Optimizing Manufacturing Processes and Energy Efficiency

Improving Material Selection for Reduced Emissions

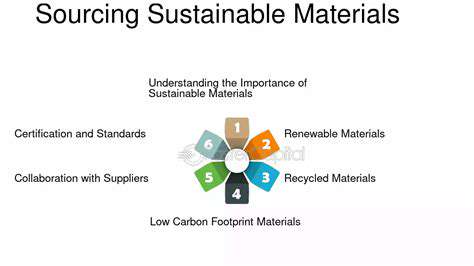

A crucial aspect of optimizing manufacturing processes for reduced emissions is the careful selection of materials. Choosing materials with lower embodied carbon throughout their lifecycle, from extraction to disposal, significantly decreases the environmental footprint of the final product. This involves considering the energy intensity of the material production process, the potential for recycling or reuse, and the material's overall durability and lifespan. By selecting materials with inherent sustainability features, manufacturers can significantly reduce the emissions associated with their products.

Furthermore, exploring alternative materials like recycled metals or composites can create a positive environmental impact. These materials often require less energy to produce compared to virgin materials, resulting in a lower carbon footprint. Thorough lifecycle assessments (LCAs) are essential tools to evaluate the environmental impact of different material choices, helping manufacturers make informed decisions that minimize their environmental impact and reduce emissions.

Lean Manufacturing Principles for Efficiency Gains

Implementing lean manufacturing principles can lead to significant improvements in energy efficiency and emission reduction throughout the manufacturing process. This involves streamlining production lines, minimizing waste, and maximizing resource utilization. Techniques like just-in-time inventory management, reducing setup times, and eliminating unnecessary steps can dramatically decrease energy consumption and emissions associated with transportation and storage.

Waste reduction is paramount in this context. Minimizing material waste through precise cutting techniques, optimized designs, and effective scrap management reduces the overall environmental impact of the manufacturing process. Lean principles encourage a culture of continuous improvement, fostering an environment where every employee is engaged in identifying and eliminating inefficiencies, ultimately decreasing emissions.

Optimizing Energy Consumption in Manufacturing Processes

Energy efficiency improvements are essential for reducing emissions in manufacturing. Identifying areas where energy is wasted and implementing energy-saving technologies and strategies, such as advanced process controls, can significantly reduce the environmental impact. This includes upgrading to more energy-efficient machinery, implementing motion-controlled automation, and optimizing lighting and heating systems within the manufacturing facility.

Advanced Process Controls and Automation

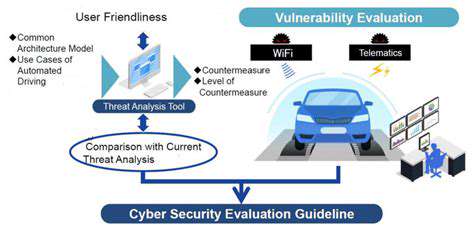

Advanced process controls and automation play a critical role in optimizing manufacturing processes and reducing emissions. Implementing real-time monitoring systems and feedback loops allows manufacturers to identify and address inefficiencies rapidly, reducing energy consumption and optimizing resource utilization.

Automation, in many cases, can also lead to reduced human error and improved consistency in production, lowering the overall energy consumption and minimizing waste generation. Integrating these technologies into the manufacturing process can significantly contribute to the reduction of emissions and enhance overall efficiency.

Sustainable Supply Chain Management

A sustainable supply chain is crucial for reducing emissions in the automotive industry. This involves working with suppliers who share a commitment to environmental responsibility and minimizing transportation emissions through optimized logistics and the use of alternative transportation methods.

Emission Monitoring and Reporting

Implementing robust emission monitoring and reporting systems is essential for tracking progress and identifying areas needing further improvement. This includes accurately measuring emissions from various stages of the manufacturing process, setting targets for reduction, and regularly reporting on progress. Regular auditing and data analysis can help identify trends and patterns, allowing for proactive adjustments to processes and strategies.

Employee Training and Awareness

Investing in employee training and awareness programs is crucial for fostering a culture of sustainability within the manufacturing facility. Educating employees about the importance of reducing emissions and providing them with the skills and knowledge to implement energy-saving practices can significantly impact the overall environmental performance of the company. This includes training on waste reduction techniques, energy conservation measures, and sustainable material handling practices.

Electrification and the Rise of EVs

The Growing Demand for Electric Vehicles

The global shift towards sustainable transportation is driving a surge in demand for electric vehicles (EVs). Consumers are increasingly recognizing the environmental benefits of EVs, opting for them over traditional gasoline-powered cars, which contribute significantly to air pollution. This growing demand is not just a trend, but a fundamental shift in consumer preference, fueled by both government incentives and evolving environmental consciousness.

The rising popularity of EVs is a direct result of their lower emissions and reduced reliance on fossil fuels. This shift is expected to continue, as governments worldwide implement policies to encourage the adoption of electric vehicles.

Technological Advancements in Battery Technology

One of the key drivers behind the EV revolution is the rapid advancement in battery technology. Innovations in battery chemistry, manufacturing processes, and energy density are making EVs more affordable, practical, and reliable. These advancements are crucial for increasing the range and performance of electric vehicles, addressing a key concern for early adopters.

Improved battery technology is directly impacting the consumer experience, making EVs a more viable option for a wider range of drivers. This progress is paving the way for a future where electric vehicles are not just a niche market but a mainstream transportation choice.

Government Incentives and Policies

Governments worldwide are implementing various incentives and policies to encourage the adoption of EVs. These policies often include tax credits, subsidies, and favorable charging infrastructure programs. These initiatives aim to reduce the cost of EVs and make them more accessible to a wider range of consumers.

Government support is crucial in driving mass adoption of electric vehicles. These policies are fostering a positive feedback loop, where increased adoption leads to further investment and innovation in the EV sector.

Infrastructure Development for EV Charging

The widespread adoption of EVs is inextricably linked to the development of robust charging infrastructure. Public charging stations, both fast-charging and slow-charging, are vital for convenience and range anxiety mitigation. The expansion of charging networks is crucial for addressing the concerns of potential EV buyers.

Impact on the Automotive Industry

The electrification of the automotive industry is leading to significant changes in the way vehicles are designed, manufactured, and marketed. Automakers are investing heavily in EV technology and adapting their manufacturing processes to accommodate the production of electric vehicles. This shift is reshaping the entire automotive landscape, creating new opportunities and challenges for companies.

The transition to electric vehicles is fundamentally altering the automotive industry, forcing companies to adapt or risk becoming obsolete. This transformation is creating a dynamic and competitive environment that will likely lead to further innovation.

Environmental Benefits and Reduced Emissions

A key advantage of EVs is their significantly lower carbon footprint compared to gasoline-powered vehicles. By reducing reliance on fossil fuels, EVs contribute to cleaner air and a healthier environment. The reduction in harmful emissions is a major factor in the growing public support for electric vehicles.

Electric vehicles are a crucial step towards a more sustainable transportation future. Their adoption is a critical component in addressing climate change and improving air quality worldwide. This environmental benefit is increasingly important to consumers.

The Future of Electrification

The future of transportation is undoubtedly electric. Continued advancements in battery technology, government support, and infrastructure development will further accelerate the shift towards EVs. This transition is not just about individual vehicles; it's about a complete transformation of the transportation sector, impacting everything from urban planning to industrial processes.

The widespread adoption of electric vehicles is inevitable and will drastically change the way we travel. The long-term benefits, both environmental and economic, are driving the rapid evolution of this transition, promising a future where transportation is both sustainable and efficient.