Minimizing Energy Consumption and Waste Generation in Welding Operations

Optimizing Welding Parameters for Energy Efficiency

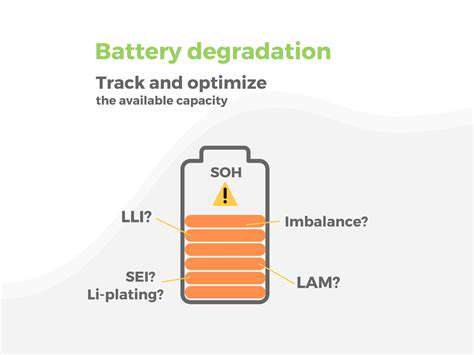

Welding processes consume significant amounts of energy, primarily through the heat required to melt the base metals. Optimizing welding parameters like current, voltage, travel speed, and wire feed rate can drastically reduce energy consumption. Implementing advanced control systems that monitor and adjust these parameters in real-time can further enhance efficiency by minimizing energy waste during the welding process, leading to substantial reductions in operational costs and a smaller carbon footprint.

For example, employing pulse welding techniques can precisely control the energy input, minimizing heat-affected zone formation and reducing the amount of energy required to achieve a strong weld. This targeted energy delivery translates directly into energy savings and a more environmentally friendly approach to welding.

Utilizing Energy-Efficient Welding Equipment

Choosing welding equipment with high energy efficiency ratings is crucial. Modern inverters and other advanced technologies are designed to deliver the necessary power while consuming less electricity. Investing in such equipment can significantly reduce the overall energy consumption of a welding operation, lowering energy bills and promoting sustainability.

Furthermore, incorporating features like power factor correction in welding transformers can improve the efficiency of the electrical system, reducing energy losses throughout the process. This approach not only saves energy but also improves the overall power quality of the facility.

Implementing Waste Reduction Strategies

Welding operations often generate significant amounts of waste, including slag, dross, and excess filler material. Implementing robust waste management strategies, such as proper segregation and recycling programs, can minimize the environmental impact of these materials. This includes the careful handling and disposal of hazardous materials generated during the welding process, ensuring compliance with environmental regulations.

Furthermore, exploring the use of alternative filler materials and consumables that are readily recyclable or biodegradable can reduce the overall waste stream. Implementing such strategies requires a proactive approach to waste management, incorporating it into the standard operating procedures of the welding shop.

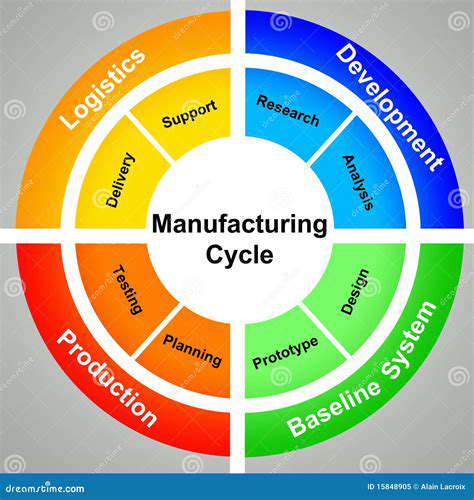

Employing Lean Manufacturing Principles

Applying lean manufacturing principles to welding operations can streamline workflows and reduce material waste. Techniques like 5S, value stream mapping, and just-in-time inventory management can optimize material handling, minimizing the amount of excess material used in the welding process. This approach can also reduce the number of defects, resulting in less rework and less material wasted.

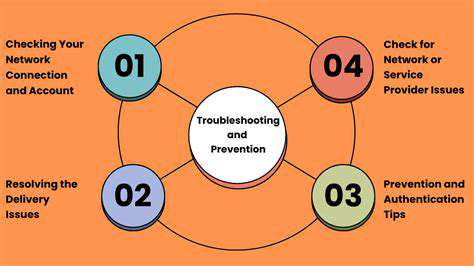

Enhancing Operator Training and Awareness

Proper training and awareness programs for welding operators are essential to minimizing energy consumption and waste generation. Educating operators on best practices, energy-efficient techniques, and the importance of proper material handling can significantly impact the overall efficiency of the welding process. Training programs should include demonstrations and hands-on exercises to reinforce the practical application of these techniques, ensuring operators are equipped to make informed decisions.

Empowering operators with the knowledge and skills to identify and correct issues related to energy consumption and waste generation can lead to substantial improvements in environmental performance. This involves a commitment to continuous improvement and operator engagement in the sustainability efforts of the welding operation.

Promoting Research and Development in Eco-Friendly Welding Technologies

Ongoing research and development are crucial for developing innovative eco-friendly welding technologies. Exploration of alternative welding processes, such as laser welding or friction stir welding, that offer lower energy consumption and reduced waste generation is essential. Further research into the development of more sustainable filler materials and consumables can also contribute to a significant reduction in the environmental impact of welding operations.

Investing in research and development in this area fosters the creation of more environmentally friendly and energy-efficient welding practices, supporting the transition to a more sustainable industrial landscape. This includes collaboration between research institutions, manufacturers, and welding companies to accelerate the adoption of these advancements.

The Role of Sustainable Materials in Eco-Friendly Automotive Welding

The Importance of Sustainable Sourcing

Sustainable materials play a crucial role in minimizing environmental impact throughout the product lifecycle. From the extraction of raw materials to the manufacturing process and ultimately the disposal or recycling of the finished product, conscious choices about materials can significantly reduce our footprint on the planet. This involves careful consideration of the environmental costs associated with each stage, and a commitment to reducing resource depletion and pollution.

Prioritizing renewable resources and minimizing the use of virgin materials are key aspects of sustainable sourcing. By selecting materials derived from recycled content or rapidly renewable sources, manufacturers can significantly lessen their reliance on finite resources and contribute to a more circular economy. This approach not only reduces the strain on ecosystems but also fosters innovation in material science, leading to the development of more sustainable and efficient alternatives.

Environmental Impact of Material Choices

The environmental impact of material choices extends far beyond the initial manufacturing process. The entire lifecycle of a product, from its creation to its eventual disposal, should be evaluated to assess the full range of environmental consequences. This includes considering the energy consumption required for extraction, processing, and transport of raw materials, as well as the potential for pollution during these stages. Careful consideration of these factors is vital for creating truly sustainable products.

By selecting materials with lower environmental footprints, companies can significantly reduce their carbon emissions and lessen their contribution to air and water pollution. This commitment to environmental stewardship demonstrates a responsible approach to business practices and positions companies as leaders in sustainable innovation. The choice of material can directly impact the environmental impact of the entire product lifecycle.

The impact also extends to the end-of-life stage. The ease and efficiency of recycling or composting a material are critical factors to consider. Materials that can be easily recycled or composted reduce the amount of waste that ends up in landfills. This consideration is a key element of long-term sustainability.

Economic and Social Benefits of Sustainable Materials

The shift towards sustainable materials offers a multitude of economic and social benefits beyond environmental considerations. Innovation in sustainable materials often leads to the creation of new jobs and industries, driving economic growth in the green sector. This includes roles in material research, development, and manufacturing, as well as the expansion of recycling and reuse infrastructure.

Sustainable materials can also contribute to improved public health by reducing exposure to harmful chemicals and pollutants. Choosing materials that are safe for human use and for the environment is essential for long-term well-being. By prioritizing sustainable materials, companies can enhance their brand reputation and attract environmentally conscious consumers, creating a competitive advantage in the market.