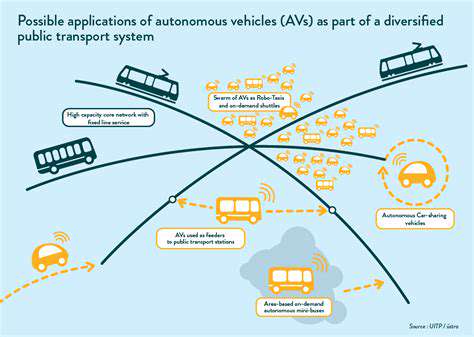

Advanced Vehicle Technology Integration

Modern safety technologies are revolutionizing logistics operations. Collision avoidance systems, lane departure warnings, and automatic emergency braking actively prevent accidents before they occur. These systems complement driver skills rather than replace them, creating multiple layers of protection.

While fully autonomous vehicles remain in development, existing semi-autonomous features already enhance safety. Adaptive cruise control and automated lane keeping reduce driver fatigue on long hauls, particularly in heavy traffic conditions.

Optimized Route Planning and Management

Intelligent routing systems analyze multiple variables to determine the safest, most efficient paths. Real-time traffic monitoring allows for dynamic adjustments to avoid congestion, construction zones, and hazardous weather conditions. This proactive approach minimizes exposure to high-risk situations.

Enhanced communication networks enable continuous coordination between dispatchers and drivers. Instant updates about changing road conditions or emergency situations allow for immediate course corrections when needed.

Improved Infrastructure and Road Safety

Logistics companies increasingly collaborate with government agencies to identify and address infrastructure deficiencies. Targeted investments in road maintenance, improved signage, and better lighting create safer driving environments for all motorists.

Private sector initiatives complement public infrastructure improvements. Many fleets now install dash cams and telematics systems that identify dangerous road segments, allowing companies to adjust routes accordingly and report hazards to authorities.

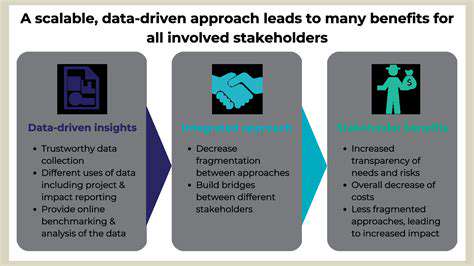

Data-Driven Safety Analysis and Predictive Modeling

Advanced analytics transform accident prevention from reactive to proactive. By examining patterns in historical incident data, companies identify high-risk scenarios before they result in crashes. This intelligence informs targeted training programs and operational adjustments.

Continuous monitoring systems provide real-time safety metrics. These platforms alert managers to developing risks, enabling immediate intervention to prevent accidents rather than merely investigating them after they occur.

Increased Capacity and Flexibility: Expanding Operational Possibilities

Enhanced Production Capabilities

Capacity expansion enables businesses to capitalize on market opportunities. Strategic investments in equipment and facilities allow for increased output without compromising quality. This growth potential attracts new customers while strengthening relationships with existing clients through improved reliability.

Expanded production necessitates supply chain adaptations. Developing alternative supplier relationships and implementing just-in-time inventory strategies help maintain smooth operations during periods of increased demand.

Improved Resource Allocation

Additional capacity provides the flexibility to deploy resources where they create the most value. This might involve shifting production between facilities based on demand or reallocating personnel to priority projects. Such agility proves invaluable in dynamic market conditions.

Enhanced forecasting capabilities accompany increased capacity. With greater ability to meet demand fluctuations, companies can optimize inventory levels more precisely, reducing carrying costs while maintaining service levels.

Adaptability to Changing Market Demands

Operational flexibility serves as a competitive differentiator. Businesses that can quickly adjust production volumes or product mixes gain first-mover advantages when market conditions shift. This responsiveness builds customer confidence and market share.

Scalable operations allow for efficient testing of new products or markets. Companies can pilot innovations without major capital commitments, then scale successful initiatives rapidly when they prove viable.

Streamlined Workflows and Processes

Increased capacity often reveals process inefficiencies that went unnoticed at lower volumes. Addressing these bottlenecks through automation or reorganization creates compounding efficiency gains. The resulting improvements benefit all operations, not just expanded capacity areas.

Standardized procedures developed during expansion often improve quality consistency. Documented best practices ensure all teams, regardless of location or shift, maintain the same high standards.

Enhanced Customer Service and Fulfillment

Additional capacity directly translates to better customer experiences. Faster order processing, reduced backorders, and more flexible delivery options all contribute to higher satisfaction levels. These service improvements frequently justify premium pricing.

The ability to handle demand surges without service degradation builds customer trust. Clients appreciate suppliers who consistently meet needs regardless of market fluctuations or seasonal peaks.

Cost Optimization and Efficiency Gains

Scale efficiencies often emerge with increased capacity. Fixed costs spread across greater output volumes, while bulk purchasing reduces material costs. These savings can be reinvested in further improvements or passed to customers to strengthen competitive position.

Larger operations attract top talent seeking career growth opportunities. The resulting human capital improvements drive innovation and operational excellence throughout the organization.

Future Implications and the Potential for Growth: Shaping the Industry

The Rise of Automation and its Economic Impact

Workplace automation continues advancing across industries. While displacing some traditional roles, it simultaneously creates new opportunities in system design, maintenance, and oversight. Forward-looking organizations invest in workforce transition programs to smooth this evolution.

The productivity gains from automation often enable business expansion that creates more jobs than the technology eliminates. However, these new positions typically require different skill sets, emphasizing the importance of continuous learning initiatives.

The Impact of Emerging Technologies on Consumption Patterns

AI-driven personalization reshapes consumer expectations. Customers increasingly anticipate tailored experiences and instant access to products and services. Companies meeting these expectations gain significant competitive advantages in their markets.

IoT integration creates new service and revenue opportunities. Connected products generate valuable usage data while enabling innovative subscription and service models that build recurring revenue streams.

Global Economic Interdependence and Trade Relationships

Modern supply chains span continents, creating both opportunities and vulnerabilities. Diversified sourcing strategies help mitigate risks while taking advantage of global specialization. Regional production hubs are gaining importance as companies balance efficiency with resilience.

The Role of Sustainable Practices in Economic Development

Environmental responsibility now drives purchasing decisions for both consumers and businesses. Sustainable operations reduce regulatory risks while appealing to environmentally conscious market segments. Many companies find green initiatives simultaneously cut costs and enhance brand value.

The Future of Financial Markets and Investment Strategies

Digital transformation reaches financial services through blockchain, AI-driven analytics, and decentralized finance. These innovations create new investment vehicles while increasing market transparency. Investors must balance traditional fundamentals with emerging opportunities in this evolving landscape.