CCS

CCS, or Combined Charging System, is a widely used fast-charging standard for electric vehicles (EVs). It's a popular choice for its global adoption and compatibility across many European and Asian countries. CCS connectors are characterized by their robust design, enabling them to handle high charging currents, which translates to faster charging speeds compared to some other charging standards. Understanding the different CCS variations and their voltage capabilities is crucial for ensuring compatibility with various charging stations and maximizing charging efficiency. The CCS standard has several variations, each with its own connector design and specifications, which can impact compatibility with specific EVs. This diversity necessitates careful consideration of the charging infrastructure and vehicle compatibility when selecting an EV.

A key advantage of CCS is its versatility. It's designed to handle a range of charging voltages, facilitating both fast and slower charging rates. This adaptability allows for seamless integration into various charging networks and enables EVs to receive power from a wider range of charging stations. This flexibility is critical for EV drivers who need reliable charging access across different regions and locations. The design of the CCS plug is also noteworthy, featuring a unique shape that prevents incorrect connections. This safety feature prevents accidental connections with other charging standards, minimizing the risk of damage or malfunction.

CHAdeMO

CHAdeMO, or Charge de Mode, is another prominent fast-charging standard, primarily prevalent in Japan and some other parts of Asia. While CHAdeMO has historically been a significant charging standard in its region, its adoption rate has decreased in recent years due to the rise of CCS and other charging standards. Despite this, knowledge of CHAdeMO is still important for understanding the evolution of EV charging infrastructure globally. The CHAdeMO system is known for its relatively high charging speeds, allowing for quick replenishment of battery power. However, its reduced presence in other parts of the world may limit charging availability for some EV drivers.

The compact design of the CHAdeMO connector, while contributing to its speed, can also present limitations in terms of charging power compared to some of the more recent charging standards. This difference in charging capability should be considered when comparing charging options, particularly in regions where CHAdeMO infrastructure is less prevalent. A driver's charging needs and the availability of charging stations will strongly influence the choice between CHAdeMO and other charging standards. CHAdeMO's historical influence on EV charging infrastructure still warrants recognition, although its current usage is less widespread.

Type 2: The Common European Standard

The Historical Context of the Standard

The Common European Standard, Type 2, emerged from a confluence of factors, including the increasing need for interoperability among European manufacturers and the desire to establish a unified market. This standard aimed to address inconsistencies in product specifications across different European nations, ultimately facilitating trade and consumer choice. The historical context is crucial to understanding the standard's significance and its lasting impact on the European industrial landscape.

This historical evolution involved a complex interplay of political, economic, and technological forces. The desire for a unified Europe played a significant role, alongside the growing need for efficient industrial processes and standardized components. The development of the standard was not a simple, linear progression but rather a multifaceted endeavor that involved collaboration between various stakeholders, including governments, industries, and regulatory bodies. This process was not without its challenges, but the ultimate result was a crucial step toward European economic integration.

Key Specifications and Features

Several key specifications defined the Type 2 Common European Standard. These specifications covered everything from material composition and dimensions to manufacturing processes and quality control measures. The focus was on ensuring that products adhering to the standard met specific quality benchmarks and safety standards, thereby promoting consumer trust and confidence.

The precise details of these specifications varied depending on the specific product category. However, a common thread ran through them all: the commitment to quality and consistency. This ensured that the products were not only functional but also reliable and safe for use.

Impact on Consumer Choice

The introduction of the Type 2 Common European Standard had a significant impact on consumer choice. Consumers could now readily identify products that met specific quality and safety standards. This transparency fostered trust and confidence in the market, allowing consumers to make more informed decisions.

Manufacturing and Production Processes

The standard significantly impacted manufacturing and production processes across Europe. Manufacturers were required to adapt their production lines and quality control systems to meet the new specifications. This process often involved substantial investments in new equipment and training for personnel. This adaptation period was challenging but ultimately led to greater efficiency and productivity in the long run.

The standardization of components and processes allowed for greater efficiency in supply chains. It fostered a more interconnected and streamlined European manufacturing landscape.

Economic Benefits of Standardization

The Type 2 Common European Standard brought numerous economic benefits to the European economy. It facilitated trade between countries, reduced costs associated with product variations, and fostered a more competitive market. The reduced need for costly product modifications and repairs led to significant savings for businesses and consumers alike.

The Standard's Evolution and Future Implications

The Common European Standard, Type 2, has evolved over time to address new technological advancements and changing market demands. Ongoing revisions and updates ensure the standard remains relevant in the face of technological progress and evolving consumer needs. The future implications of this standard include the potential for further integration within the European market and the continued development of innovative products and technologies.

The lasting impact of Type 2 is undeniable. It has shaped the European industrial landscape, fostered trust, and continues to influence the development of standards in the region. This standard's legacy will likely be felt for many years to come.

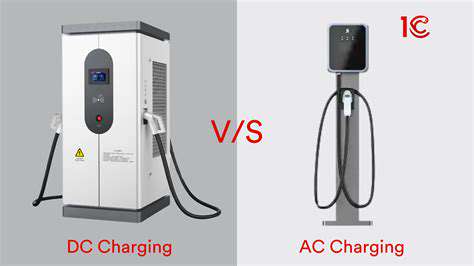

AC vs. DC Charging Cables: Understanding the Difference

Understanding AC Charging Cables

AC charging cables, commonly used for devices like laptops and smartphones, utilize alternating current (AC) to power the devices. This type of charging typically involves a wall adapter that converts the AC power to direct current (DC) before it reaches the device. Understanding the intricacies of AC charging is key to ensuring optimal performance and preventing potential damage to your devices.

The AC charging process is a crucial component of modern electronics, enabling the consistent flow of energy needed for operation. The conversion from AC to DC, handled by the adapter, is fundamental to this process. Many factors, like the voltage and amperage ratings, can heavily influence the charging speed and efficiency.

DC Charging Cables: An Overview

DC charging cables, often used in electric vehicles (EVs) and other specialized devices, directly deliver direct current (DC) power. This contrasts with AC charging, which necessitates a conversion step. DC charging is significantly faster than AC charging, making it ideal for situations where rapid charging is required.

Key Differences Between AC and DC Charging

A fundamental difference lies in the type of current delivered. AC charging uses alternating current, requiring a conversion to DC before reaching the device, while DC charging transmits direct current directly. This difference in current type significantly impacts the charging speed and the overall charging process.

Another key difference lies in the charging infrastructure. AC charging typically relies on standard wall outlets, while DC charging often utilizes specialized charging stations, particularly prevalent in the EV market. This variance in infrastructure dictates the applicability of each method.

Factors Affecting Charging Cable Selection

Several factors influence the choice of charging cable, including the device's specifications, the charging environment, and the desired charging speed. Matching the cable's voltage and amperage ratings to the device's requirements is essential to prevent potential damage and ensure optimal charging performance. Consider the charging speed when choosing the cable, as different cables offer varying charging rates.

The environment in which the charging will take place is also a factor. Extreme temperatures or high humidity levels might affect the cable's performance or lifespan. Therefore, selecting a cable suitable for the environment is crucial.

Safety Considerations for Charging Cables

Ensuring safety is paramount when using charging cables. Always inspect the cable for any damage, such as frayed wires or exposed conductors. Damaged cables pose a significant safety risk due to the potential for electrical shocks or fires. Never use a damaged charging cable to avoid potential hazards.

Furthermore, adhering to the manufacturer's instructions is crucial for safe and effective charging. Improper use can lead to unforeseen problems and potentially damage your device or create a safety hazard. Proper use of charging cables is essential for maintaining the longevity of your devices.